|

American

Locomotive Company (Alco or ALCO) in World War Two

Schenectady, NY

1903-1969

This page updated 4-11-2022.

An American Auto

Industry in World War Two Special Edition

The American Locomotive Company

(Alco), like several other American manufacturers of steam locomotives,

was picked by the U.S. Army to produce tanks and self-propelled guns

during World War Two. Because their tanks were similar to those

produced by Chrysler, Fisher Body, and Ford, and were used by many

American tankers, Alco is being added to this website. A more

direct connection to the American Automobile industry is the fact that

Alco built automobiles from 1905-1913. Another direct connection

to the American Automobile industry is that Walter Chrysler was the

plant manager of the Alco automobile plant in Providence, Rhode Island

in 1911. He left Alco to go to work for Buick in Flint, MI.

Alco was more than just a

locomotive and armored vehicle manufacturer during World War Two.

The company produced a broad range of products, as shown below, that

helped win World War Two.

Alco was formed by the

merger of the Schenectady Locomotive Works and seven other

companies. With another acquisition in 1905, it became the second

largest locomotive company in the United States. During its

existence, it produced 75,000 locomotives. Most of them were steam;

but it made the conversion to diesel-electric after World War Two.

The American Locomotive Company plant in Schenectady, NY

won the Army-Navy "E" award two times.

The American Locomotive Company Railway Steel-Spring plant in Latrobe,

PA won the Army-Navy "E" award four times.

American Locomotive Company World War Two

Production Statistics: 157 RSD-1 diesel electric road switcher

for the U.S. Army, 200 2-10-0 Decapod steam locomotives, 2,985 medium

tanks, 3,314 M7 self-propelled 105mm howitzers, industrial heat

exchangers, industrial pressure vessels, industrial pre-fabricated pipe,

90 marine boilers, forged gun barrels for 75mm pack howitzers, 76mm

anti-tank guns, 90mm anti-aircraft guns and 155mm howitzers, marine

steam turbine generator shafts, Liberty ship kingposts, masts, and top

masts, springs for U.S. Navy fighter aircraft and for many U.S. Navy

ship applications 105mm howitzer and 155mm Long Tom gun carriages. Alco was 34th

in dollar value of World War Two production contracts.

-

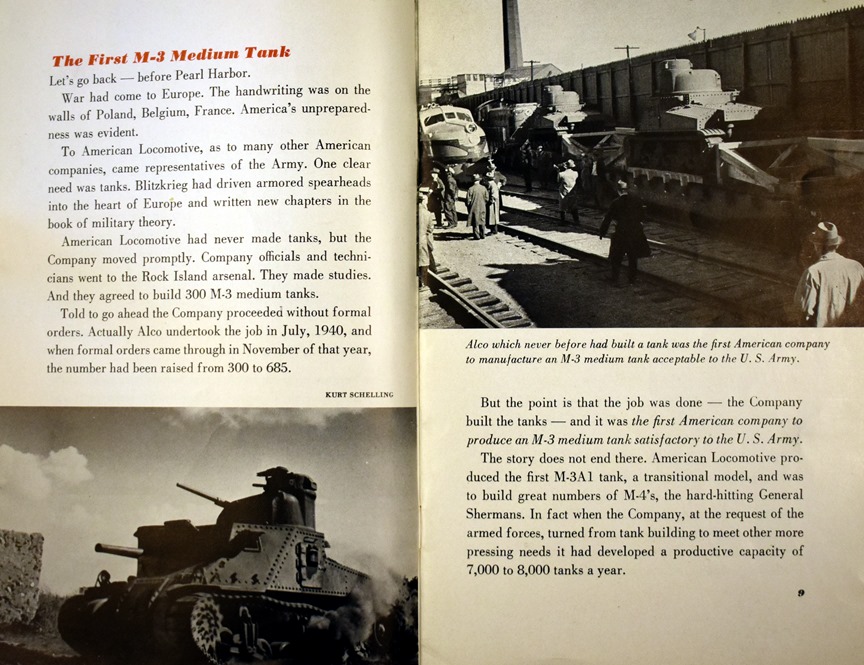

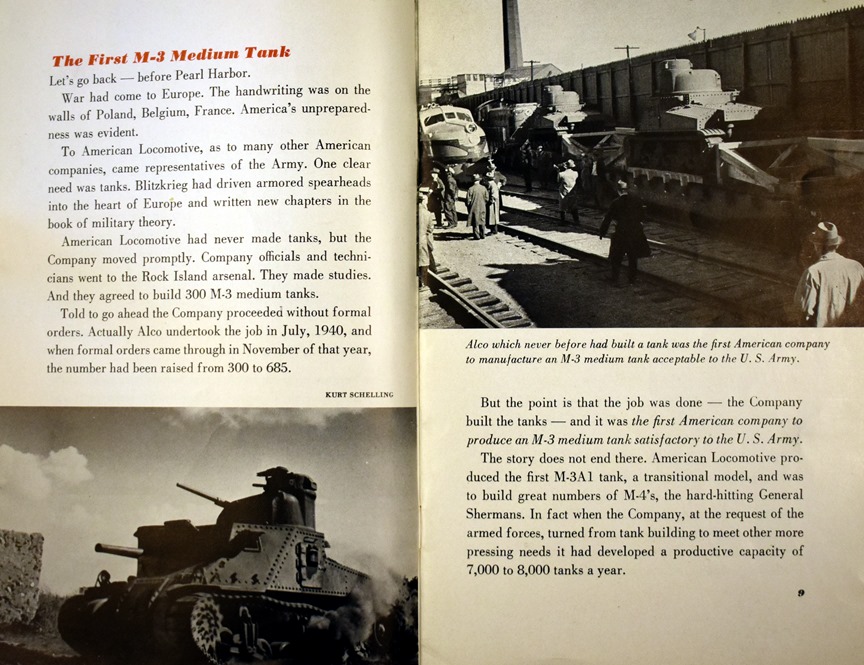

Alco started work on the

M3 medium tank in July 1940 with a promised order of 300 tanks from

the U.S. Army. In November 1940 Alco received a contract for

685 M3 and M3A1 medium tanks. It was the first company to

build an M3 that met all of the requirements of the U.S. Army.

These were built in the Schenectady plant.

