|

Other

Lansing Companies that contributed to winning World War Two

Motor

Wheel Corporation in World War Two

Recognizing a Company

from my Hometown that contributed to winning World War Two

1920-1996 Lansing, MI

Goodyear purchased in 1964

1984-Current as Motor Wheel in Chattanooga, TN

This page updated

11-6-2023.

The Motor Wheel Mark of

Quality sign above came from the former Motor Wheel cafeteria. It

is now at the R.E. Olds Transportation Museum in Lansing, MI.

Motor Wheel was formed in

1920 through the merger of five different companies. These were Prudden Wheel, Gier

Pressed Steel Company, Auto Wheel Company, and Wies & Leah Manufacturing

Company. Between 1920 and 1942, Motor Wheel produced 87 million

wheels for the American Automobile Industry. These were enough

wheels to equip 17,000,000 vehicles with five wheels each. During this

period, Motor Wheel was the world's largest producer of automotive

wheels and had one third of the American market.

In 1932, Motor Wheel began

producing brake drums using the newly developed centrifugal casting

method developed by the Campbell, Wyant, and Cannon Foundry in Muskegon,

MI. Motor Wheel was the exclusive user of the brake drums produced

by the new casting method. In 1937 Motor Wheel built a

foundry near its plants on the north side of Lansing and leased the

facility to the Campbell, Wyant, and Cannon Foundry, which changed its

name to Centrifugal Fusing. Between 1932 and 1948, Motor Wheel

produced 48,000,000 brake drums using the centrifugal casting method.

After World War Two Motor Wheel purchased Centrifugal Fusing. In

1964 Goodyear purchased Motor Wheel.

The company still exists

today in Chattanooga, TN and produces heavy duty brake drums with the

centrifugal casting method. In 1984, the brake drum operation of

Motor Wheel Corporation moved to Chattanooga, TN. In 1996 the

remaining wheel making operations in Lansing, MI closed down. The

Motor Wheel name currently continues today and produces heavy duty brake drums with

the centrifugal casting method.

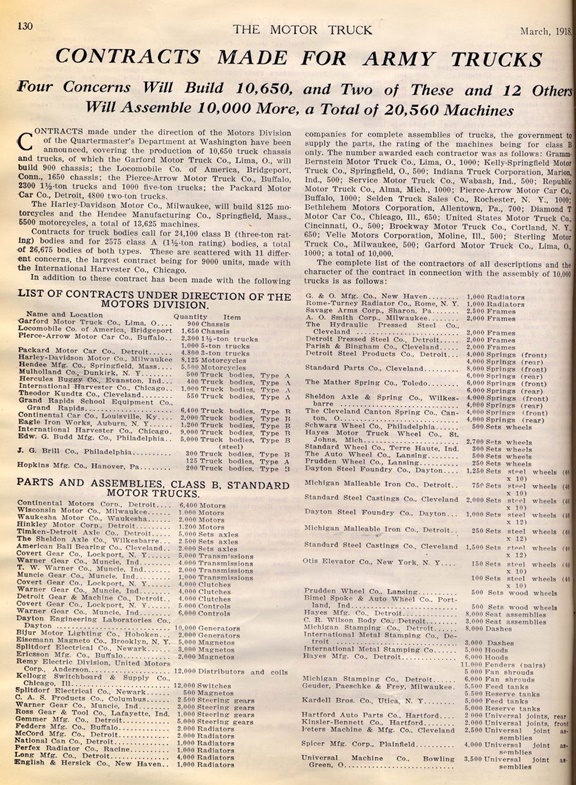

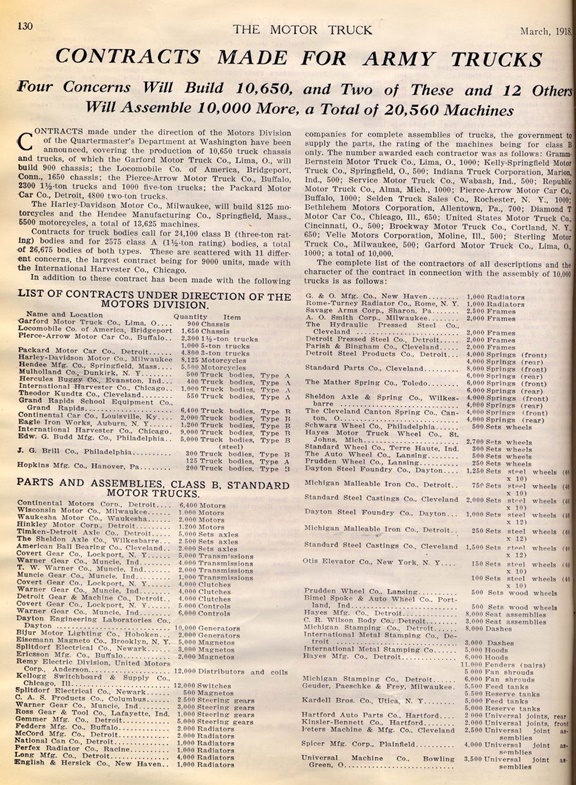

During World War One, Auto Wheel

Company

was contracted to produce 500 sets of wheels for the Class B, Standard Motor Truck,

more commonly known as the Liberty Truck.

The Prudden Wheel Company was contracted to produce another 250 sets of

wheels and 500 sets of wooden wheels for that vehicle. In 1919 the

two companies would merge with two other companies to become the Motor

Wheel Corporation. Document

courtesy of Warren Richardson.

This World War One Class B Liberty Truck has

been restored to operating condition by the First Division Museum in

Wheaton, IL. Author's photo.

This and the next two photos are a collection

of wheels produced by Motor Wheel that are on display at the R.E. Olds

Transportation Museum. The collection shows a wide

variety of wheels that the company produced while in Lansing.

Originally, Motor Wheel manufactured wooden wheels before the technology

for metal wheels was developed. Author's photo.

Author's photo.

Author's photo.

From almost the start of this website in 2013,

Motor Wheel was on my list of companies for which I wanted to do a page.

However, I was not able to find very much information on what the

company produced during World War Two. There was not enough

information to

author what I thought was needed to present an adequate history of the

company during this important period in the nation's history. In

early July 2021, I was able to discover slightly more information on

Motor Wheel in World War Two. The additional

information was enough to do a page on the company, but it would still

not have the depth of information I was really seeking to tell the true

and entire story of Motor Wheel during World War Two. This would

all change in early September 2021 as I visited Lansing, MI, and one of

my stops was the R.E. Olds Transportation Museum.

My primary purpose for visiting the Olds

Museum was to photograph the actual building, as I had discovered it was

the same building that the Hill Diesel Company occupied during its

existence in Lansing. The classic "being in the right place at the

right time" would allow me to find enough information to write this

page. While taking this photo, I noticed a museum employee exiting

the museum archives. In previous trips I had not even noticed the

entrance to the archives. I asked the employee if he was the

archivist, to which he answered "Yes." I then asked him if the

archives had any information on the history of Motor Wheel in World War

Two, to which he replied in the affirmative, and told me to follow him

into the archive area.

The R.E. Olds Transportation Museum had just

recently acquired a complete set of the "Motor Wheel News," the

company's employee newsletter for the years 1940-1945. The

newsletters had enough information on Motor Wheel's World War Two

products to allow me to now produce a page on the company and its

contribution to winning World War Two. All by being at the

right place at the right time.

Since I started this website in 2013, I have

looked at several company newsletters from World War Two.

Normally, only about 1% of the content of these newsletters address the

information I am seeking. Also, due to wartime censorship

restrictions, production numbers were not allowed to be published by

companies during the war, as

enemy agents could use it to determine the war production capacity of the country.

Also, in the particular case of the "Motor Wheel News," many of the

articles about its war products were somewhat vague. But I think I have been able

to find enough information to tell how the Motor Wheel Corporation was

an important manufacturer of products that helped win World War Two.

I want to thank Mr. Rick Kaiser, Operations

Manager for the R.E. Olds Transportation Museum, for spending over an

hour with me in researching Motor Wheel and several other Lansing

companies during my visit to the museum in September 2021. I

highly recommend this museum to anyone visiting Lansing, MI. This

is a first class museum.

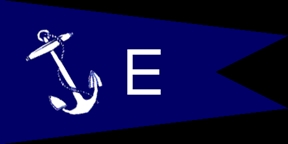

Motor Wheel Corporation won the Army-Navy "E"

Award five times during World War Two.

On March 9, 1942 the U.S. Navy congratulated

Motor Wheel for its production of one million 40mm shell casings.

The U.S. Navy had only expected Motor Wheel to complete half of that

amount by that date. For this, Motor Wheel was awarded the

Navy "E" Award on June 9, 1942.

On August 15, 1942 Motor Wheel replaced its

Navy "E" flag with the Army-Navy "E" flag as companies were allowed to

do.

Motor Wheel Corporation won its second Army-Navy "E" Award on November

15, 1942.

Motor Wheel Corporation won its third Army-Navy "E" Award on May 15,

1943.

Motor Wheel Corporation won its fourth Army-Navy "E" Award on December 10,

1943.

Motor Wheel Corporation won its fifth Army-Navy "E" Award on February 1,

1945.

Motor Wheel World War Two Production: Motor Wheel was

highly diversified in its products during World War Two. While the

company manufactured wheels for both trucks and tanks, it built many

other military products to help win World War Two. In 1941, Motor

Wheel received its first military contract for three-inch anti-aircraft

projectiles. By the end of November 1941, Motor Wheel was awarded

three other military contracts. One was from the Army for 400,000

75mm semi-armor piercing projectiles. The U.S. Navy also contracted the

company for three-inch anti-aircraft projectiles. This made

economic sense, as Motor Wheel was already producing this type of projectile for

the Army. Motor Wheel also contracted with the Navy for brass 40mm

shell casings for which it was already noted that it won the U.S. Navy

"E" award in June 1942. The company was also sub-contracting

other military products to

other manufacturers at this time.

These were the first of many contracts and a multitude of products Motor

Wheel would build during the war.

This docent on the destroyer escort USS

Slater is showing the tour group how a three-inch anti-aircraft

projectile would be loaded into one of the ship's three-inch dual

purpose guns. This photo shows the size of the type of shell Motor

Wheel was producing in late 1941. Author's photo.

This photo from the December 15, 1944 issue

of "Motor Wheel News" shows a long display table with components the

company was producing for the war effort. The related article

described the individual items. The next three paragraphs are a

direct quote from the "Motor Wheel News" that describe the contents of

the display. These three paragraphs are the most extensive listing

of Motor Wheel Corporation products made during World War Two.

"Supply truck wheels, combat wheels for "ducks," combat wheels for tank

destroyers, combat spiders, Centrifugal brake drums for fighters,

three-inch high explosive projectiles, 40mm gun casings, 75mm armor

piercing shot, implement discs, driver discs for M18 Hellcat tank

destroyers, idler wheels for M4 Sherman tanks, road wheels for Hellcats,

amphibian wheels for "alligators."

