|

Magnavox During World War Two

Fort Wayne, IN

1911-1975 Consumer Electronics

1911-1995 Military Electronics

This

page updated 4-6-2022.

The tall stove tube device on display at Robert's Armory in Rochelle, IL

is an M9A1 2.36 inch rocket launcher. It is most commonly known as

a bazooka and was designed as a man-portable anti-tank weapon.

This weapon may seem unrelated to an electronics company that was known

for its radios before World War Two and its television sets after the

war. However, the M9A1 and the earlier M9 bazookas came equipped

with Magnavox T6 magneto firing mechanism. Author's photo.

The Magnavox T6 magneto firing system was located in the operator's

handle. Author's photo.

This M9A1 is on display at the USAF Armament

Museum. Author's photo added 4-6-2022.

This photo gives another good view of the

Magnavox T6 magneto firing system. Author's photo added 4-6-2022.

The earlier M1/M1A1 bazooka used a battery

to ignite the rocket that the weapon fired. Problems arose almost

immediately with the early bazookas when they were introduced into

combat in North Africa in 1943. The batteries, if they were

available, were not popular because they were subject to discharge and corrosion in wet weather. The Magnavox T6 magneto firing system was more

dependable and not reliant on batteries.

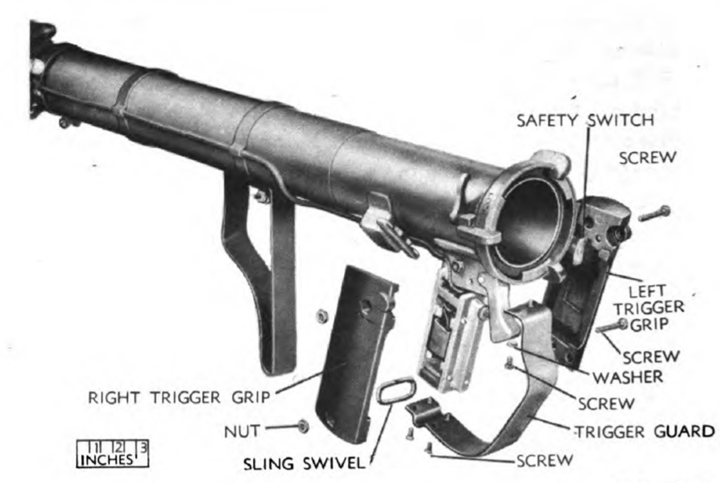

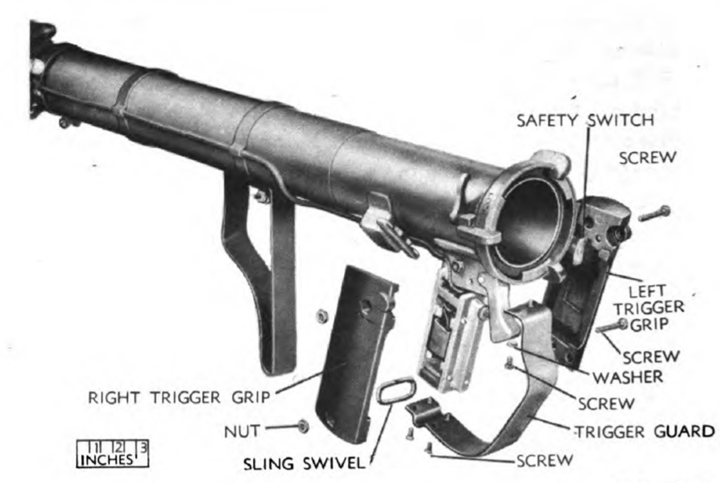

This is an exploded view of the firing

mechanism. Image from TM9-294.