-

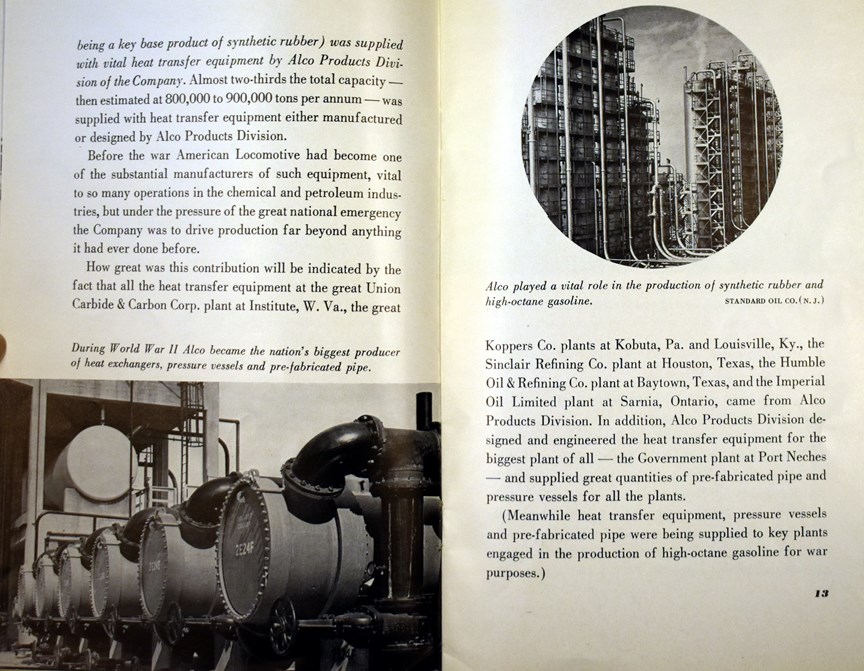

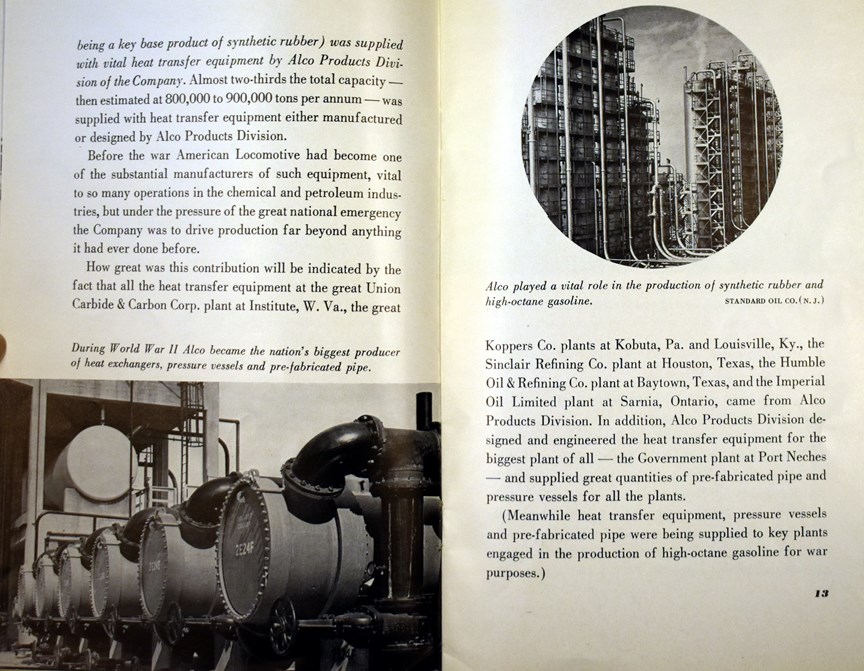

Alco's Product Division

provided half of the heat exchangers used in producing synthetic

rubber during World War Two.

-

Industrial heat

exchangers, industrial pressure vessels, and pre-fabricated

pipe were used by companies producing high octane gasoline for the

war effort.

-

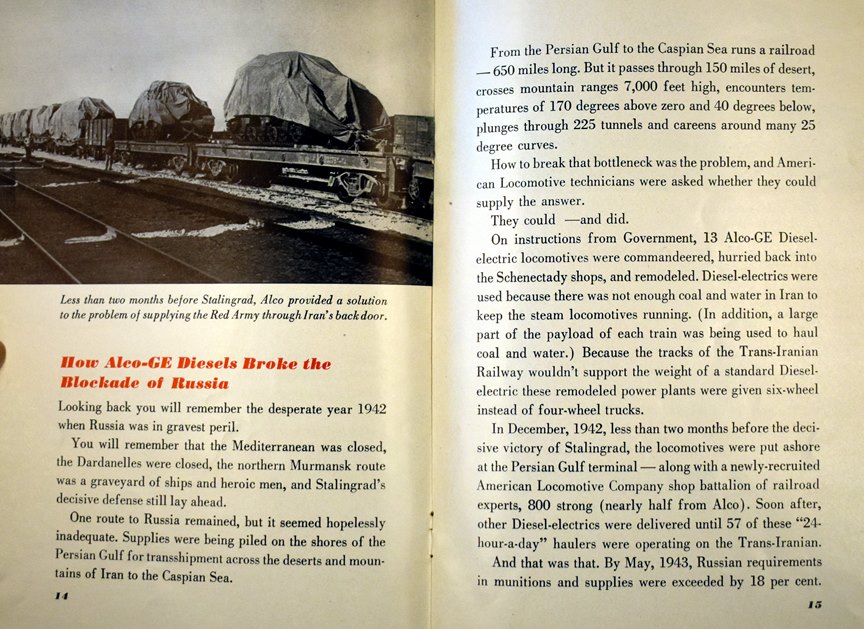

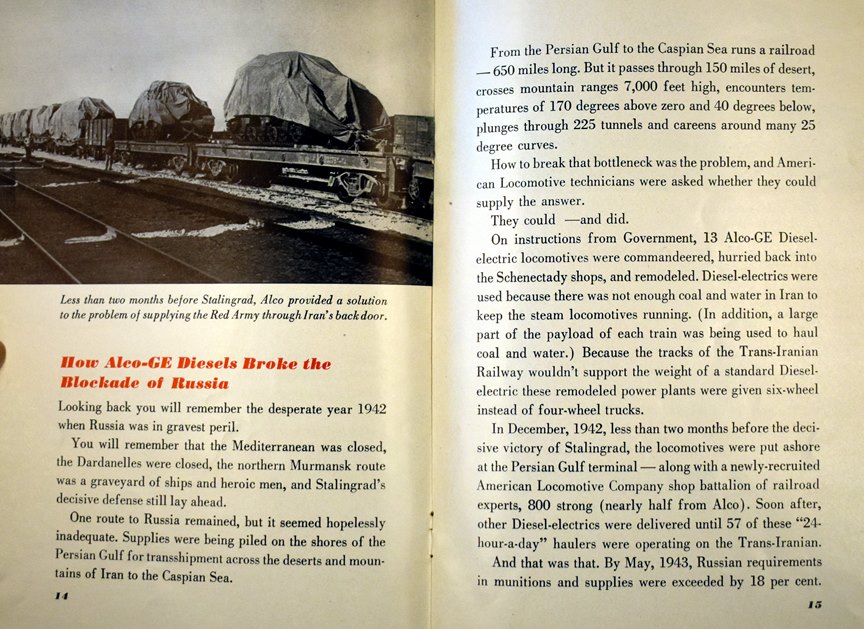

Alco reconditioned the

original thirteen Alco-GE diesel electric locomotives for use in

Iran to pull supply trains carrying Lend-Lease supplies to Russia.

-

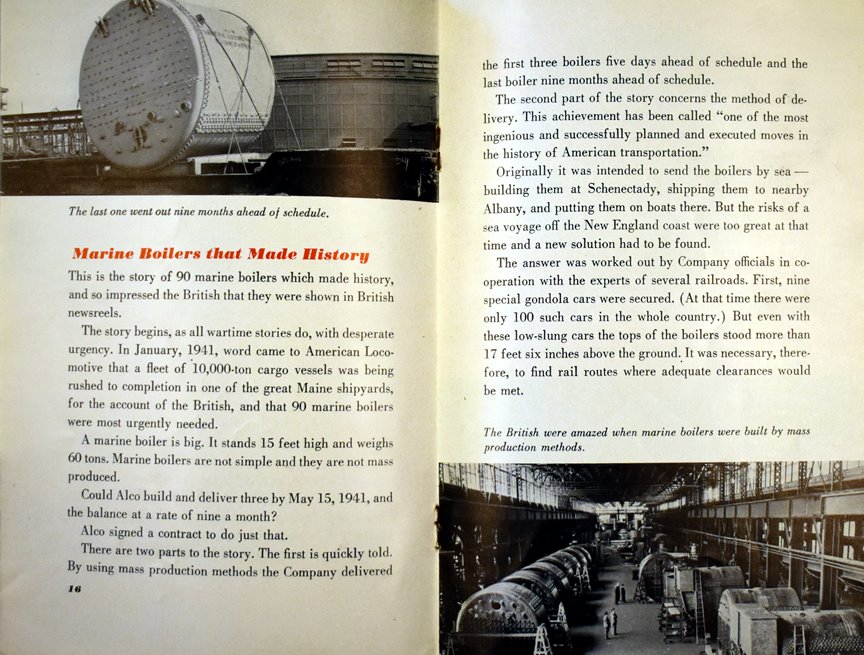

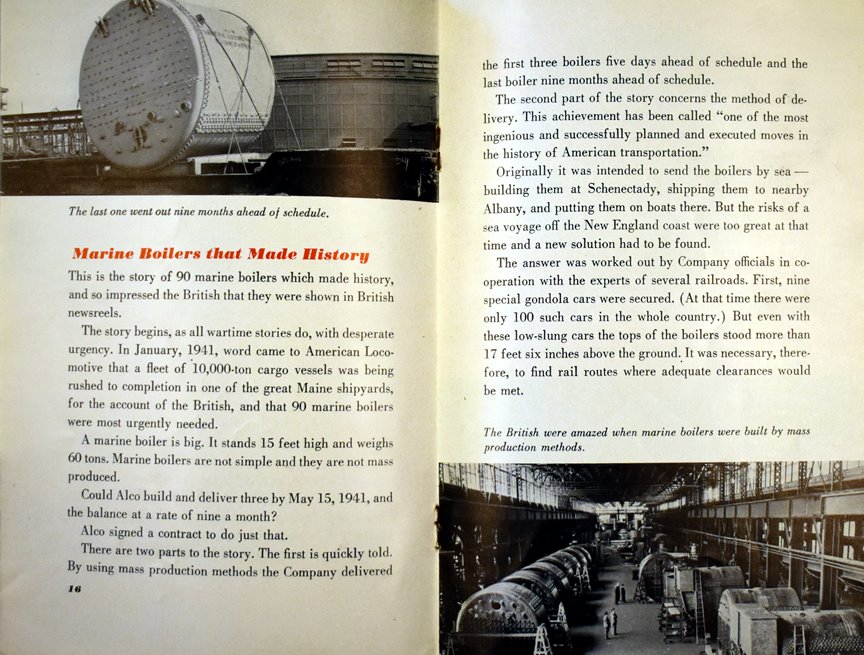

In 1941 Alco began

providing 90 marine boilers needed to complete a group of 10,000 ton

merchant ships being built in Maine for the British. The first

three boilers were completed five days ahead of schedule, with the

entire order completed nine months ahead of schedule. The

marine boilers weighed 60 tons and were 15 feet high. Special

rail cars were needed to ship them from Schenectady, NY to Maine.