Bogie wheels and hubs for M4 Sherman tanks,

propeller domes for fighters and bombers, fuse seat liners, rockets and

motors, 40mm armor piercing cartridge cases, three-inch anti-aircraft

projectiles, three-inch 50 cal. H.V. projectiles, three-inch semi-armor

piercing projectiles, dolly wheels for trailers, torpedo fuel tanks,

hemisphere bomb noses, 57mm T4 containers, cylinder head covers, body

rim guards for aerial bombs, sleeve bearing retainers for "ducks."

Aeroplane brackets, Centrifugal brake drums

for Superfortresses and Flying Fortresses, spacers for amphibian "ducks,"

brake drums for trucks, spider plates for machine gun mounts, hubs for

155mm gun mounts, hubs and drums for 105mm gun mounts, tractor wheels."

This parade float shows what appears to be

armored vehicle road wheels and an idler wheel. Behind the wheels

are several types of shells. In the middle are several cylinders. The cylinders have rounded

tops welded to them and are for an unknown product.

For wheels and brake drums, production numbers

shown in the next section are for only OEM

production. Both products, especially brake drums, would have

needed a constant supply of spare parts. Brake drums throughout

the life of both trucks and aircraft would have been replaced many

times.

As I noted above, for many years I was unable

to find any information on Motor Wheel in World War Two until September

2021 when I gained access the Motor Wheel letters. In early 2022,

I became aware of available information on major war contracts issued by

U.S. Government agencies during World War Two. In the case of

Motor Wheel, these were the U.S. Army and the U.S. Navy, and their

contracts are listed in the table below. The information in the

table supports the narrative and information from the newsletters and

adds dollar amounts and the dates of the contracts. Shells, shot,

cartridge cases, and rocket bodies were main types of products supplied

to the Army and Navy by Motor Wheel. The total of all of the

contracts was $87,320,000.

Motor Wheel Corporation's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. Table added 4-5-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

|

Shells - Army |

$71,000 |

7-1940 |

5-1941 |

|

Shells - Army |

$308,000 |

3-1941 |

8-1941 |

|

Forgings - Projectiles - Navy |

$6,320,000 |

6-1941 |

7-1942 |

|

Shells - Army |

$229,000 |

7-1941 |

10-1941 |

|

Cartridge Cases - Navy |

$6,889,000 |

9-1941 |

11-1942 |

|

Shells - Army |

$231,000 |

11-1941 |

1-1942 |

|

Shot - Army |

$1,291,000 |

11-1941 |

7-1942 |

|

Shells - Army |

$308,000 |

1-1942 |

7-1942 |

|

Material Ordnance - Navy |

$7,264,000 |

2-1942 |

7-1943 |

|

Shot - Army |

$958,000 |

2-1942 |

9-1943 |

|

Shells - Army |

$647,000 |

3-1942 |

1-1943 |

|

Shot - Army |

$604,000 |

5-1942 |

12-1942 |

| Ordnance

Equipment - Navy |

$10,927,000 |

6-1942 |

7-1944 |

|

Shell Machining HE3 - Army |

$2,888,000 |

6-1942 |

10-1944 |

|

Shells - Army |

$978,000 |

7-1942 |

6-1943 |

|

Shot - Army |

$4,883,000 |

9-1942 |

5-1944 |

|

Shot - Army |

$1,122,000 |

10-1942 |

3-1943 |

|

Shot - Army |

$1,122,000 |

10-1942 |

3-1943 |

|

Shells - Army |

$573,000 |

12-1942 |

1-1943 |

|

Cases Cartridge - Navy |

$9,920,000 |

3-1943 |

2-1944 |

|

Bomb Parts - Navy |

$1,290,000 |

4-1943 |

7-1944 |

|

Cartridge Cases - Navy |

$8,171,000 |

6-1943 |

9-1944 |

|

Projectiles AA - Navy |

$2,417,000 |

8-1943 |

6-1944 |

|

Waterproof Gun Covers - Navy |

$280,000 |

9-1943 |

6-1944 |

|

Dummy Nose Plugs - Navy |

$57,000 |

1-1944 |

8-1944 |

|

Rockets MK 10 - Navy |

$1,003,000 |

3-1944 |

3-1945 |

|

Metal Containers T4 - Army |

$354,000 |

3-1944 |

6-1944 |

|

Protecting Caps - Navy |

$366,000 |

5-1944 |

1-1945 |

|

Wheels Spacers - Army |

$3,829,000 |

5-1944 |

12-1945 |

|

Projectiles AA - Navy |

$1,740,000 |

6-1944 |

2-1945 |

|

Cart Cases 40mm MK 2 - Navy |

$6,488,000 |

8-1944 |

4-1945 |

|

Protecting Caps MK 3 - Navy |

$490,000 |

9-1944 |

1-1946 |

|

Rocket Bodies - Navy |

$628,000 |

9-1944 |

4-1945 |

|

Projectiles - AA MK 31 - Navy |

$1,234,000 |

11-1944 |

7-1945 |

|

Rocket Bodies - MK 10 - Navy |

$606,000 |

2-1945 |

1-1946 |

|

Rocket Bodies - MK 10 - Navy |

$513,000 |

4-1945 |

2-1946 |

|

Projectiles - Navy |

$65,000 |

7-1945 |

12-1945 |

|

Amm Protecting Caps - Navy |

$346,000 |

7-1945 |

6-1946 |

|

Total |

$87,320,000 |

|

|

Motor Vehicle Wheels: Motor Wheel

was the supplier for the wheels on the most produced and famous American

truck of World War Two, the GMC CCKW 2-1/2-ton 6x6 truck. It also

furnished the wheels for GMC DUKW and the Studebaker US6 2-1/2-ton 6x6

truck. It produced many of the road and idler wheels for the M4 Sherman tank

series and for the M18 Hellcat tank destroyer. It was the

exclusive supplier of road wheels, return wheels, and idler wheels for

the M26 Pershing tank. Motor Wheel was an important supplier of

these products for the war effort.

This is the classic GMC 2-1/2-ton 6x6 truck

and is the long wheelbase version CCKW-353. Author's photo.

For the United States,

World War Two was the first completely mechanized war. There were

tanks, jeeps, tanks, armored cars, tank destroyers, halftracks, and

trucks that were used by the U.S. military. They came in all sizes from the 1/4-ton

4x4 Jeep to the 10-ton wrecker. But there is one truck that

comes to a person's mind when thinking or thinking of a trucks from World

War Two, and it is the GMC 2-1/2-ton 6X6. It is the definitive

truck of World War Two!

A Notable Quote from "The Great Crusade" by General

Dwight D. Eisenhower: "Incidentally, four other pieces of

equipment that most senior officers came to regard as among the most

vital to our success in Africa and Europe were the bulldozer, the jeep,

the 2-1/2-ton truck, and the C-47 airplane."

For the United States Army in Africa and Europe, the 2-1/2-ton truck

General Eisenhower refers to is the GMC CCKW. The CCKW was

exclusively used by the Army as the Studebaker version went to Great

Britain and Russia, and the International Harvester version was also

sent overseas on Lend-Lease, or were used by the U.S. Marines and Navy.

The Motor Wheel Corporation part number for

the CCKW series 20x7 wheel was 82023.

GMC

World War Two Trucks Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| CCW-353 |

0 |

707 |

22,687 |

255 |

0 |

0 |

23,649 |

| CCKW-352 |

244 |

20,372 |

22,657 |

9,325 |

954 |

440 |

53,992 |

| CCKW-353 |

7,929 |

30,424 |

88,329 |

121,518 |

125,732 |

89,717 |

463,649 |

| AFKWX-353 |

0 |

0 |

613 |

1,619 |

4,000 |

1,000 |

7,232 |

|

Total |

8,173 |

51,503 |

134,286 |

132,717 |

130,686 |

91,157 |

548,522 |

Number of Motor Wheel Corporation Wheels made for the GMC

CCW, CCKW-352, CCKW-353, and AFKWX-353 Trucks

|

|

Type |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| CCW-353 - 11

Wheels per Truck |

0 |

7,777 |

249,557 |

2,805 |

0 |

0 |

260,139 |

| CCKW-352

- 12 Wheels per Truck |

2,928 |

244,464 |

271,884 |

111,900 |

11,448 |

5,280 |

647,904 |

| CCKW-353

- 11 Wheels per Truck |

87,219 |

334,664 |

971,619 |

1,336,698 |

1,383,052 |

986,887 |

5,100,139 |

| AFKWX-353

- 11 Wheels per Truck |

0 |

0 |

6,743 |

17,809 |

44,000 |

11,000 |

79,552 |

|

Total |

90,147 |

586,905 |

1,499,803 |

1,469,212 |

1,438,500 |

1,003,167 |

6,087,734 |

This GMC 1941-1942 CCW-353 6x4 is minus its outer back wheels.

Motor Wheel Corporation supplied 260,139 wheels for this type of truck. This particular

example has a 210 CFM Roi Air Compressor mounted on the bed.

Author's photo.

This steel enclosed cab CCKW-353 shows the

location of the spare tire underneath the body of the truck. This

was the supply version of the truck. Motor Wheel manufactured

5,100,139 wheels for the 463,649 long bed CCKW-353. Author's

photo.

The CCKW-352 was a short bed version of the

truck and was intended to be a prime mover of artillery. Due to the

lack of space underneath the short bed body, the spare tire and fuel

tank were moved between the cab and the body. This movement

allowed for a second spare tire to be placed in this area on the truck.

Therefore, Motor Wheel had to supply twelve wheels for this type of

vehicle. This amounted to 647,904 wheels. Author's photo.

GMC built 7,232

of the AFKWX-353, which was a cab over engine design with a longer cargo

body for transporting bulky loads. It had the same wheel base as

the CCKW-353 and had a 15 or 17 foot body which was three or five feet

longer than the CCKW-353 series truck. Like the CCW-353 and

CCKW-353, the AFKWX-353 had one spare tire underneath the body. It

required eleven tires per vehicle. Motor Wheel Corporation

supplied 79,552 wheels for the AFKWX-353 during World War Two.

Author's photo.

This is the Studebaker US6 2-1/2-ton 6x6

truck which was provided to foreign countries either through direct

purchase or Lend-Lease. In 1941, Motor Wheel supplied brake drums

and hubs for 5,714 US6 trucks destined for Great Britain when the normal

supplier could not furnish these parts. Author's photo.

