|

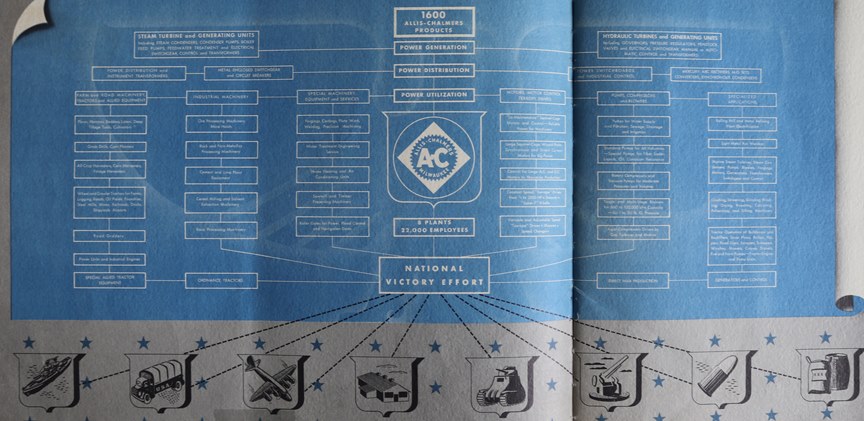

We Work for Victory, and We

Plan for Peace

Allis-Chalmers in World War Two

Milwaukee, WI

1901-1998

This page updated

3-4-2025.

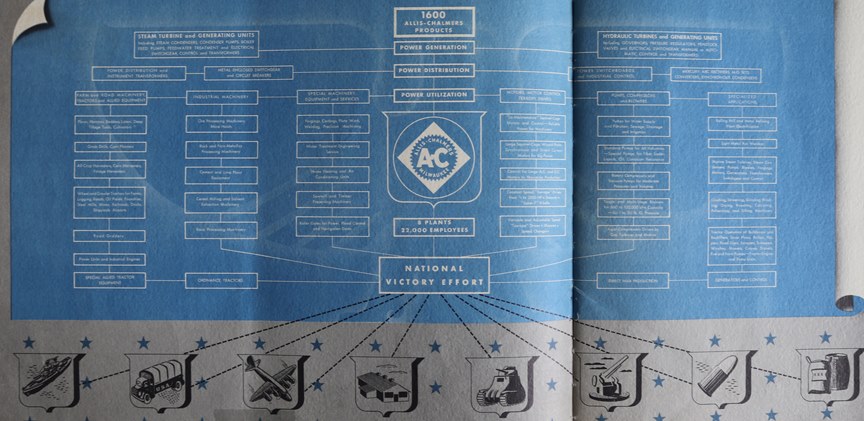

The Allis-Chalmers name is best known to the

general public for its manufacture of farm and construction equipment.

For the World War Two historian, the company is best known for the

production of the M4 High Speed Tractor. Allis-Chalmers had a more

diverse product line before and during World War Two, well beyond building

tractors and combines. During World War Two the company's 32,000

employees in eight plants built 1,600 products; most of them

non-military in nature. Allis-Chalmers produced steam and

hydraulic turbines, electrical generators and the associated electrical

switchgear, transformers, and circuit breakers. The company

produced equipment for the conversion of raw materials into useful

metals needed for the war effort. Its industrial electrical motors

were used in steel and other metal processing plants to drive the

equipment which processed the metals into useful products. On

the agricultural front, Allis-Chalmers continued to produce needed farm

equipment, and the equipment needed by the food processing industry

to provide food for both civilian and military needs. The

company's equipment was also used in the chemical, textile, rubber,

wood, paper, petroleum, and rubber industries.

Allis-Chalmers was the "conglomerate" of its

time, long before the term was applied to diverse product

companies of the 1960s.

Allis-Chalmers

Manufacturing Company, Tractor Works, Springfield, IL won the Army-Navy

"E" Award three times during World War Two.

Allis-Chalmers Manufacturing Company, Electrical Control Plant,

Milwaukee WI, won the Army-Navy "E" Award five times during World War

Two.

Allis-Chalmers Manufacturing Company, Supercharger Works, Milwaukee, WI

won the Army-Navy "E" Award four times during World War Two.

Allis-Chalmers Manufacturing Company, West Allis Works, Milwaukee,

WI.won the Army-Navy "E" Award five times during World War Two.