-

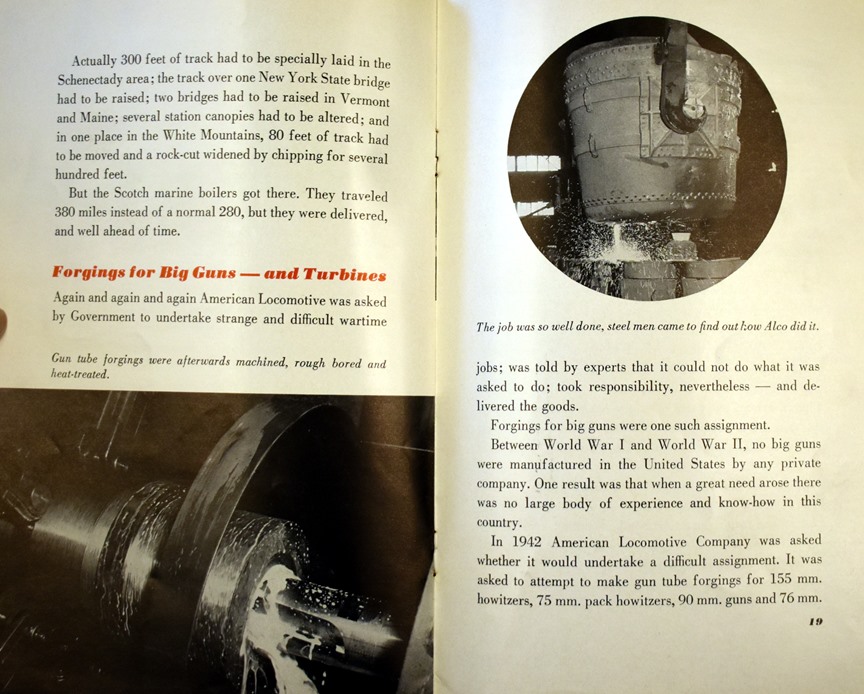

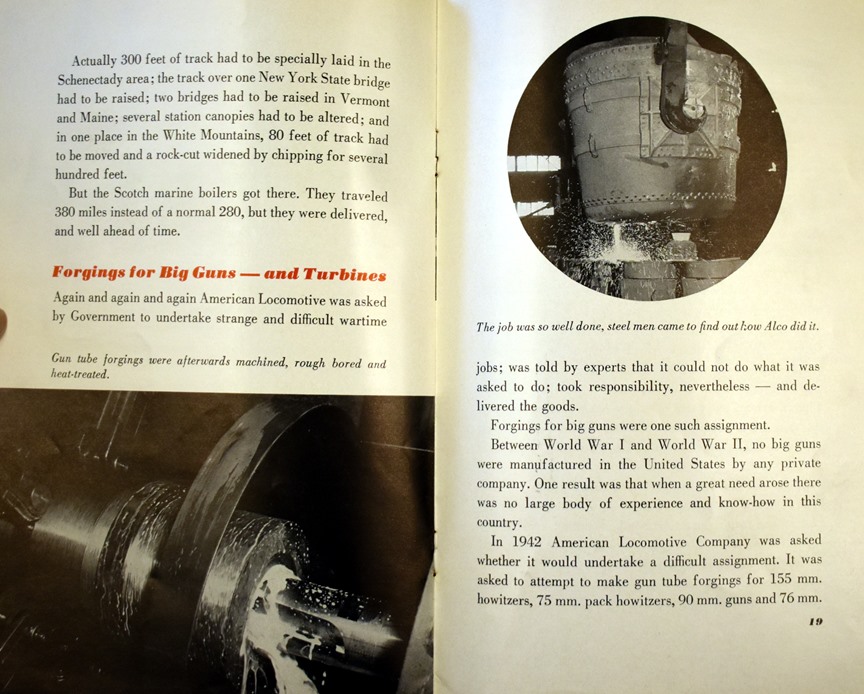

The several types of gun

barrels noted above were constructed from ingots produced at its

Latrobe, PA steel plant and then forged, machined, rough-bored, and

heat treated at Schenectady, NY.

-

In 1942 Alco was

requested by the U.S. Navy to produce 200 steam turbine generator

shafts for its ship building program. It completed this order

and continued to supply more of these items as the war continued.

-

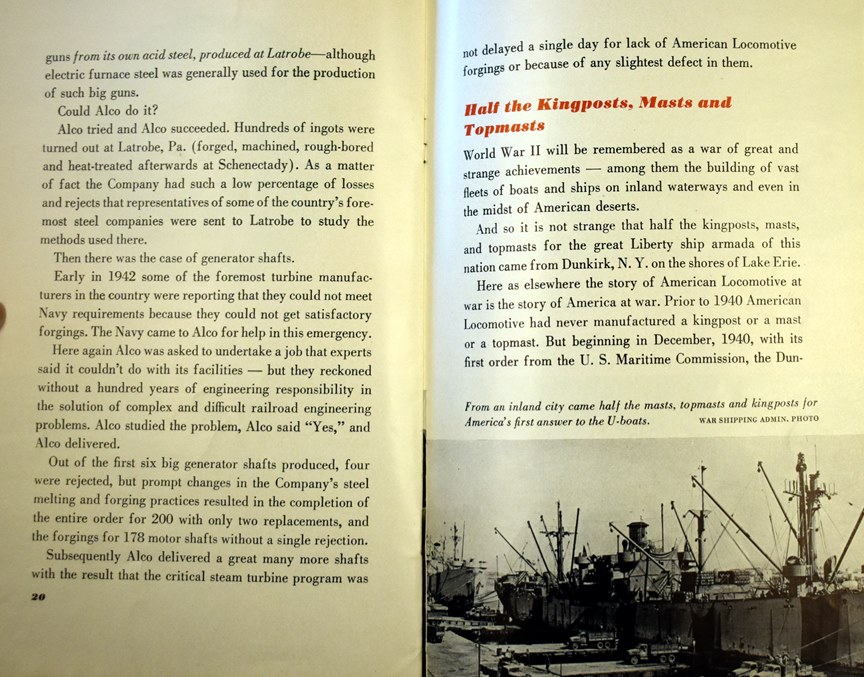

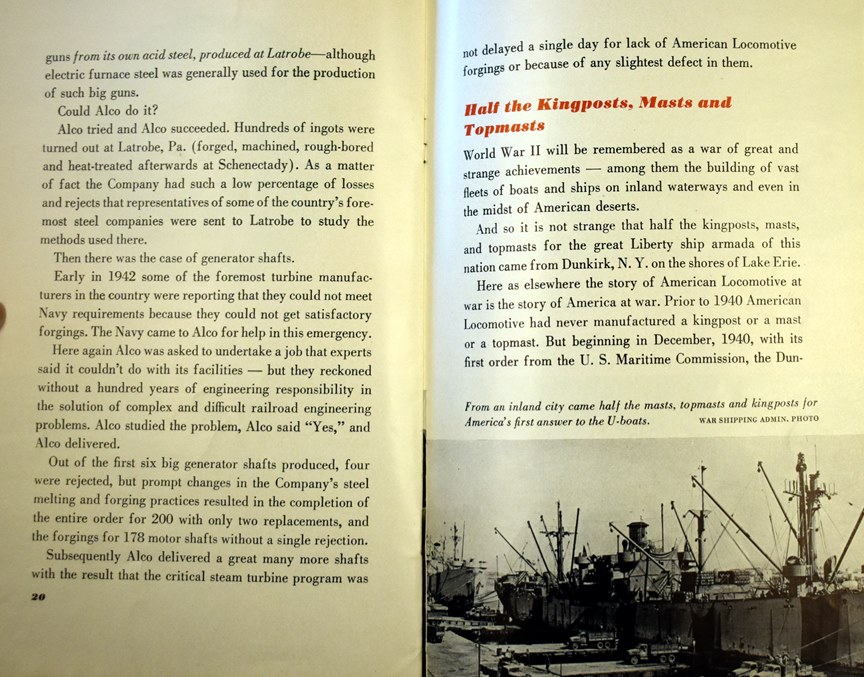

The Alco plant at

Dunkirk, NY, on Lake Erie, built Liberty ship kingposts, masts, and

top masts. The first order was received in December 1940 from

the U.S. Maritime Commission. Production of these products soon ramped up to

2,300 tons per month. The Dunkirk plant

supplied the three largest shipyards building Liberty ships with

their entire requirement of kingposts, masts, and top masts.