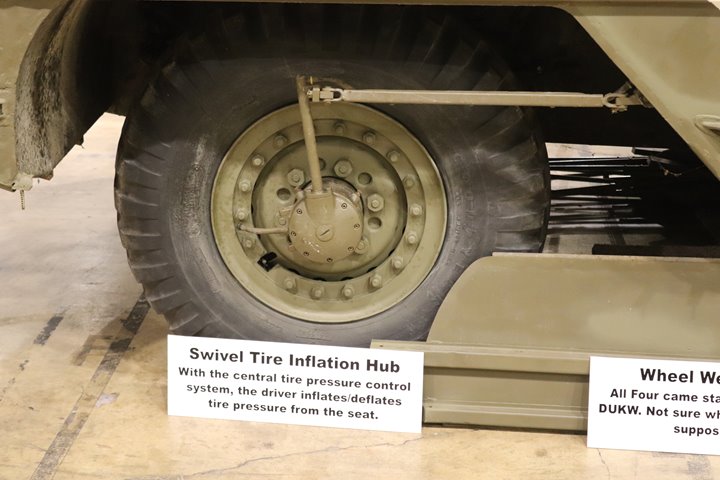

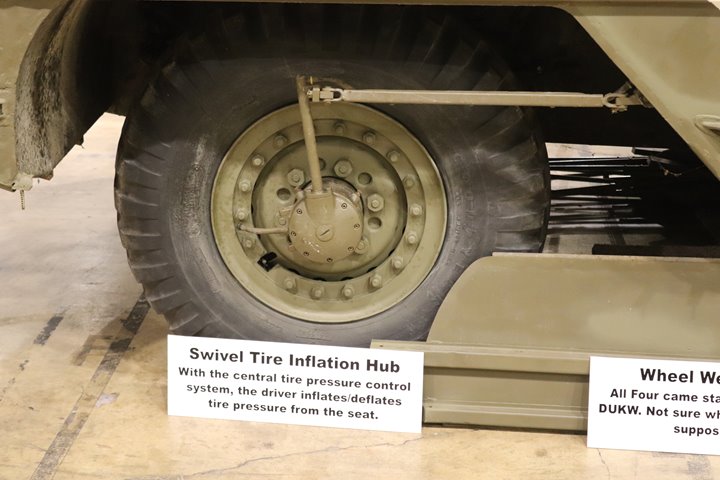

DUKW: The April 1, 1944, edition

of the "Motor Wheel News" notes that Motor Wheel Corporation supplied

the wheels for the GMC DUKW. The Ordnance Supply Manual shows that

prior to serial number 406, the disk and rim used a Goodyear "L" rim in

GM part number 2182022. For serial numbers starting with 406, a

wheel assembly used a Firestone "CV" rim with GM part number 2182087. It appears that Motor Wheel was a subcontractor to both

of

these companies, supplying wheel components to both Goodyear and

Firestone for use on the DUKW. There were 21,147 DUKWs built

during World War Two. Motor Wheel as a subcontractor supplied

124,882 wheels for this very important vehicle.

Author's photo added 12-25-2021.

Author's photo added 12-25-2021.

Gun Carriages:

The 155mm "Long Tom" is identified in the

"Motor Wheel News" as having wheels and hubs built by Motor Wheel on the

north side of Lansing, MI. There were 494 155mm cannons produced

during the war. Each carriage had ten wheels indicating Motor

Wheel would have provided 4,940 wheels and hubs for the weapon. Author's photo.

Motor Wheel Corporation supplied hubs and

brake drums for the 8,536 105mm howitzers built in World War Two.

Author's photo added 12-25-2021.

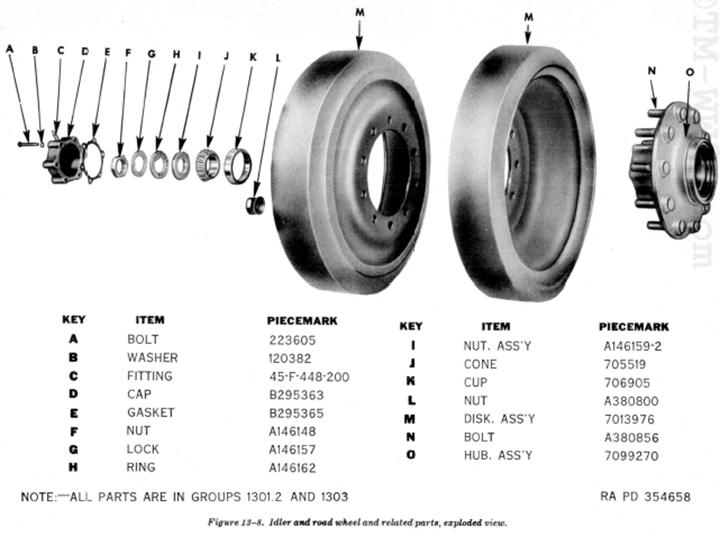

Road, Idler, and Track Return Wheels for Tracked Vehicles:

Author's Note: There were several

different names for the different types of wheels used on World War Two

tracked vehicles. Road wheels were also called boogie wheels.

Sometimes they were also described as disks. The track return

wheels were also described as rollers in some publications.

M4 Sherman Tank Road and Idler Wheels: Motor Wheel

made an undetermined amount of road wheels for the Sherman. There

were six types of road wheels manufactured for the Sherman tank with the Vertical Volute

Suspension System (VVSS). Motor Wheel is documented as

producing what was known as the stamped spoke type. There were

40,661 Sherman tanks produced with VVSS. There were another 13,942

gun motor carriages and other types of vehicles that were built on

Sherman chassis equipped with VVSS. Each vehicle had twelve road

wheels, resulting in at least 655,236 road wheels required for original

equipment. If Motor Wheel built 10% of the Sherman VVSS road wheels,

it would have produced over 65,000.

Motor Wheel was a subcontractor to the final

manufacturer for this product. After the basic metal wheel was

assembled, it needed to go to a rubber tire company which then

vulcanized a rubber tire around the outer diameter of the wheel.

The last step in the process was then installing the bearings in the

unit. Motor Wheel also produced the smaller idler wheel in the

stamped spoke design.

This M4A3(75)VVSS is equipped with stamped spoke road and idler wheels like Motor Wheel

built. Author's photo.

The photo shows the rubber tires were

vulcanized onto the wheel. Motor Wheel only built the basic wheel.

The final supplier of the road and idler wheels installed the bearings,

making them ready for installation onto the tank. A considerable

number of spares were needed for the road wheels, as debris that the tank

ran over in operation caused the rubber wheels to disintegrate during

use. Author's photo.

This example of an M4 Sherman tank with VVSS

shows the bare road wheels with no rubber tire. The road wheels

and idler wheel at the rear of the tank are the stamped spoke type that

Motor Wheel manufactured. With the rubber wheels off, this photo

shows the wheel as it came off the Motor Wheel assembly process, minus

the bearings. Author's photo.

The M36 tank destroyer was converted from

the earlier M10A1 tank destroyer. The three-inch main gun was

replaced with a more powerful 90mm main gun in a new larger turret.

The drive train to the M10A1 and similar M10 used the same Vertical

Volute Suspension System as the Sherman tank. This particular M36

has five of the six road wheels and the idler wheel with stamped spoke

wheels like Motor Wheel made. As the war progressed, it was not unusual to find several different types of road wheels on the Sherman

type vehicles. Damaged road wheels were replaced with whatever was

available, many of the wheels having been salvaged from destroyed

vehicles. Author's photo.

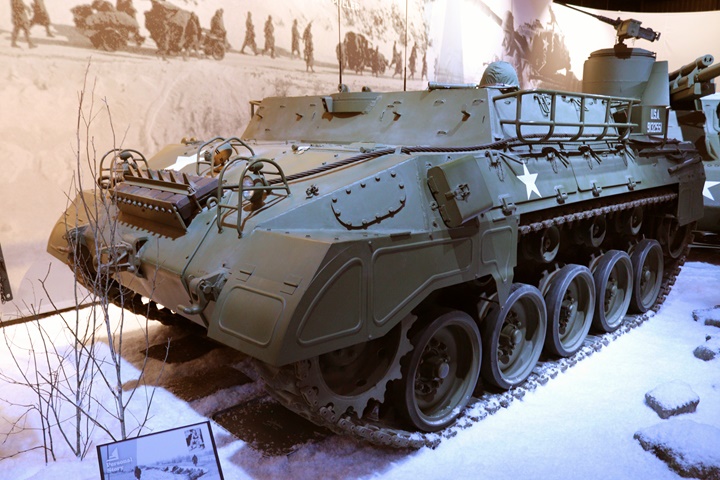

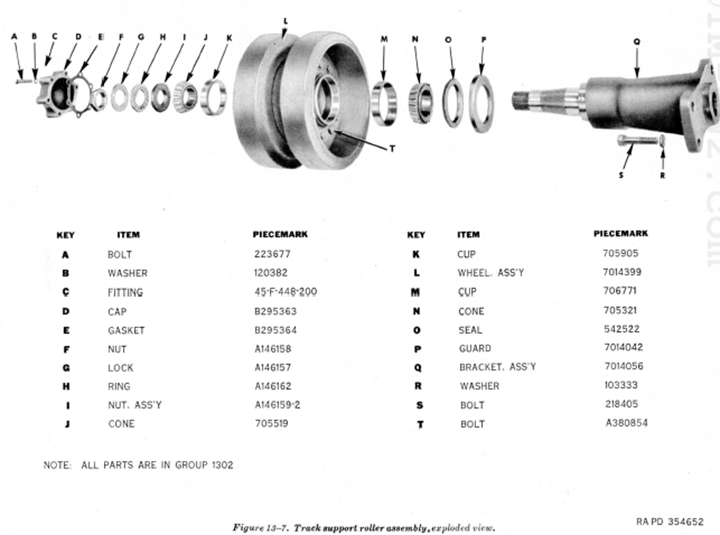

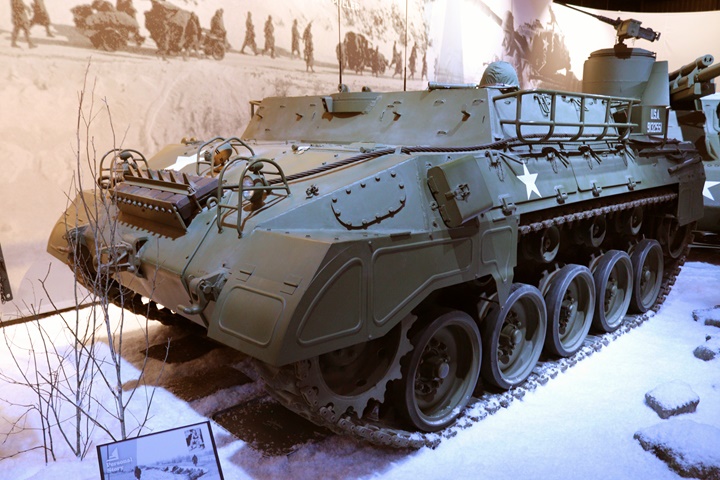

M18 Hellcat Tank Destroyer Road, Idler, and

Return Track Wheels: Motor Wheel was the supplier of the road,

idler, and return track wheels for this Buick-vehicle built in nearby

Flint, MI. There were 2,507 M18 tank destroyers built.

Buick-Built World War Two M18 Tank Destroyers Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946.