The information below is a quote from

TM9-294:

"The firing mechanism is housed within the

trigger grips and is secured to the trigger grip support on the under

side of the rear barrel. It consists of a magneto, trigger, and

safety mechanism. The magneto consists of several magnets housing

a coil of wire which in turn houses a steel armature. When the

trigger is squeezed, the armature moves in the coil and generates

sufficient current to ignite the rocket. The safety switch is

located in the rear side of the left grip. When the safety switch

is manually moved to the "SAFE" position, the coil is shorted out of the

electric system so the no current reaches the rocket. The magneto

generates current when the trigger is squeeze and also when it is

released."

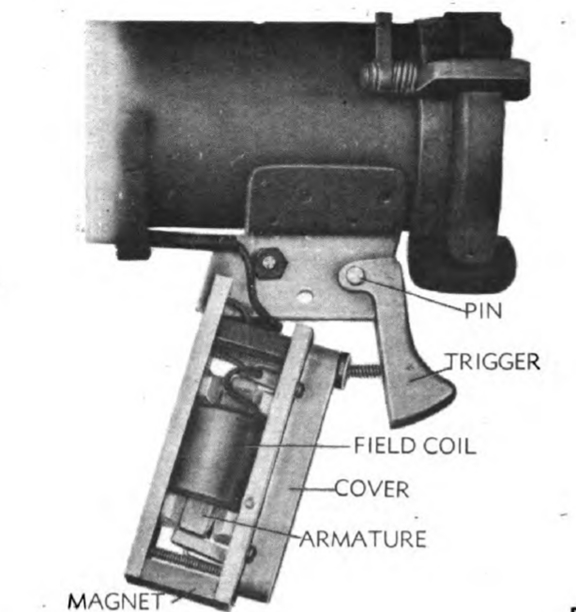

This is the left-hand view of the unit.

Image from TM9-294.

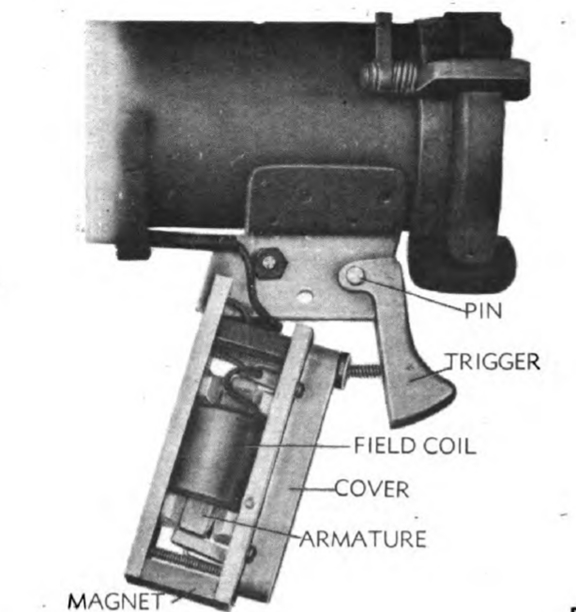

The right-hand view shows the trigger, field coil, armature, and

magnet. Pulling the trigger creates a current in the field coil as

the armature moves through it. The current flows to the rear of

the weapon where it ignites the rocket in the tube. Image from

TM9-294.

This M9A1 is on display at the National

Museum of the United States Army in Belvoir, VA. Author's photo.

The approach of a German Panzer V Panther

Ausf. A could spoil an American infantryman's whole day! However,

if he had a bazooka with a Magnavox firing mechanism that fired reliably

every time, he had a weapon that helped to even

up the odds against the 49-ton tank. Author's photo taken at the

American Heritage Museum.

The infantryman with a bazooka would work

his way around to the side or rear of the tank, as the 2.36 inch rocket

would not penetrate the front armor of the Panther. The

infantryman would aim for more vulnerable parts of the tank like

the tracks and wheels, the area between the tank body and its turret, or

the engine. Author's photo taken at the American Heritage Museum.

This M9A1 bazooka, equipped with a Magnavox T6

firing mechanism, is on display at the Camp Blanding Museum in Florida.

Author's photo.