-

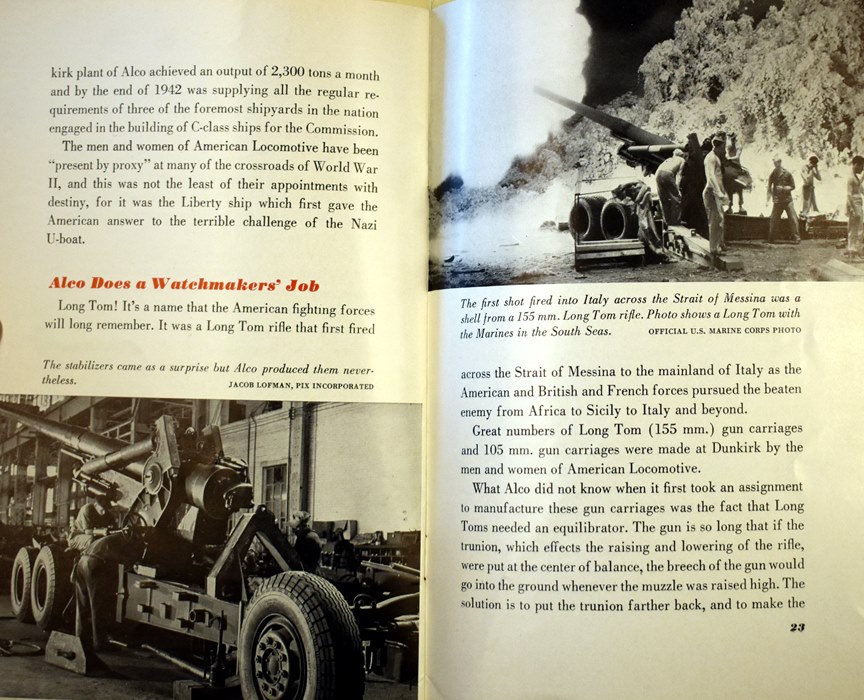

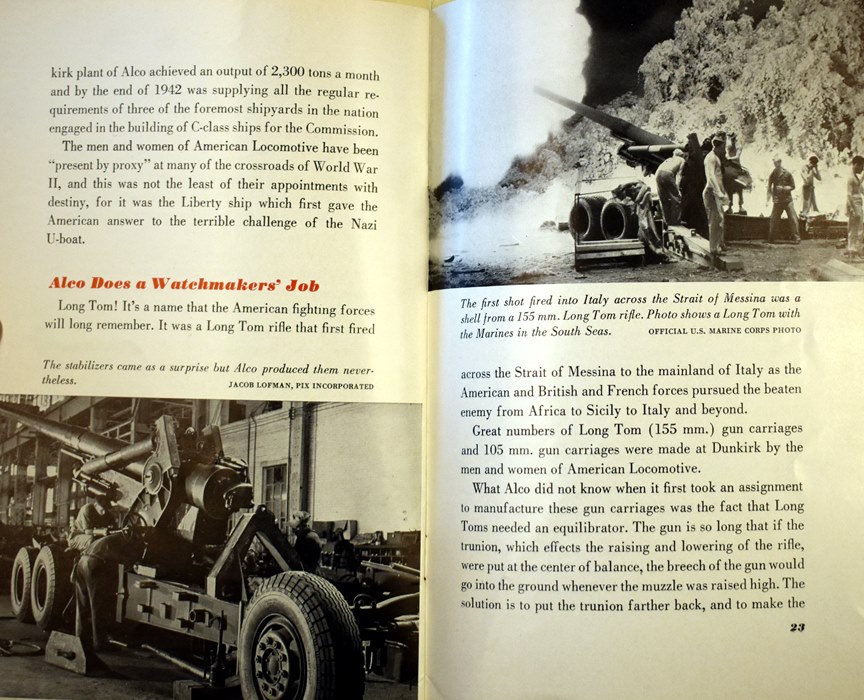

Dunkirk built 105mm

howitzer and 155mm Long Tom gun carriages.

-

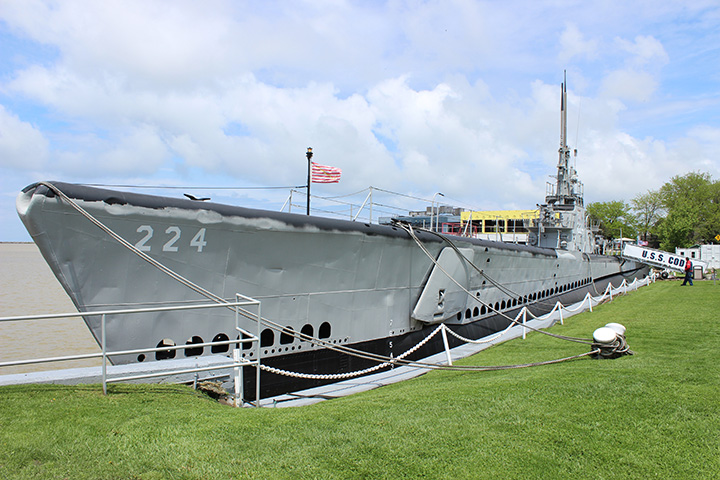

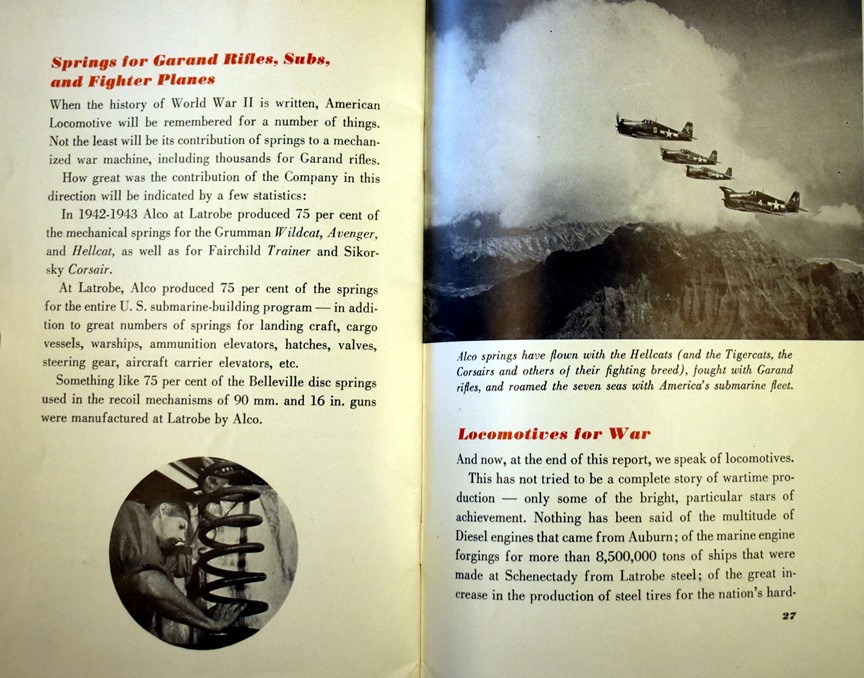

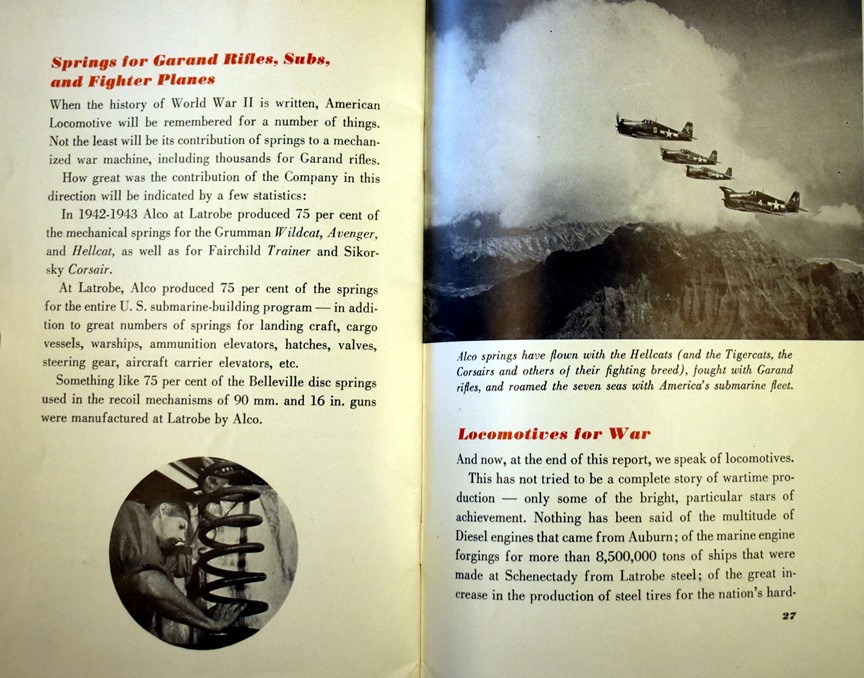

The Alco Latrobe, PA

plant supplied a large variety of springs utilized in many military

products. The plant supplied 75% of the springs in the F4F,

F6F,TBM, F4U, and PT-19. It also provided 75% of the springs for the

U.S. Navy submarines built during World War Two. Springs were

also built for other navy vessels. Belleville springs were

supplied for recoil mechanisms in 90mm anti-aircraft guns and

16-inch battleship main armament.