Included are the number of wheels and track rollers that Motor Wheel Corporation

manufactured for this vehicle. |

|

Type |

1943 |

1944 |

Total |

| M18 Tank

Destroyer |

812 |

1,695 |

2,507 |

|

Road Wheels - 20 per Vehicle |

16,240 |

33,900 |

50,140 |

| Idler

Wheels - 4 per Vehicle |

3,248 |

6,780 |

10,028 |

|

Return Track Rollers - 16 per

Vehicle |

12,992 |

27,120 |

40,112 |

This restored M18 Hellcat shows the Motor

Wheel-built road wheels, idler wheel, and return track rollers. Author's photo.

With the tracks off of this M18, it can

be seen that there are two road wheels per axle or twenty per vehicle.

There also two idler roller and track return wheels per axle. The

total number of track return rollers was sixteen per vehicle and four idler

wheels per vehicle. Motor Wheel Corporation manufactured the steel

wheel and then sent it on to another supplier to add the rubber tire. Author's photo.

Motor Wheel produced 50,140 M18 road wheels,

40,112 track return rollers, and 10,028 idler wheels during World War

Two. Both the road wheels and the return rollers needed to be sent to a rubber

company to vulcanize the rubber tire on. All three types of wheels

were then sent to the final supplier to add the bearings. Author's

photo.

Production of the M18 was discontinued in 1944 after a short two year

production run because the 76mm main gun was not able to penetrate the

armor of German Panther and Tiger tanks as expected. Because of

this, 640 M18s had their turrets removed and the interior of the vehicle

configured as a troop carrier. This new vehicle was designated as

the M39. The M39 continued to use the same Motor Wheel

Corporation-built wheels as the M18. Author's photo.

M26 Heavy Tank Road, Idler, and Return

Track Wheels: Motor Wheel had the exclusive contract for these

components.

|

Chrysler

and Fisher Body-Built

World War Two M26 and M45 Pershing Heavy Tanks Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946.

Included are the number of wheels and track rollers that Motor Wheel

Corporation manufactured for this vehicle. |

|

Type |

1944 |

1945 |

Total |

| M26 - Fisher

Body |

40 |

1,689 |

1,729 |

| M26 -

Chrysler |

|

473 |

473 |

| M45 -

Chrysler |

|

185 |

185 |

| Total |

40 |

2,347 |

2,387 |

| |

|

|

|

|

Road Wheels - 24 per Vehicle |

960 |

56,328 |

57,288 |

| Idler

Wheels - 4 per Vehicle |

160 |

9,388 |

9,548 |

|

Return Track Rollers - 20 per

Vehicle |

800 |

26,940 |

27,740 |

This is a Fisher Body-built M26 Pershing with Motor

Wheel Corporation-produced road wheels, idler wheels, and return track

rollers. Motor Wheel shipped the road wheels to the Kelsey-Hayes

Company which was responsible for adding the rubber tire and the

installation of the bearings and hub assembly. Author's photo.

This un-restored M26 shows two Motor

Wheel-produced road wheels without the rubber tire. Author's

photo.

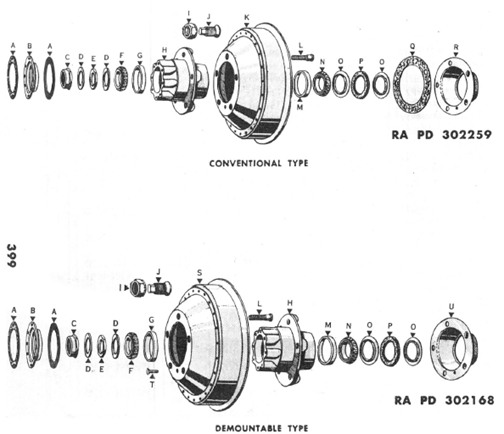

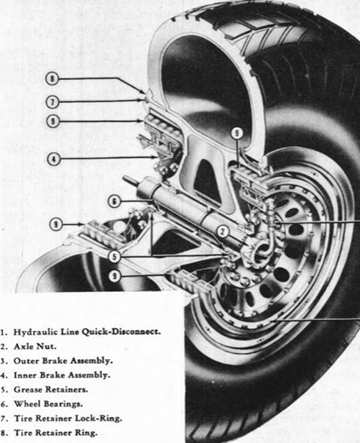

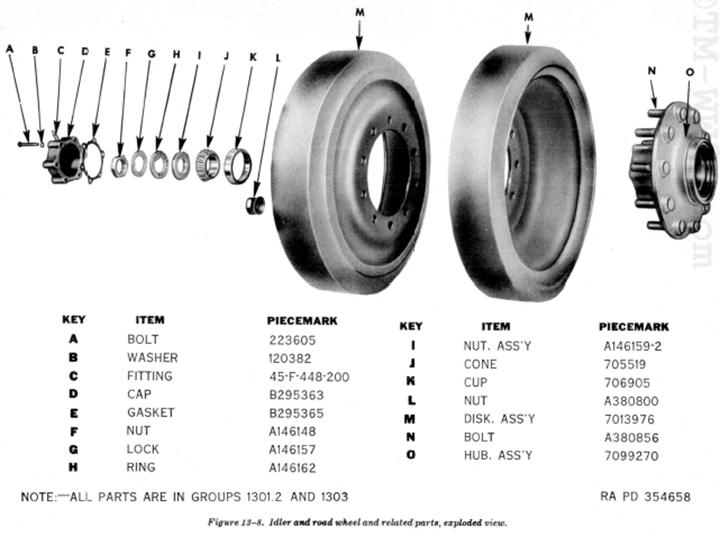

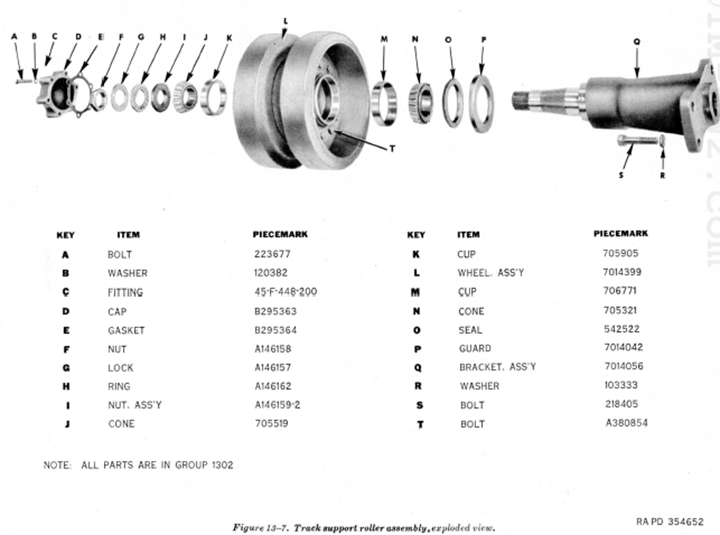

This image shows the final assembly of two

Motor Wheel wheels, or disks as described by the U.S. Army, into the

final assembly which was completed by Kelsey-Hayes.

This image details the track support roller

assembly with two Motor Wheel rollers.

Landing, Vehicle, Tracked Road Wheels (LVT):

The Motor Wheel Corporation produced an undetermined number of road

wheels for the LVT series of tracked landing craft. The "Motor

Wheel News" only has one reference that the company was producing

boogie, or road wheels, for the LVTs. The article has two photos

that show two different types of LVTs. One was the type LVT

which had the prime contractor as the Food Machinery Corporation.

The Reo Motor Company in Lansing was producing boogie wheel assemblies

in its nearby plant on the south side of Lansing. Motor Wheel

could have been a supplier to Reo for the wheels.

This is an LVT-4 for which the Food

Machinery Corporation was the prime contractor. Author's photo.

This photo shows the boogie wheels for the

LVT-4. Author's photo.

The LVT-3 was developed and built by the

Ingersoll Steel and Disc Division of Borg Warner in Kalamazoo, MI. One of the photos in the "Motor Wheel

News" article on the LVTs shows an LVT-3 landing at Okinawa in

1945. The historical record is unclear for which type of LVT Motor Wheel was

making boogie wheels. Author's photo.

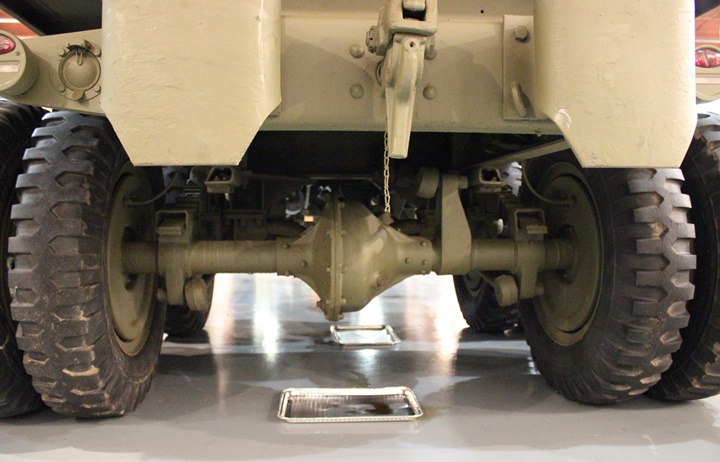

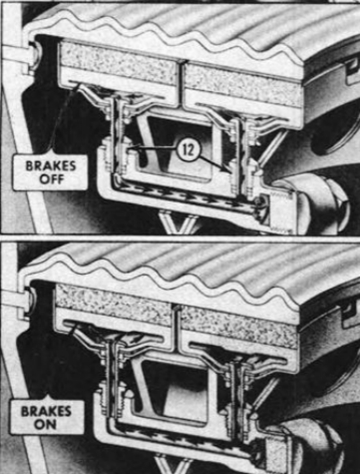

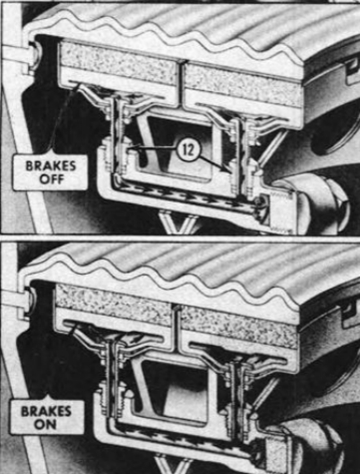

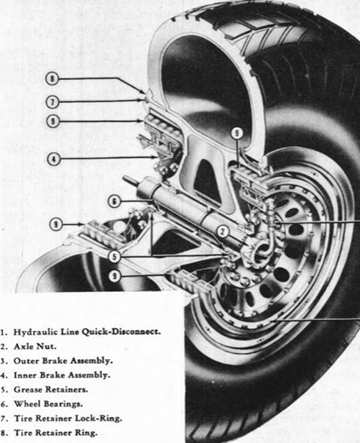

Motor Vehicle and Aircraft Brake Drums:

Motor Wheel Corporation produced the rear brake drums and hub

assemblies for the GMC CCKW truck series. It also produced brake drums

for the B-17, B-24, B-29, and P-47 aircraft. All Motor Wheel

brake drums utilized castings furnished by Centrifugal Fusing of

Lansing, MI.