Magnavox was started in 1913 in Napa, CA as

the Commercial Wireless and Development Company. In 1915 the

company invented the loudspeaker which was named Magnavox.

Magnavox is Latin for great voice. A year later in 1916, it

invented the first record player tone arm and automatic pickup. In

1917 the Commercial Wireless and Development Company merged with the

Sonora Phonograph Distributor Company and became the Magnavox Company.

After a relocation to San Francisco and then Oakland, the company moved

to Fort Wayne, IN to be located nearer to its main markets and to be close

to the magnet wire companies in the area. Magnet wire was a large

part of the construction of a loudspeaker.

After World War Two, Magnavox purchased a

cabinet plant in Greenville, TN. Then several years later,

Magnavox built a

plant to manufacture television sets in the same town. In 1960 it

built a second plant in Greenville, TN, which was the world's largest

plant for manufacturing television sets. Like other

American consumer electronics companies, it began to lose market share

to foreign imports. In 1975 it became a wholly owned subsidiary of

North American Phillips Development Company. While the name would

still be used as a brand name in consumer electronics through the early

1990s, Magnavox as an individual company was gone.

Magnavox Electronics Systems, which specialized in military products,

continued operations as an individual company headquartered along I-69 on the south side of Fort

Wayne until it was purchased by Hughes

Electronics in 1995. So ended the last independent Magnavox

company that began in 1911.

Magnavox World War Two Products:

Machine gun solenoid triggers controls, head set assemblies, antenna

reels, loudspeakers, microphones, amplifiers, radios, power supplies,

interphones, capacitors, noise filters, phone amplifier kits, telephone

installation kits, remote control kits, bomb arming controls, aircraft

components, film projectors, gun components, sound equipment, SCR-291

radio direction finders, and 257,776 T6 electric trigger controls for

the M6/M9A1 2.36 inch rocket launcher described above.

The next two photos show the reproduction of

the radio shack in the USS Indianapolis that is on display at the

Indiana War Memorial Museum in downtown Indianapolis. The photos

depict all of the various receivers in the USS Indianapolis. Author's

photo.

With the exception of three receivers, the

remaining radios were all built by RCA. RCA was the main provider

of radio receivers used on U.S. Navy ships in World War Two. Author's

photo.

One of the non-RCA radios on display is this

Magnavox-built Type CMX-46155-A long band receiver with frequency range

of 15 to 600 kilohertz. The CMZ-46155 with the associated

CMX-20131 power supply, also built by Magnavox, was denoted as the RAK-8, which was an RCA design.

Due to production constraints at RCA, Magnavox was chosen to build the

RAK-8 radio. Author's photo.

This RAK-8 is serial number 649. The highest

serial number I have found is another RAK-8 with the serial number 2318, indicating Magnavox

built at least that many. Author's photo.

Magnavox made an unknown number of SCR-291

aircraft direction finders, which consisted of a BC-1147 receiver

and associated equipment.

There was a total of 1,043 units built by all manufacturers between

1943 and 1945.

The Magnavox Fort Wayne Plant:

When the company moved to Fort Wayne in 1931, it built a plant located on

what was then named Bueter Road on the industrial east side of the city.

Since that time, the name of Bueter Road has been changed to Coliseum

Boulevard. Also, the former Magnavox plant in this location no

longer exists and the land has been repurposed with a new, modern

structure.