This is one of 157 RSD-1s that were built

for the U.S. Army during World War Two. The U.S. Army used 87,

thirteen of them for the Trans-Iranian Railroad. Seventy were

shipped to the Soviet Union in 1945. Only 58 made it, as twelve

were sunk while being shipped by U-boats. This example is

part of the Tennessee Valley Railroad Museum in Chattanooga, TN.

This Alco-built RSD-1 pulled Joseph Stalin's

train to the Potsdam Conference in July-August 1945.

A 2-10-0 Decapod on display in Russia.

This World War One era 2-10-0 Decapod was built

by Alco and is on display at the North Carolina Transportation Museum

in Spencer, NC.

American

Locomotive Company Tanks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Medium, M3 |

|

224 |

161 |

|

|

|

385 |

| Medium, M3A1 |

|

|

300 |

|

|

|

300 |

| Medium, M4(75) |

|

|

|

2,150 |

|

|

2,150 |

| Medium, M4A2(75) |

|

|

126 |

24 |

|

|

150 |

| Total |

|

224 |

587 |

2,174 |

|

|

2,985 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during WWII. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

|

American

Locomotive Company Gun Motor Carriages

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Carriage, Motor, 105 mm

howitzer, M7 |

|

|

2,028 |

786 |

500 |

|

3,314 |

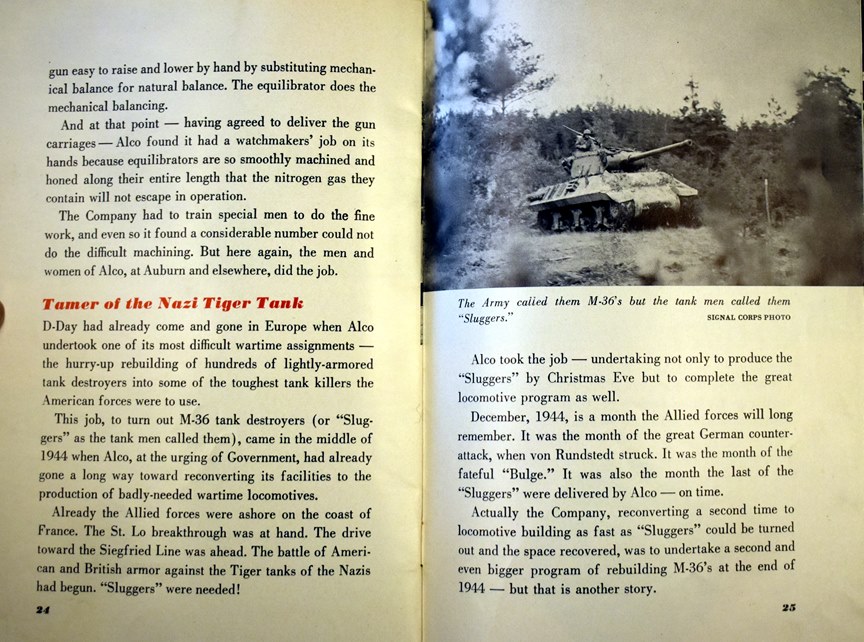

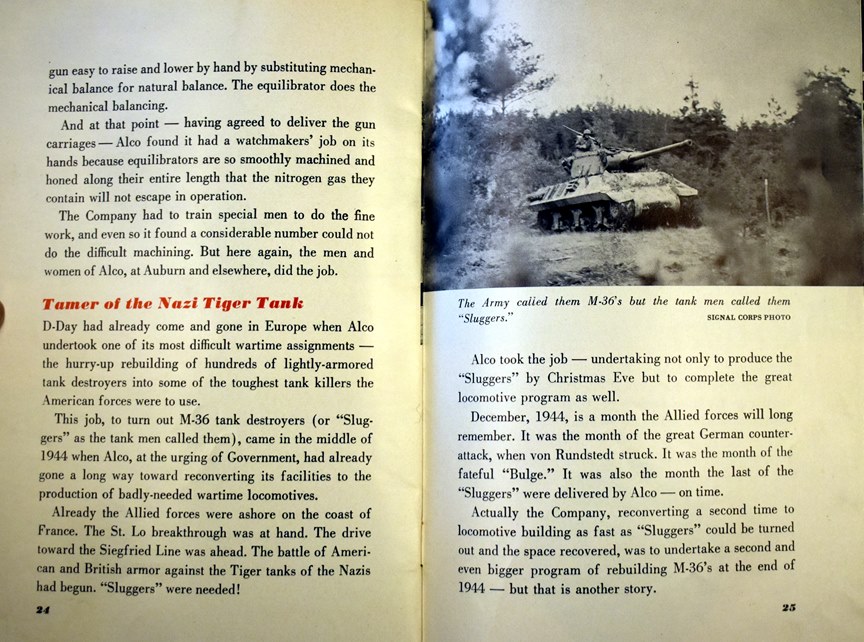

| Carriage, Motor, 90 mm gun, M36,

conversion |

|

|

|

|

413 |

|

413 |

| Carriage, Motor, 90 mm gum,

M36B2, conversion |

|

|

|

|

|

672 |

672 |

| Total |

|

|

2,028 |

786 |

913 |

672 |

4,399 |

-fortbenning-2018-107w-1.jpg)

How cool is this? The first Sherman

tank built by Alco was this M4A2, Serial Number 1405, built in September

1942. The Firefly turret with a British 17-pounder (76.2mm) main

gun was added at the end of, or after, World War Two. Serial Number

1405 was originally armed with a 75mm main gun. Author's photo

from the U.S. Army Armor and Cavalry

Collection, Fort Benning, GA.

-fortbenning-2018-107w-2.jpg)

Author's photo from the U.S. Army Armor and

Cavalry Collection, Fort Benning, GA.

-fortbenning-2018-107w-2.jpg)

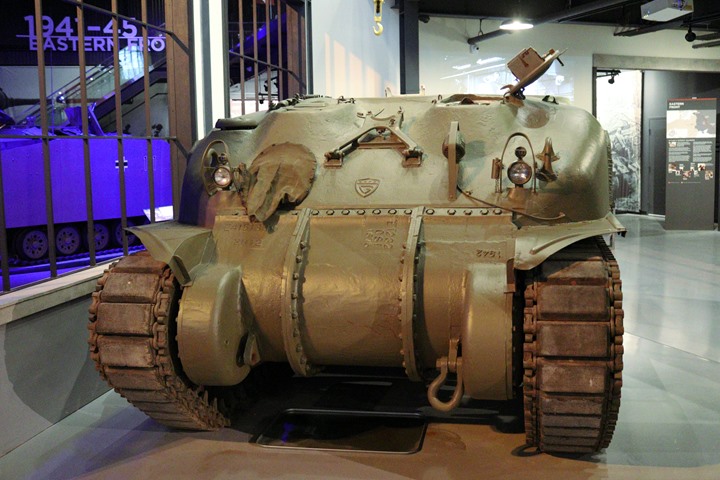

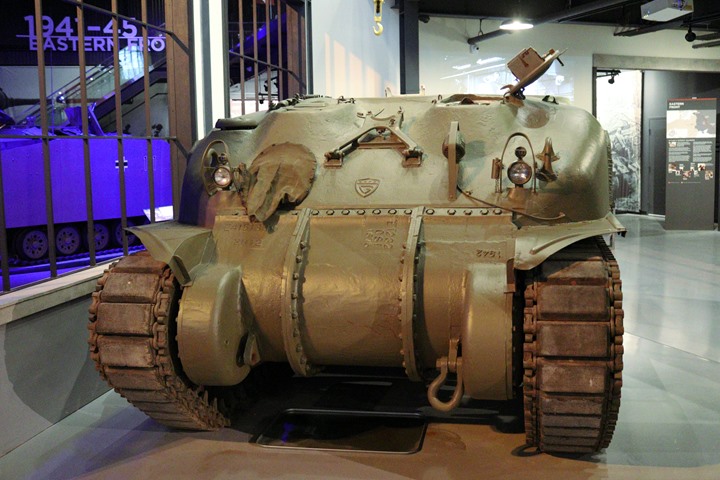

This is an Alco-built M4 Sherman tank,

Serial Number 3949, built April 1943. Author's photo from

the U.S. Army Armor and Cavalry Collection, Fort Benning, GA.