Motor Wheel was one of two suppliers that

supplied brake drums for the GMC CCKW series of trucks. It all

depended upon which type of axle was used in the vehicle.

Timken-Detroit Axle Company was the primary supplier of axles for the

CCKW. These were known as split axles due to the type of

differential it used. Motor Wheel supplied the rear brake drums

and hub assemblies for this type of rear axle. Timken-Detroit supplied the

front drums on these type of axles. However, the Timken-Detroit Axle

Company was not able to supply all of the axles required. Chevrolet also

supplied axles for the CCKW series trucks. These were known as

banjo axles, again due to the type of differential manufactured by

Chevrolet. These axles did not use Motor Wheel brake drums.

An estimated 50% of the CCKW series trucks

were assembled with Timken-Detroit axles. Motor Wheel Corporation

supplied an estimated 1,097,044 rear brake drums and hub

assemblies for the vehicle.

This is a pristine GMC CCKW-353 airborne

cargo-dump. All airborne cargo-dumps were equipped with Timken-Detroit split axles and Motor Wheel brake drums.

Author's photo

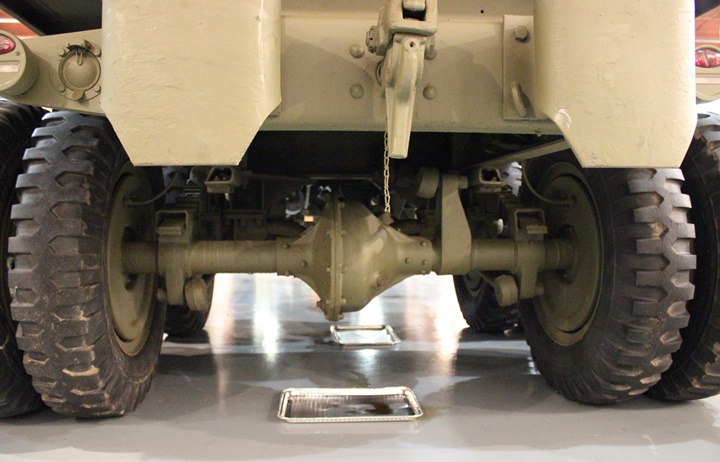

The Timken-Detroit split differential axle

with Motor Wheel brake drums.

Author's photo.

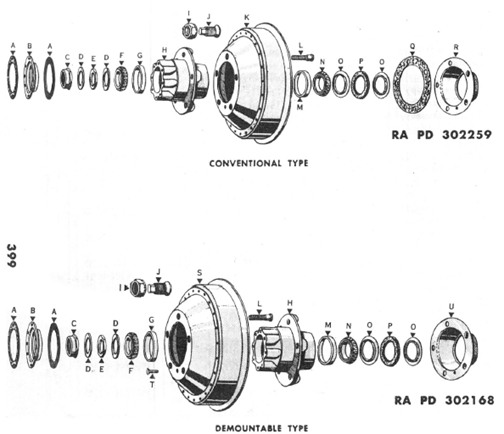

The Motor Wheel part number for the rear

conventional brake drum was 80026A. The part number for the

demountable type was 82517A.

|

Motor Wheel CCKW Truck Series

Rear Split Axle Part Numbers |

|

Part Type |

Part Number |

| Rear

conventional brake drum |

80026A |

|

Rear demountable brake drum |

82517A |

|

Rear conventional hub assembly with brake drum - left |

82004 |

|

Rear conventional hub assembly with brake drum -right |

82003 |

|

Rear demountable hub assembly with brake drum - left |

82514 |

|

Rear demountable hub assembly with brake drum - right |

82513 |

|

Rear conventional hub assembly |

82005 |

|

Rear demountable hub assembly |

82005 |

This October 1, 1943 "Motor Wheel News"

article shows truck axles being uncrated and then assembled into 6x6

trucks. These are GMC 2-1/2-ton CCKW trucks from the size of

the wheels and the split type of differential. The photos state that

not only were

the wheels built by Motor Wheel but also the hub and drum assemblies. What is

missing from the article is an exact identification of the vehicles. The newsletter editor may have found these photos

and used them as a generic example of the war products being

manufactured by the company. If so, he was lucky to have found

photos of GMC CCKW axles with split axles built by Timken-Detroit.

They could very well have been Chevrolet banjo type axles.

Maybe he knew the difference.

This is the B-17F Memphis Belle on May 17,

2018, 50 years to the date that she completed 25 combat missions over

Europe. This photo was taken several hours after the dedication of

the Memphis Belle at the National Museum of the United States Air Force.

The Memphis Belle, which is one of the most famous aircraft of World War

Two, came equipped with Motor Wheel brake drums. Author's photo.

The front page of the November 1, 1942 issue

of the Motor Wheel News had photo of three P-47s in flight. The

caption underneath the photo noted that the P-47s were equipped with

parts produced by Motor Wheel. Most likely the parts were brake

drums similar to the ones the company was building for the B-17.

Author's photo.

The drum would have fit in each of the

wheels of the main landing gear. Author's photo.

The "Motor Wheel News" notes that the

company made parts that were on the B-24. It has to be assumed

these were brake drums. The B-24 was the most widely produced

American heavy bomber of World War Two with 18,493 built. Author's

photo.

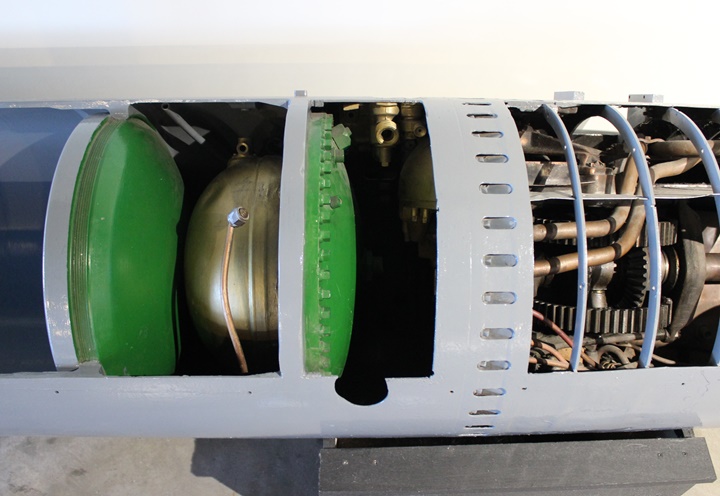

The B-29 Program: Motor Wheel was

the exclusive supplier of both the brake drums and propeller domes for

the B-29 Superfortress.

The B-29 Enola Gay was equipped with brake

drums and propeller dome built by the Motor Wheel Corporation in

Lansing, MI. Author's photo.

Author's photo.

This the B-29 Bockscar at the National

Museum of the United States Air Force in Dayton, OH. It is one of

3,763 B-29s were built by four different companies during World War Two.

Author's photo.

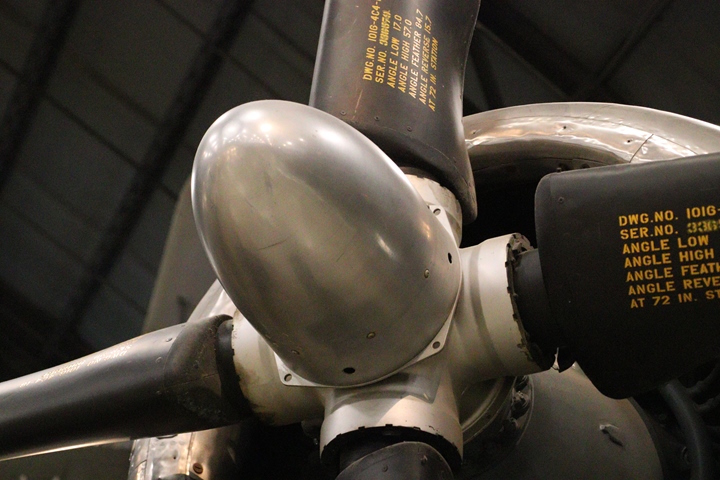

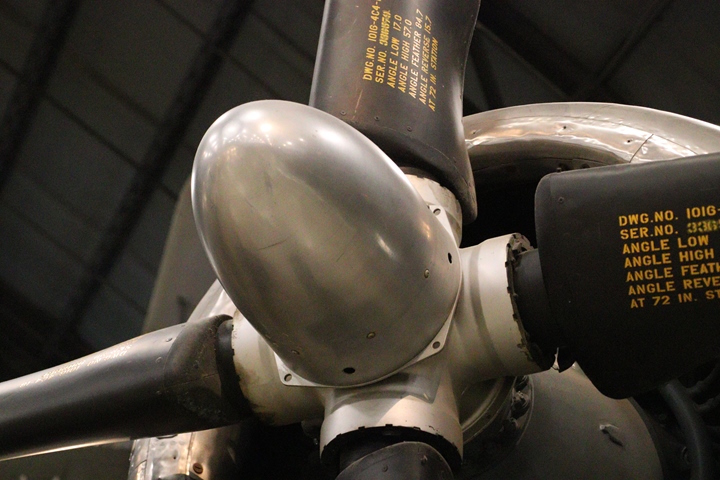

A close-up view of one of the Motor

Wheel-built propeller domes on Bockscar. Motor Wheel was the

exclusive manufacturer of the propeller domes as described in the November

1944

edition of Motor Wheel News and supplied at least 15,052 propeller domes

plus spare units for the war effort. Author's photo.