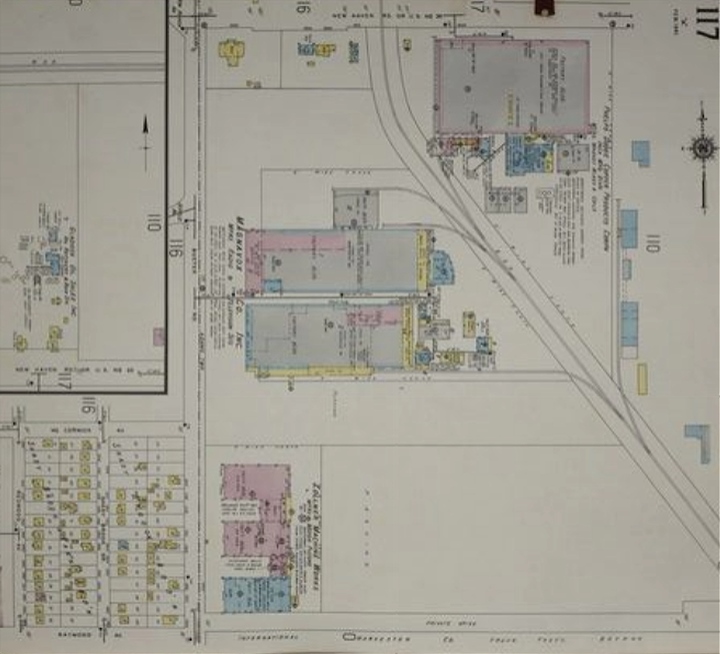

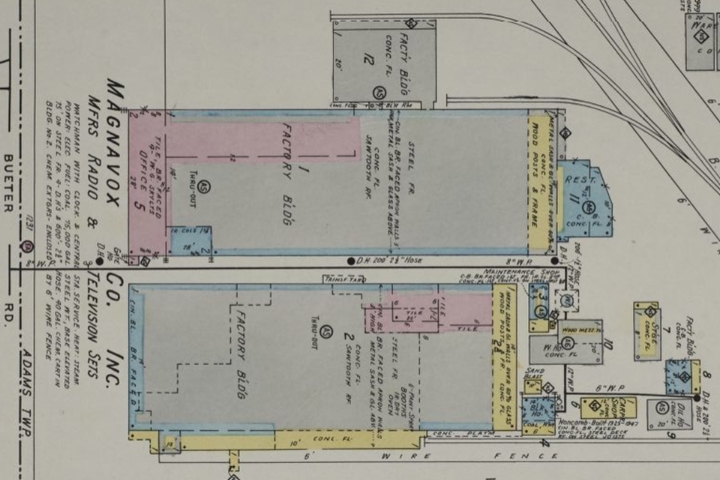

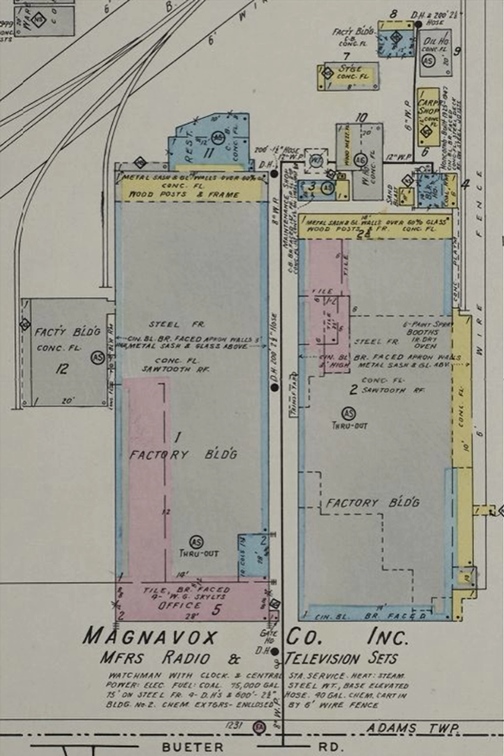

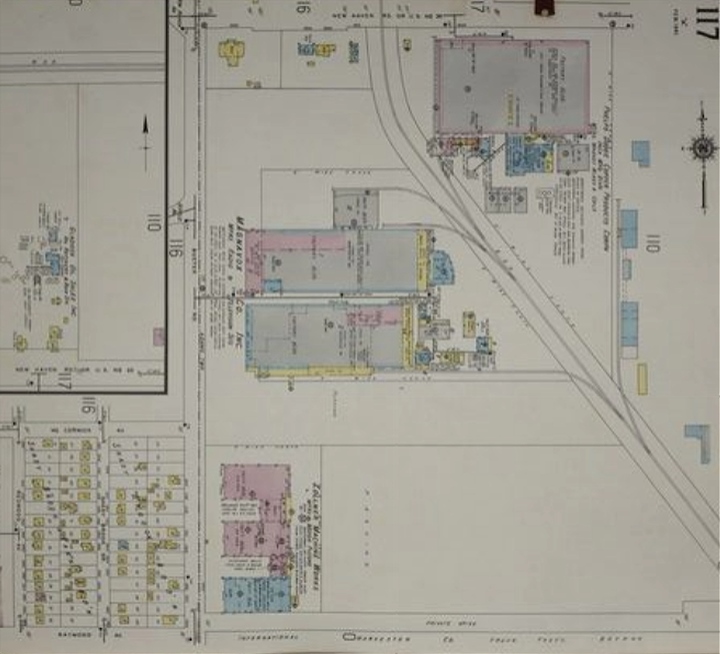

This 1951 Sanborn map shows the Magnavox

plant in the middle of the map. The Phelps Dodge magnet wire plant

was to the northeast, across the

railroad tracks. At the

bottom of the map, it notes the location of the north side of the large

International Harvester truck plant. The Studebaker plant that

made parts for R-1830 radial aircraft engines used on B-17 bombers was not shown on the map because

it was outside the Fort Wayne city limits.

It was directly to the east of Magnavox across the railroad tracks and

still exists today. Also not shown in this section of the map was the location of the

Farnsworth Television and Radio Corporation Plant to the southwest on

Pontiac Street.

One of the reasons Magnavox moved to

Fort Wayne was to be near the several magnet wire manufacturers in the

city. It couldn't have chosen a better location which put it right

next door to Phelps-Dodge, which was one of three magnet wire companies

in Fort Wayne. There was also Essex and Rea. The Phelps

Dodge plant is now the headquarters for Rea Magnet Wire.