-fortbenning-2018-107w-1.jpg)

Author's photo from the U.S. Army Armor and

Cavalry Collection, Fort Benning, GA.

-crestviewfl-sn1765-2022-107w-1.jpg)

This Alco-built M4E9(75) is on display in

front of the Am Vets 35 in Crestview, FL. This is serial number

1765 and was built in April 1943. It is the oldest surviving Alco

M4. Author's photo added 4-22-2022.

-crestviewfl-sn1765-2022-107w-2.jpg)

Author's photo added 4-22-2022.

-crestviewfl-sn1765-2022-107w-3.jpg)

Author's photo added 4-22-2022.

-natlinfantrymuseum-sn25054-2018-107w-1.jpg)

This is an Alco-built M4, Serial Number

25054, constructed July 1943. Author's photo from the U.S.

Army Armor and Cavalry Collection, Fort Benning, GA. This is on

outdoor display at the National Infantry Museum, just outside the gate

to Fort Benning.

-natlinfantrymuseum-sn25054-2018-107w-2.jpg)

Author's photo from the U.S. Army Armor and Cavalry Collection, Fort

Benning, GA.

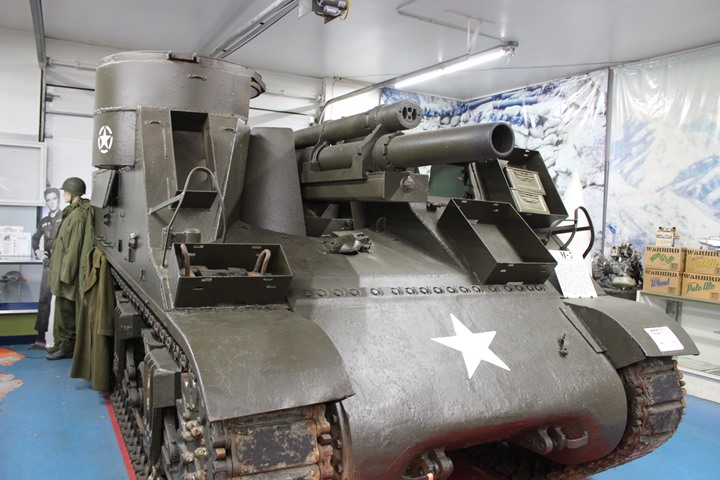

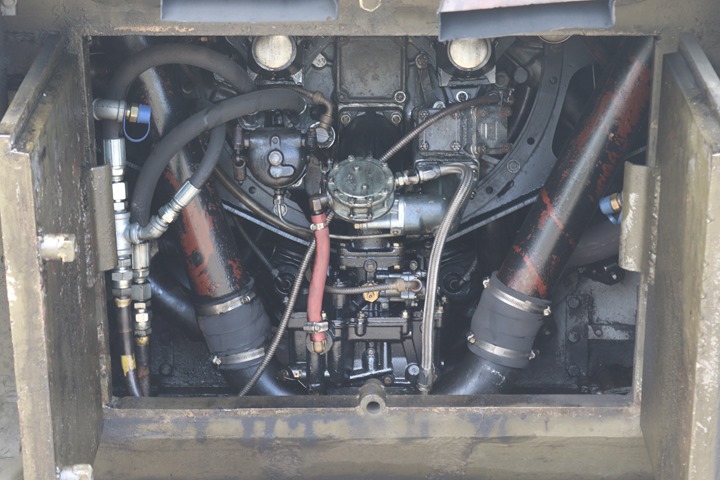

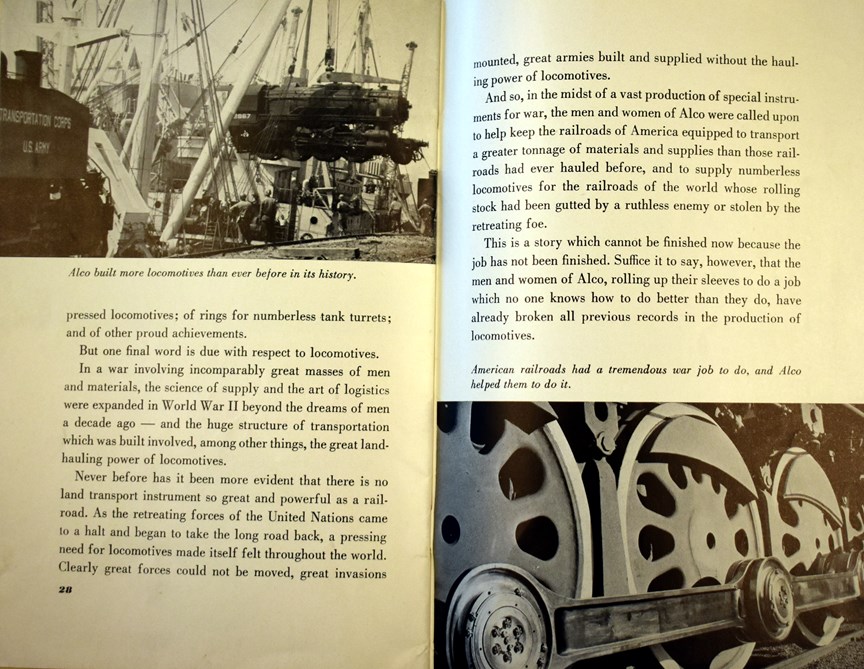

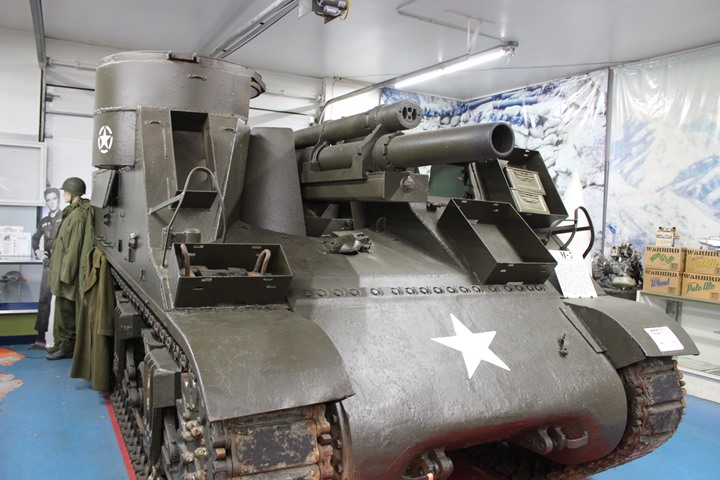

This M7 105mm Howitzer Motor Carriage is

owned the Virginia Museum of Military Vehicles. It was built by

Alco in November 1942 and carries Serial Number 1364.

Author's photo.

Alco M7 Serial Number 3248 is on display at

the Russell Military Museum in Zion, IL. It was built September

1944. Author's photo.

Author's photo.

Author's photo.

Alco produced carriages for the 155mm Long

Tom during World War Two. Author's photo added 9-30-2020.

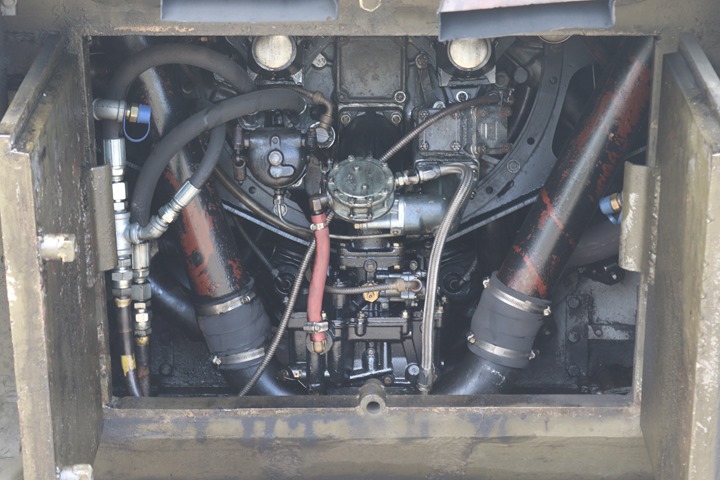

Springs are an important part of military

aircraft and perform necessary operations but are hidden from view.