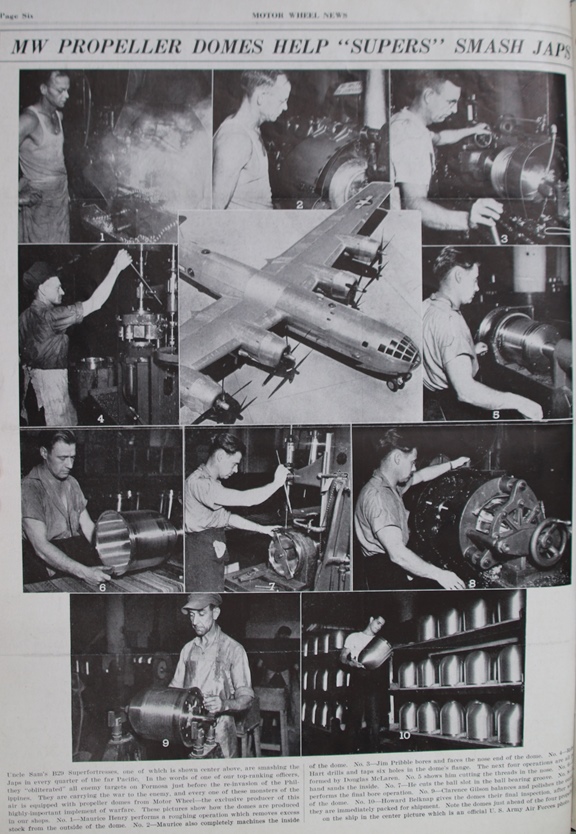

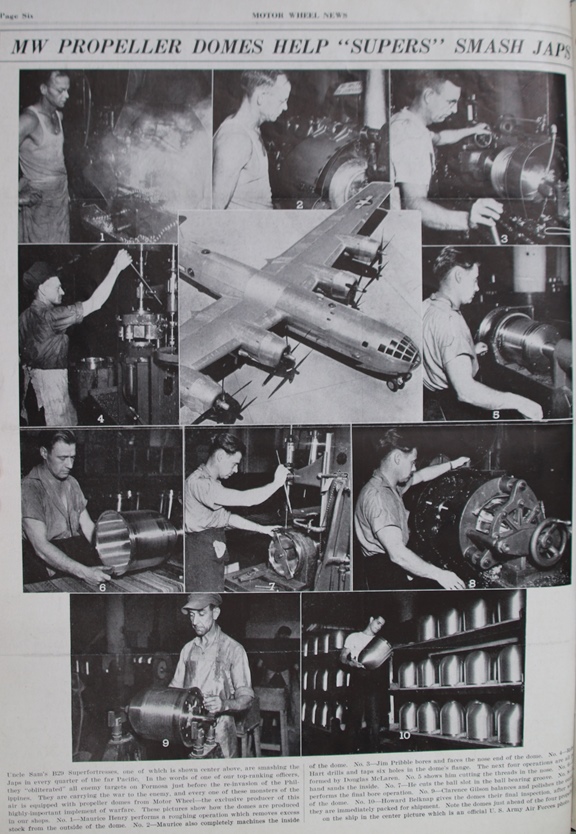

The above page from the Motor Wheel News

shows parts of the manufacturing process for the propeller domes.

Note that none of the workers were wearing safety glasses.

Motor Wheel also made brake drums for the B-29 bomber. This is the outside port wheel and tire for

Bockscar. The ridges on the outer diameter of the Motor Wheel brake drum can

actually be seen from the 12 o'clock to 2 o'clock position. The

drawings below show the ridges in more detail.

Author's photo.

Motor Wheel was most likely the exclusive supplier

for the B-29 brake drums. While this was not specifically

stated in any edition of the "Motor Wheel News," when the workers of its

casting supplier went on strike in 1945, brake production for the B-29

came to a halt. Based on this, Motor Wheel Corporation would have

produced a minimum of 30,104 plus brake drums plus spares. Each

B-29 had two sets of brakes on its four main wheels. Brake

drums on the B-29 were a high maintenance

item and there would need to be a constant flow of spare parts for

replacement. Motor Wheel was a sub-contractor to the company that

supplied the brake assembly for the aircraft.

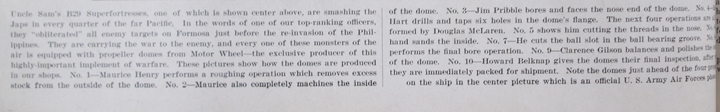

This image shows that the brake drums were actually made of two pieces.

It also shows the ridges in the outer diameter. The purpose for

the ridges may have been to give the brakes more surface area to assist

in their cooling.

This image shows the two sets of brakes on

the B-29 main landing gear.

Shells and Rockets: Motor Wheel

Corporation produced several types of projectiles, shell casings, and

rockets during World War Two.

The U.S. Navy awarded Motor Wheel

Corporation its first Army-Navy "E" award in June 1942 for the

production of one million 40mm shell casings, twice the amount the Navy

had expected in the same time period. Author's photo.

This is a 40mm shell casing with the Motor

Wheel insignia shown at the top of the photo. This was lot number

1001 dated October 1944. Photo courtesy of Superstar added

11-6-2023.

The "Motor Wheel News" indicates that the

company signed a contract with the U.S. Navy in late 1941 for the

manufacture of 40mm shell casings. Five months later, in March 1942,

it was announced that Motor Wheel had produced a million shell casings.

This was a very short time period to produce this volume as there had to

be time to make the tools and set up the equipment. This was a

significant accomplishment on the part of Motor Wheel.

Assuming production began in December 1941,

this would have been an average rate of 333,333 shell casings per month.

No doubt there was a ramp up time with more casings being produced

in early March 1942 than at the end of 1941. However, if one uses

the 333,333 per month production rate for the remaining 40 months of

World War Two, the Motor Wheel Corporation manufactured at least

13,333,320 40mm shell casings for the U.S. Navy. The company no

doubt produced more than this amount, as it added equipment and became

more experienced in the manufacturing process.

This remotely aimed quad-mount 40mm

anti-aircraft gun on the U.S.S. Hornet CV-12 is expending 40mm

ammunition at an impressive rate in fighting off attacks by Japanese

aircraft in 1945. Ammunition loaders are feeding in four-round clips

as fast as they can be handed to them. Empty shell casings,

some of them possibly made by the Motor Wheel Corporation, litter the

deck. Each barrel for short bursts could fire at a rate of 120

rounds per minute. This scene played out on every 40mm on every

U.S. Navy ship in the Pacific Ocean when under attack. The U.S.

Navy needed ever 40mm shell casing it could produce!

Motor Wheel Corporation was one of the

initial contractors for the U.S. Navy's 40mm program. Production

of the actual shells began in March 1942 with 15,000 rounds produced.

At the beginning of the program, Motor Wheel was producing shell casings

faster than the ammunition factories could turn out the actual rounds.

Production sharply ramped up; and by the end of the war, the U.S. Navy had

purchased a total of 191,559,000 rounds of 40mm ammunition.

The 40mm Bofors anti-aircraft gun is one of

the most iconic weapons of World War Two. The U.S. Navy

procured at least 39,200 40mm Bofors anti-aircraft guns that were

mounted on every type of ship the Navy had during the war.

One of the smallest craft that mounted 40mm

Bofors was the PT boat. This is PT-305 which was built by Higgins

Industries. Author's photo.

Ready ammunition containers behind the

40mm Bofors on PT-305 show the size of the shell casings that Motor

Wheel produced during World War Two. Author's photo.

The U.S. Navy purchased over 10,000 single

mount 40mm Bofors guns that used Motor Wheel shell casings in their

ammunition. This single mount is on the USS Cod. Author's

photo.

This dual mount 40mm anti-aircraft gun is one of nearly 10,000 that

defended Navy ships from aircraft attacks during World War Two.

During Japanese suicide attacks on American ships in the Pacific,

weapons like these used significant amounts of ammunition with Motor Wheel-shell

casings. This example is on the USS Sullivans. Author's

photo.

The battleship USS Massachusetts bristled

with 40mm anti-aircraft guns as did every other battleship during World

War Two. The battleships were large enough to mount the large quad

mounts on the ship. The 40mm Bofors had a rate of fire of 120

rounds per minute. For short bursts, a quad mount like this one could

fire at a rate 480 per minute. The

U.S. Navy needed every one of the over 13million 40mm shell casings

Motor Wheel made during the war. Author's photo.

One of Motor Wheel's first contracts in

November 1941 was for 400,000

75mm semi-armor piercing shell projectiles. Shown here are two

armor piercing shells which are very similar to the semi-armor piercing

type. Author's photo.

How cool is this? This photo is of a Motor Wheel Corporation M72

armor piercing shot with tracer that still exists. Image courtesy

of www.ww2ammo.com

added 7-31-2022.

This image shows the "M.W." designating

Motor Wheel and a date of 1942. Image courtesy of

www.ww2ammo.com

added 7-31-2022.

Mark 10 7.2 Inch Rockets (Hedgehogs):

Motor Wheel built the Mark 10 rocket which was used on destroyers

and destroyer escorts in anti-submarine warfare. Motor Wheel

manufactured the head, tail, fins, and shrouds. They were then sent to a

Naval munitions plant, where either 30 pounds of TNT or 35 pounds of Torpex were added to the head. A small rocket motor was added to

the tail, which gave the weapon a range of 250-280 yards when

it was fired over the bow of the ship.

This U.S. Navy inspector is holding a Mark

10 rocket, as rocket heads move on a conveyor through the paint

shop in the background. Production of the completed 7.2 inch began

for the U.S. Navy in July 1942 with 2,000 manufactured. By the end

of production in February 1945, 509,000 had been made. This was a very

important weapon in the war against the U-boat.

I could not have planned this photo any

better! This photo was taken five years before the writing of this

webpage on the Motor Wheel Corporation, but the docent on the USS Slater

is holding the Mark 10 rocket in a very similar pose to the U.S. Navy inspector in the previous

photo. The photo reveals that the head of the weapon was assembled

from three pieces. The weld line can be seen going around the

radius of the head where the top plate and the main cylinder are joined

together. The spinner on the fuse would not activate the weapon

until it had traveled far enough to keep it from exploding by accident

while still over the ship. The Reo Motor Car Company on the south

side of Lansing could very well have manufactured the spinner and

detonator assembly, as it was a large manufacturer of this product. Author's photo.

Twenty-four Mark 10s were mounted in the

launcher. Each rocket tail was mounted on a long cylinder

called a spigot. The spigots were oriented so that when all 24

projectors were fired in rapid sequence, they fell in an elliptical

pattern 140 by 120 feet, 250-280 yards in front of the moving ship.

The Mark 10 projectors would only detonate on contact with an enemy

submarine. This was unlike the depth charges that were set to go

off at a certain depth. Author's photo.

The USS Slater is the only Cannon Class

Destroyer Escort on display in the world. It is located on the

Hudson River in downtown Albany, NY. Author's photo.

The Mark 10 rockets were deployed from

between the number one and number two gun positions. Author's

photo.

The "Motor Wheel News" makes note that its

rockets were used for shore bombardment during amphibious landings by

American forces. The Mark 10 was modified and with a 3.5-inch

rocket motor and achieved a range of 1,200 yards. These were used

to destroy mines and obstacles in the shallow water at the shoreline.

7.2-inch rockets like those built by Motor Wheel were first used

in mid-1944 and launched from modified LCMs.

The U.S. Army also used a version of the Mark

10 rocket for use as demolition charges fired at enemy positions.

The Army designated it as the T37, which was fired from twenty round

launchers mounted on Sherman tanks. Motor Wheel may have also

produced this weapon for the U.S. Army. However, the historical

record is unclear on this point.

Torpedo Fuel Flasks: Like the

shells, projectiles, and rockets described in the previous section,

Motor Wheel Corporation also built a product for torpedoes that was

totally foreign to its normal civilian product line. Like many

other companies in the United States during World War Two, Motor Wheel

was able to use its engineering and manufacturing capabilities to

produce totally different products for the war effort.