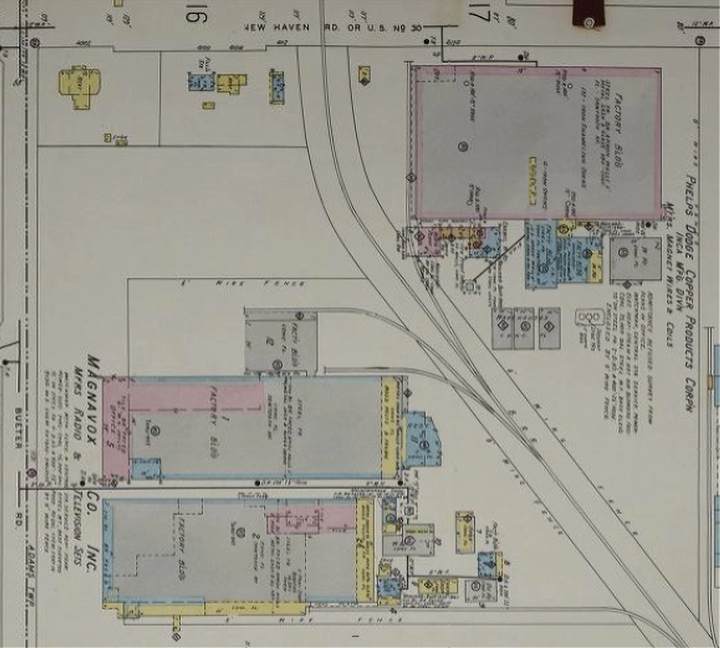

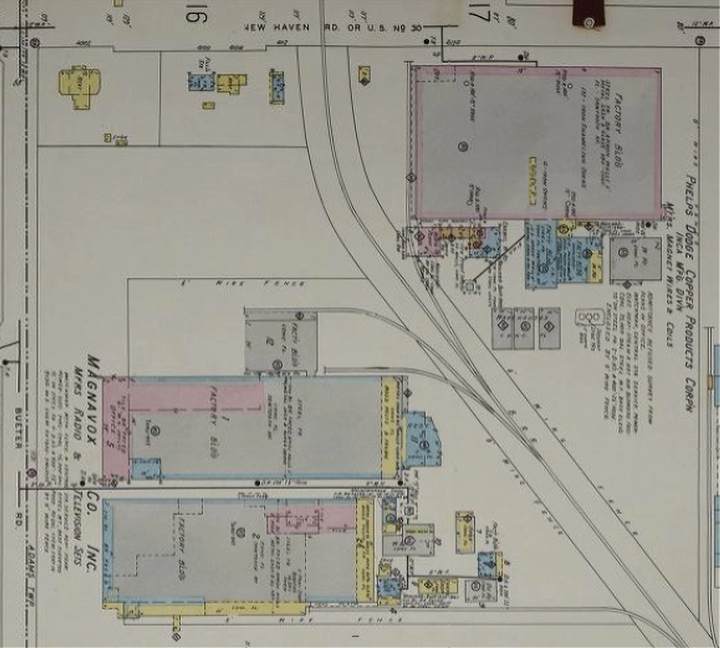

This image shows Magnavox and Phelps Dodge.

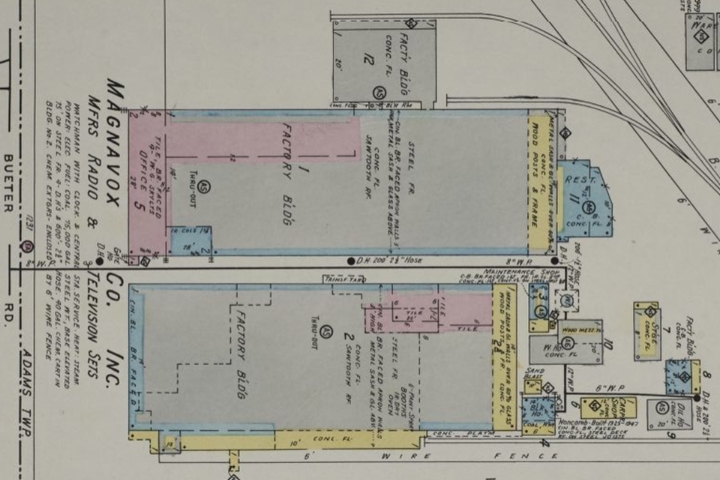

This image shows Magnavox.

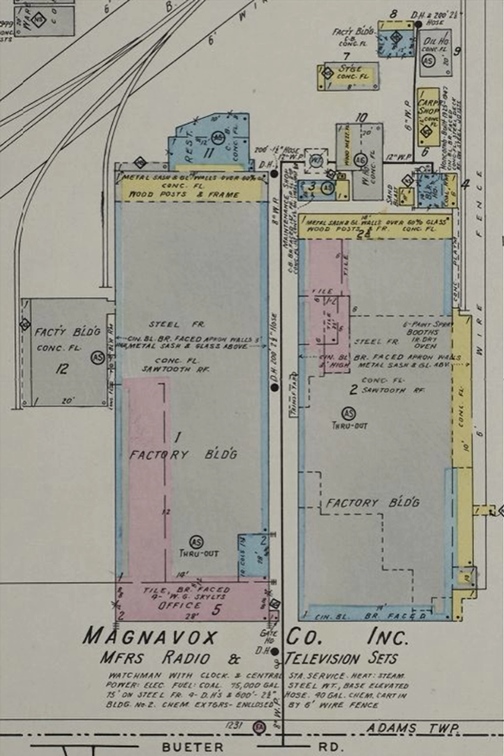

This turns the map 90 degrees.

Magnavox had two buildings at this location.

|