Alco produced 75% for the Grumman F6F shown above. It also

produced 75% of the springs used in the F4F, TBM, F4U, and PT-19.

Author's photo added 9-30-2020.

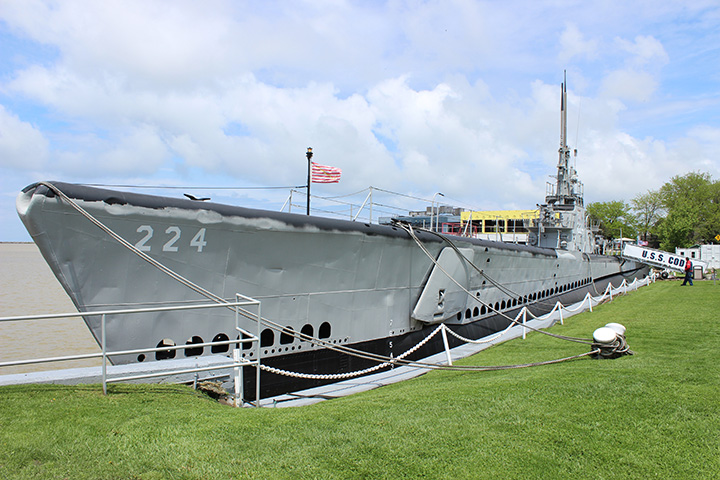

Alco also furnished 75% of the springs that

were used in American submarines during World War Two. Author's

photo added 9-30-2020.

The Belleville recoil springs in the 90mm

anti-aircraft gun were also built by Alco. Author's photo added

9-30-2020.

Montreal Locomotive

Works: In 1904 Alco acquired the Locomotive and Machine

Company of Montreal, Quebec, Canada. It was renamed the Montreal

Locomotive Works, which also produced tanks and self-propelled artillery

for the Commonwealth forces in World War Two.

Montreal Locomotive Works World War Two

Production Statistics: 1,949 Ram tanks (See Author's Note below), 188 M4A1 Grizzly

tanks, and 2,150 Sexton self-propelled artillery carriages. The

company also converted 200 M10A1 Wolverine tank destroyers to M36

Jackson tank destroyers. Late in the war, it converted another 52

M10 Wolverine tank destroyers to M36B2 Jackson tank destroyers.

Author's note: The number of Ram

Tanks built by Montreal Locomotive Works varies depending on the source.

The reported build quantities range from the 1,144, shown in the table

below, to 2,032 on the high end. One source indicates around 2,000

were built. I have chosen the total of 1,949 from "Fact Sheet No.

16: Ram Tank" by the Canadian War Museum. This is the most

well researched and comprehensive of the available sources on the Ram

Tank. It shows there were 50 Ram Mark I's built with 2-pounder

guns, 1,815 Ram Mark II's built with 6-pounder guns, and 84 Ram Mark II

Observation Posts with no guns. It could be that Detroit Ordnance

did the original ordering for the British Purchasing Commission.

Then after 1,144, the British or Canadians ordered the remainder.

After more than 75 years, we will never know. I will leave the

table below on the webpage just for reference. DDJ 10-31-2019.

|

Montreal

Locomotive Works Tanks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Medium, Ram I (British

Contract) |

|

31 |

19 |

|

|

|

50 |

| Medium, Ram II (British

Contract) |

|

|

1,094 |

|

|

|

1,094 |

| Total |

|

31 |

1,113 |

|

|

|

1,144 |

|

Montreal

Locomotive Works Gun Motor Carriages

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Carriage, Motor, 90 mm gun, M36,

conversion |

|

|

|

|

|

200 |

200 |

| Carriage, Motor, 90 mm gum,

M36B2, conversion |

|

|

|

|

|

52 |

52 |

| Total |

|

|

|

|

|

252 |

252 |

This Montreal Locomotive Works M4A1 Grizzly

is owned by WW2 Armor in Osteen, FL. Author's photo.

Author's photo.

This and the next three photos are of the

same WW2 Armor's M4A1 Grizzly, but now on the beach at the 2019 Conneaut

D-Day 75 at Conneaut, OH. Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

The M4A1 Grizzly in action at Conneaut 2019.

Author's photo added 8-22-2019.

This M4A1 Grizzly is part of an Arsenal for

Democracy display at the American Heritage Museum. The tank is

awaiting the installation of the turret in the display. Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

This M4A1(75) Grizzly is part of the

collection of the U.S. Army Armor and Cavalry Collection at Fort Benning,

GA. It is shop No. 93. Author's photo added 10-9-2019.

This Sexton is on display at the Indiana

Military Museum in Vincennes, IN. Author's photo.

Author's photo.

Author's photo.

This Sexton is part of the collection of the

Wheels of Liberation located in New Oxford, PA. The very nice

restoration includes an all-weather tarp, which is a nice addition to

the vehicle. This was on display at the 2019 MVPA convention.

Author's photo added 10-9-2019.

The AAF Museum in Danville, VA is the home

of this Montreal built Sexton. Author's photo.

The Russell Military Museum in Zion, IL is

also the home for this Sexton, along with its Alco-built M7.

Author's photo.

In Ottawa, Ontario, visitors can see this

Sexton at the Canadian War Museum. Author's photo.