Most likely Motor Wheel built the torpedo fuel

flasks for the Pontiac Motor Division of General Motors in nearby

Pontiac, MI. Pontiac produced 4,526 Mark XIII aerial torpedoes for

the U.S. Navy. International Harvester built another 763 Mark XIII

aerial torpedoes at its McCormick Works in Chicago, IL. It would

have made sense for Motor Wheel to supply both nearby companies with the

same type of part. This would have made a total of 5,289 Mark

XIII torpedo fuel flasks. Other types of torpedoes for surface ships

and submarines along with the Mark XIII were also built by the Amertorp

Corporation in Forest Park, IL, a suburb of Chicago, IL. It

produced a total of 8,391 torpedoes. If Motor Wheel produced fuel

flasks for these three companies, it would have manufactured 13,680 of

the components. The other torpedo manufacturing plants were on the

east coast which would probably have had different suppliers for the

product. In total, 57,653 torpedoes of all types were produced

during World War Two.

The Mark XIII aircraft torpedo. The

thirteen-foot long weapon consisted of 1,225 assemblies of 5,222

individual parts. The gyro, which guided the weapon to its target,

turned at 9,000 rpms. It had a diameter of

22.5 inches and weighed 2,216 pounds, of which 600 pounds was the Torpex

explosive. The internal steam turbine propelled the Mark XIII at 33 knots

for a maximum range of 6,300 yards. The Naval Torpedo Section, Amertorp

Corporation, Pontiac, and International Harvester produced the Mark XIII

during World War Two. The four companies built 17,000 torpedoes.

1,500 were used in combat. Author's photo.

Motor Wheel was contracted during World War

Two to manufacture brass fuel flasks for torpedoes used by both

U.S. Navy submarines and torpedo bombers. This

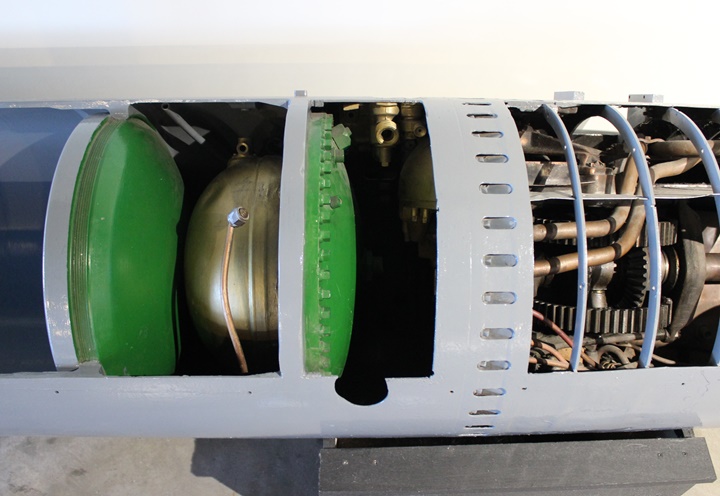

"Motor Wheel News" photo shows the flasks being assembled from two separate

stamped pieces during World War Two. Note the brass fittings

on the sides of the flasks in the photo. Author's photo.

The Motor Wheel-built brass fuel flask can be seen in this cutaway of a

submarine type torpedo. The brass fitting can be seen at the top

of the flask. Author's photo.

The Motor Wheel Corporation Plants:

The company had a large complex of several manufacturing plants on the

north side of Lansing bounded from south to north by East Saginaw Street

to McKinley Street. The western boundary was Larch Street. I

lived on the south side of Lansing and was only vaguely aware of the

Motor Wheel plants. I was most aware of the large plant just east

of Larch Street which was visible as I traveled north out of Lansing to

Camp Grayling.

This is the former the corporate offices of

the Motor Wheel Corporation. During World War Two, the address was

716 East Saginaw Street. Until I started researching the company,

I was unaware of this plant. While I lived in Lansing, I should

have had occasion to drive by this location and notice it. The

reason I probably did not notice this building is that in 1961, Motor

Wheel moved its headquarters to Plant 2 on Larch Street. It

also then demolished the large factory complex at this location.

It is unknown why this particular building was saved. By the time I

would have driven by, there would have been no "Motor Wheel" sign on the

building nor large factory complex to look at.

In any case, this is an elegant looking

structure which today has been repurposed into the Motor Wheel Lofts

with a current address of 707 Prudden Street. Originally, this

structure was the factory for the Prudden Wheel Company, making this

building over 100 years old. This building is L-shaped and is the

only building of the factory complex still standing. It is

listed on the National Register of Historic Places as the Prudden Wheel

Company Building. The author's photo is looking west down the

south side of the building.

This is the west side of the structure.

During World War Two there were four sets of railroad tracks in this

area. The building in the left portion of the photo is a new

structure that replaced the former razed factory buildings.

Author's photo.

This photo is looking northwest at the

repurposed former Motor Wheel corporate offices and factory complex.

The smoke stack has the name "Prudden' on it. Author's photo.

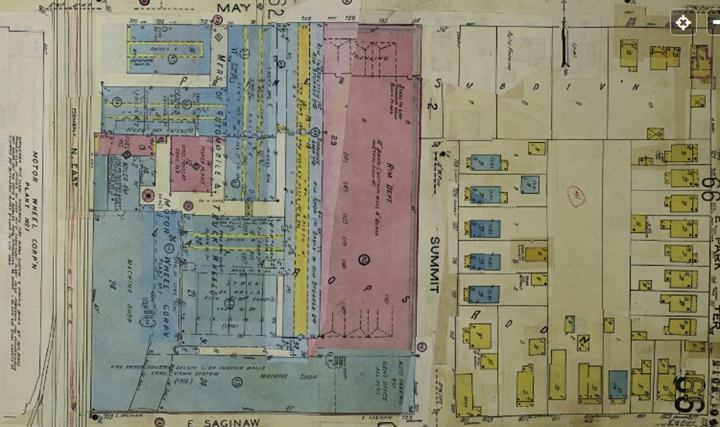

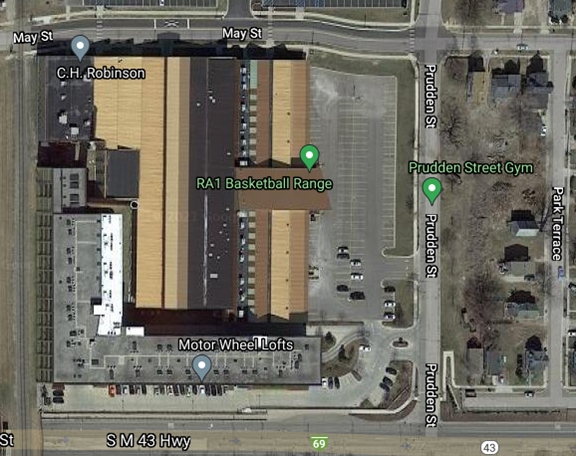

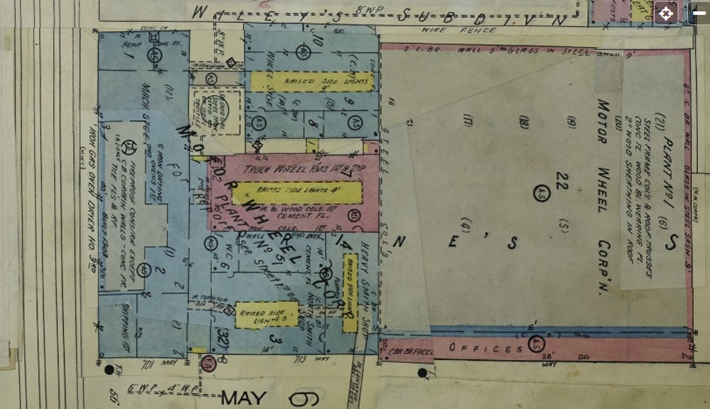

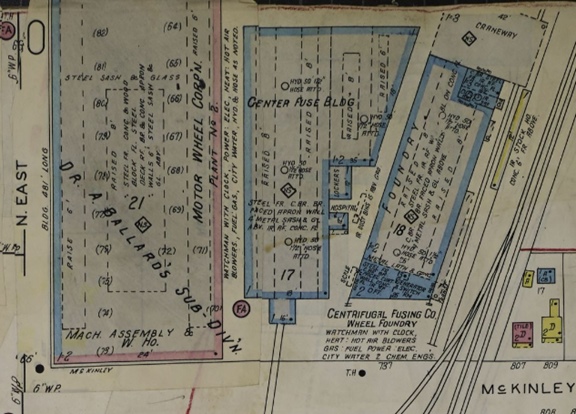

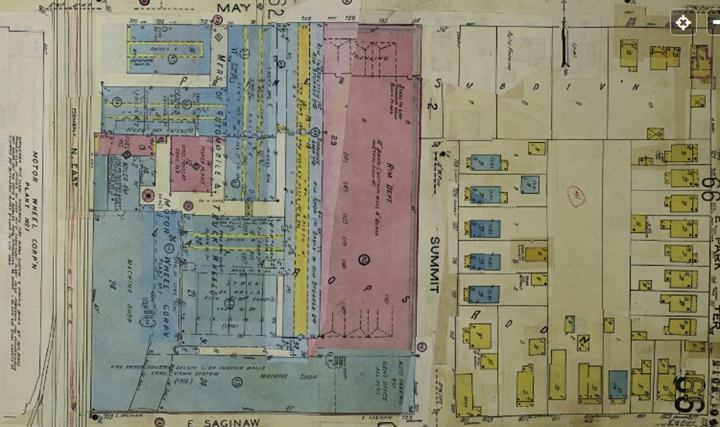

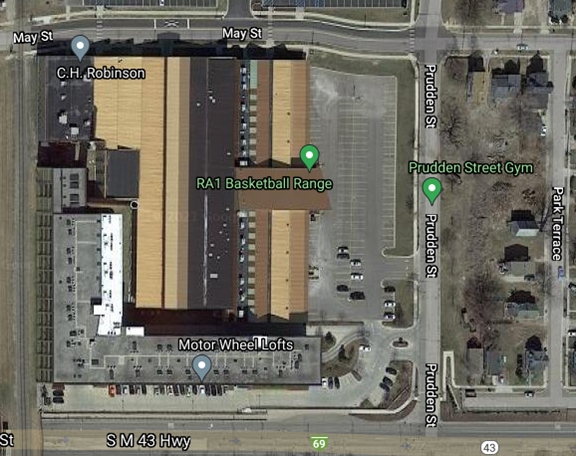

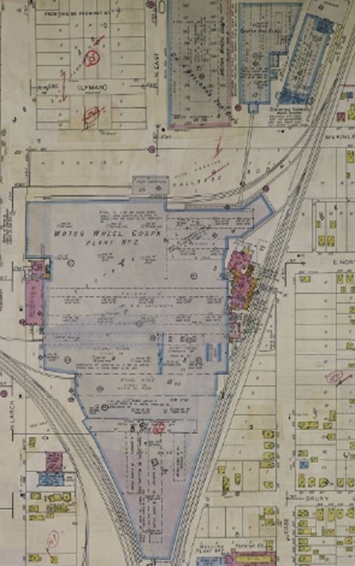

This Sanborn map shows the complex in 1951. Today Summit Street is

Prudden Street. As the current Google Maps satellite image below

confirms, most of the original structure was razed, with only the

L-shaped original building still standing. A comparison of the two

images shows that where the rim department used to be in 1951 is now a

parking lot. The east end of the L-shaped building was a parking

garage and offices. It no longer exists either.