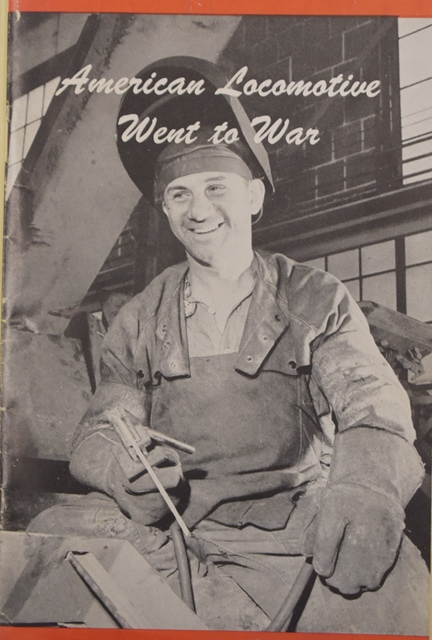

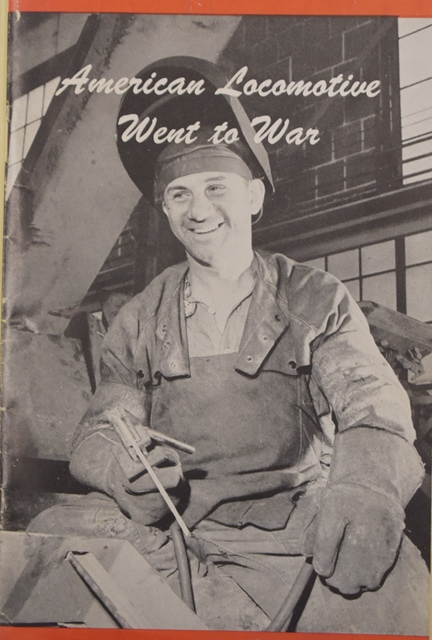

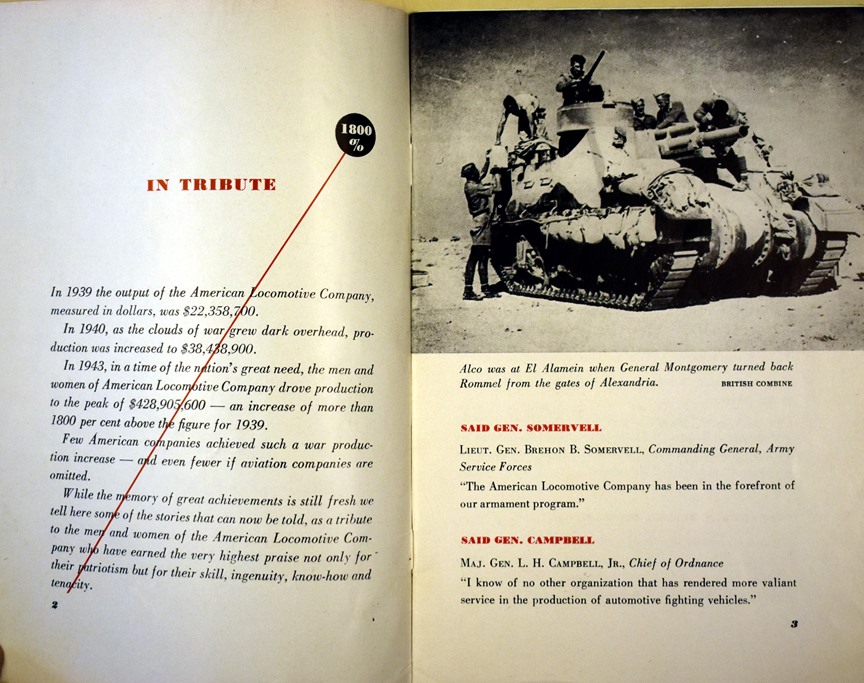

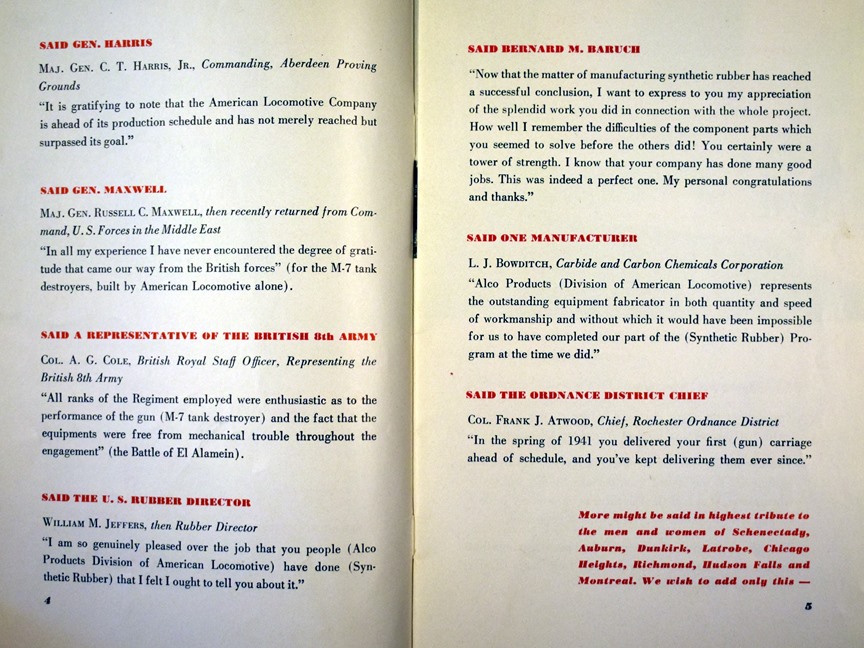

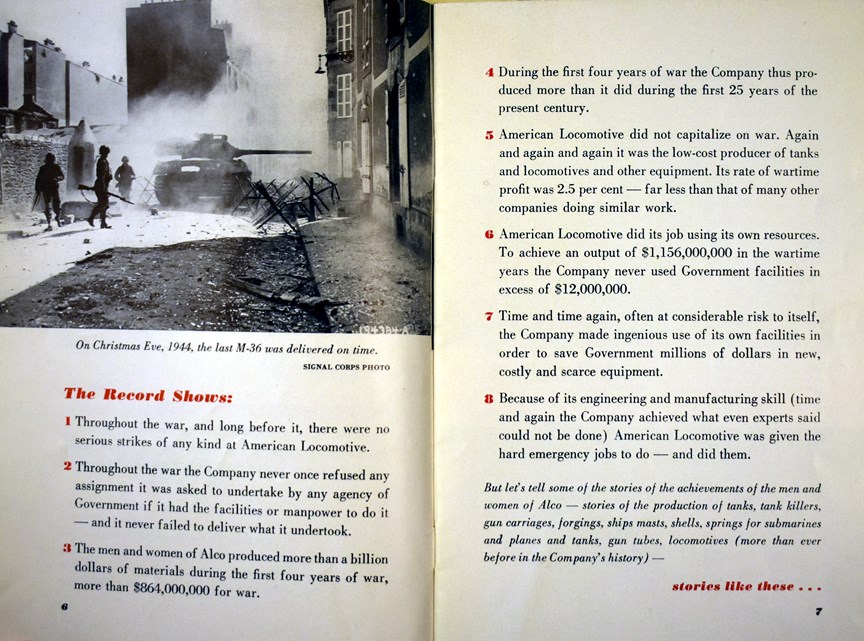

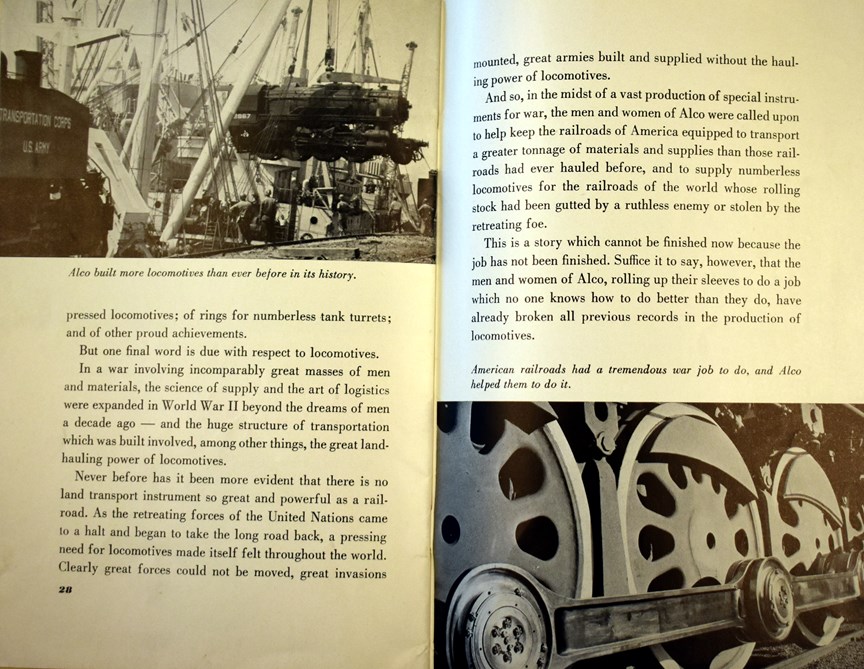

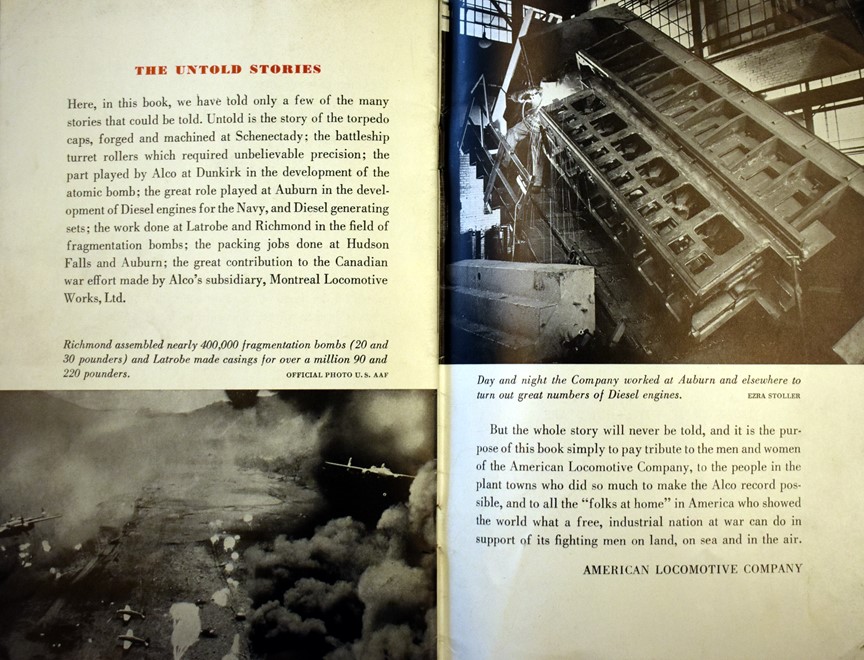

"American Locomotive Went

to War"

This post-war booklet is one of

the best I have seen that was produced by a company after World War Two.

While American Locomotive is most well-known for the armored vehicles it

produced, this booklet tells how many other products it produced that

were needed to win the war. I want to thank David and Denise Doyle

for photographing this, and then providing me with a copy.

|

-fortbenning-2018-107w-1.jpg)

-fortbenning-2018-107w-2.jpg)

-fortbenning-2018-107w-2.jpg)

-fortbenning-2018-107w-1.jpg)

-crestviewfl-sn1765-2022-107w-1.jpg)

-crestviewfl-sn1765-2022-107w-2.jpg)

-crestviewfl-sn1765-2022-107w-3.jpg)

-natlinfantrymuseum-sn25054-2018-107w-1.jpg)

-natlinfantrymuseum-sn25054-2018-107w-2.jpg)