Note that May Street is the northern boundary

to this facility. Satellite image courtesy of Google Maps.

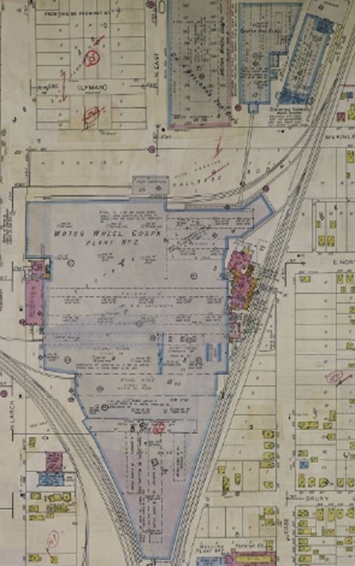

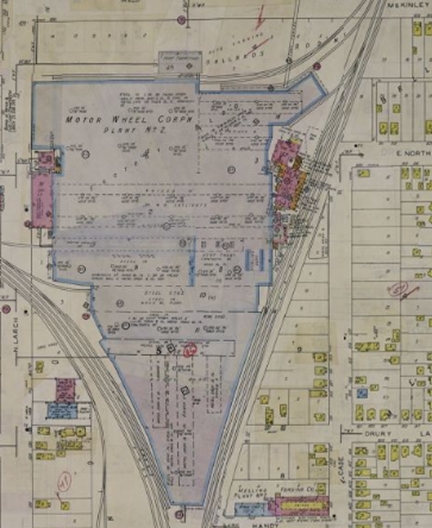

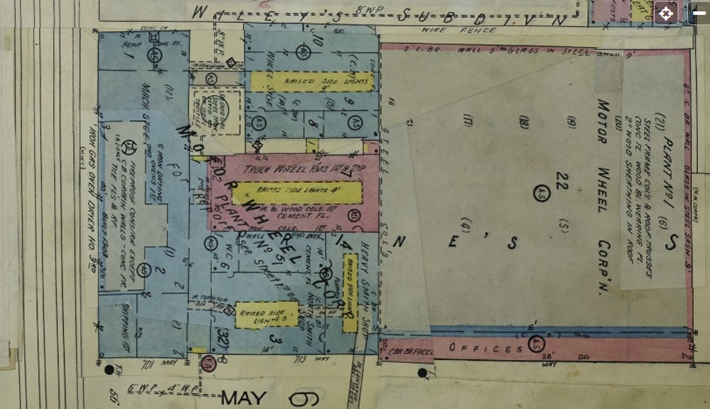

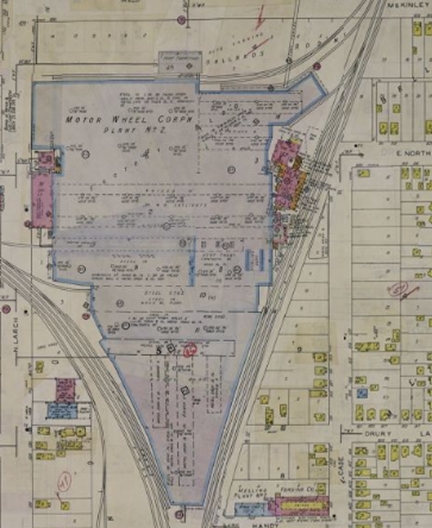

This Sanborn map shows that Motor Wheel

Corporation Plant No. 1 was directly to the north of the Saginaw Street

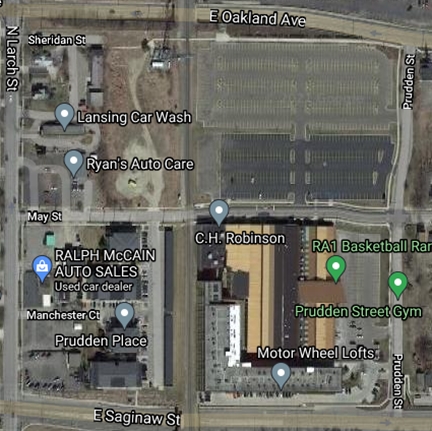

plant. It was also razed in 1961 and today is a parking lot.

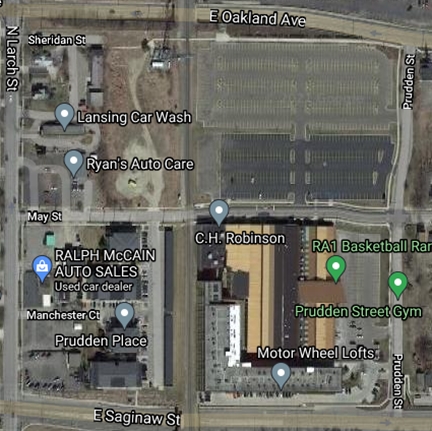

This current satellite image shows the

entire former two Motor Wheel plant locations as they are today.

Satellite image courtesy of Google Maps.

This is the Motor Wheel complex I remember

on North Larch Street, which was the western boundary to the facility.

McKinley Street was the northern boundary to

Motor Wheel plant 2.

The former Motor Wheel plant that I remember still exists. In the

1970s I would see it from the U.S. 27 overpass each summer as I went to

and from Camp Grayling in northern lower Michigan. Satellite image

courtesy of Google Maps.

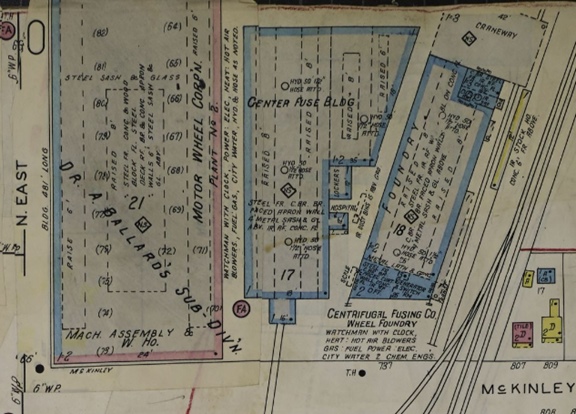

Centrifugal Fusing Company was on the north

side of McKinley Street. The company used the centrifugal casting

method to make truck

and aircraft brake castings for Motor Wheel during World War Two.

Directly to the west of Centrifugal Fusing was a Motor Wheel plant.

In 1937, Motor Wheel built the two plants and then leased them to

Centrifugal Fusing in order to have its supply of brake castings next to

the Motor Wheel complex.

The former Motor Wheel and Centrifugal

Fusing factory complex still exists. The railroad tracks that were

the eastern boundary of the complex have been removed. McKinley

Street is now blocked where the railroad tracks used to be, and McKinley Street in front of the complex is now private property.

In 1984, Goodyear, the owner of Motor Wheel at the time, spun off the

centrifugal casting operation and the associated machining operation

into another company that moved the operations to Chattanooga, TN.

Today that new company continues the name of "Motor Wheel."

Satellite image courtesy of Google Maps.

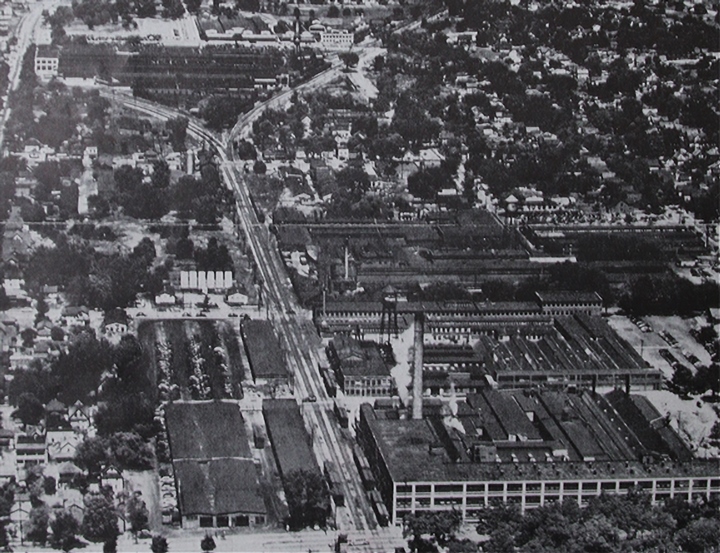

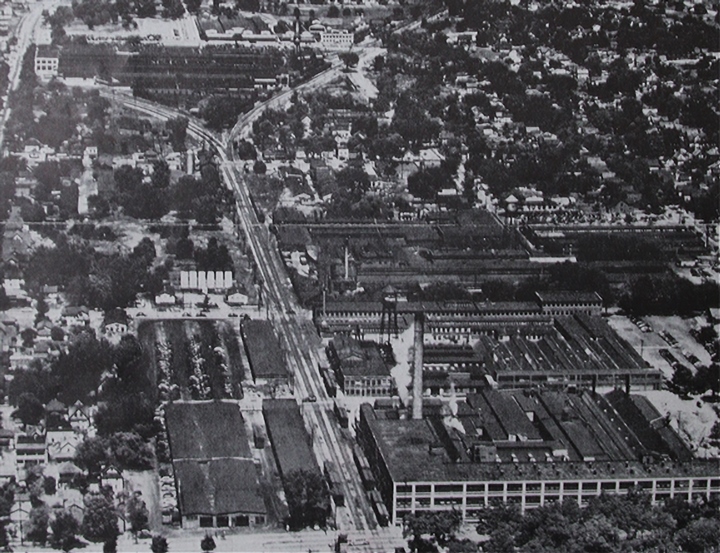

This 1945 aerial photo shows the Motor Wheel

Corporation looking north. Image added 12-25-2021.

In December 1945 Motor Wheel purchased this

factory at the corner of South Washington Avenue and West Mount Hope

Avenue in Lansing, MI. The plant was purchased from the

Reconstruction Finance Corporation. During World War Two

Nash-Kelvinator built aircraft propellers in this factory. Prior

to World War Two, Motor

Wheel Corporation had developed a furnace it

marketed under the name "Duo-Therm." After World War Two, this

factory was dedicated to building furnaces. This plant was in my

neighborhood, and I remember a big Motor Wheel Corporation sign on the

top of this factory. By 1961, Motor Wheel had vacated this

building, and it was the location for the first large discount store in

Lansing. Apparently, the Duo-Therm business proved not to be as

profitable for the company as expected.

This is the plant today. During World

War Two, my grandfather worked in this plant supervising mostly women

workers in the propeller balancing department.

Author's photo. |