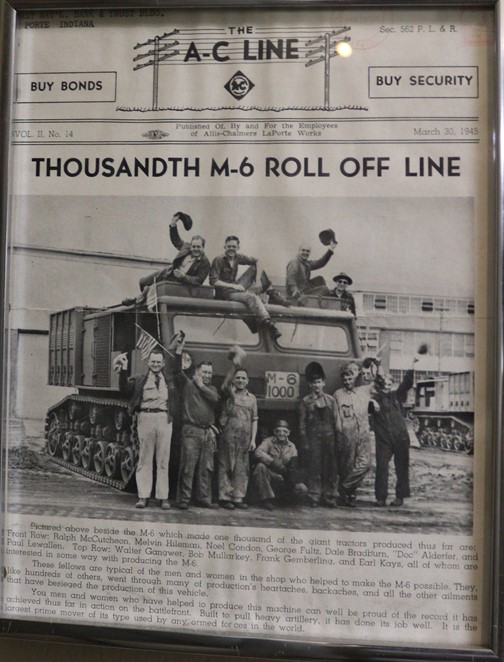

Allis-Chalmers Manufacturing Company, LaPorte Works, LaPorte, IN won the

Army-Navy "E" Award two times during World War Two.

Allis-Chalmers World War Two Military

Products: Table 1 shows that the nine Allis-Chalmers plants

had a total of $660,875,000 in major contracts during World War Two.

The company built propeller shafts for destroyers, cruisers, and

submarines. It also built 90mm anti-aircraft guns, slides for 16-inch naval guns,

aircraft turbo superchargers, 434 snow trailers, and at least 11,249

tractors of various types. These were just a few of the many

diverse products Allis-Chalmers manufactured to help win World War Two.

|

Table 1 -

Allis-Chalmers Major Contract Summary by Plant Location - Table

added 11-18-2023. |

|

Plant Location |

Contract Amount |

Products |

Customers |

|

Appleton, WI |

$113,000 |

Service Propulsion Machinery |

Navy |

|

Boston, MA |

$2,457,000 |

Ship

Hatches and Bulkhead Frames, Oil Circuit Equipment, Gas Mask

Parts |

Army,

Navy, Treasury |

| La

Crosse, WI |

$3,321,000 |

Snatch Blocks, Rope, Steel, Tractor Plows, Agricultural

Equipment |

Army,

Navy, Treasury |

| LaPorte, IN |

$66,640,000 |

Gun

Mounts, Snow Tractor Parts, M6 High Speed Tractors |

Army |

|

Milwaukee, WI |

$46,648,000 |

Turbine Generator Sets, Tractors, Pumps, Road Machinery,

Airplane Equipment, Transformers, Shafting, Fire Pumps, Ore

Crushers, Generators, Turbines, Machine Tools, Circuit Breakers,

Ordnance Equipment, Farm Equipment, Voltage Regulators, Machine

Tools, M1 Tractors, Motors, Anchor Shackles, Pulley Blocks, Snow

Tractors and Trailers, Hoists |

Army,

Foreign, Maritime, Commission, Navy, Treasury |

|

Norwood, OH |

$4,110,000 |

Condenser Pumps, Circulating Pumps, Centrifugal Pumps, Engine

Starting Motors, Electric Motor Controls |

Navy,

Treasury |

|

Pittsburgh, PA |

$1,399,000 |

Electric Transformers |

Army,

Navy, Treasury |

|

Springfield, IL |

$246,621,000 |

Tractors, Tractor Parts, Medium Tractors M1, Tractors M4,

Ordnance Material, Tractors, HD7, Tractors HD10, Tractors HD14,

Turbo Generator Sets |

Army,

Treasury |

| West

Allis, WI |

$289,566,000 |

Breech Forgings, Lab Equipment, Gun Forgings, Ship Propulsion

Turbines, Shaft Couplings, Tractors, Farm Machinery, Airplane

Parts, Steel Forgings, Gun Mounts, Turbine Blades, Sub Stations,

Machine Parts, Snow Tractors T26, Generator Motors, Turbo

Supercharger Assemblies, Triple Turret Slides, Turbine Gears,

Turbine Rotors, Armatures, Fire Pumps, Steering Gear Equipment,

Power Units, Electric Switchboards, Shaft Forgings, Turbo

Generator Sets, Farm Tractors, Buckets, Condensate Pumps, Radio

Sets, Centrifugal Pumps, Voltage Regulators, Hoists, Ball Mills,

Ball Mills, Condenser Ejectors, Electric Sub Stations, X-Ray

Machines, Aircraft Rocket Launch Devices |

Army,

Foreign, Maritime, Commission, Navy, Treasury |

|

Total |

$660,875,000 |

|

|

Table 2 - Allis

Chalmers Tractors and Trailers

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch,

January 21, 1946. |

|

Type |

Same as |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tractors |

|

|

|

|

|

|

|

|

| Medium, M1 |

Cat D6, Cleveland M1, IH

TD14 |

168 |

211 |

930 |

1424 |

* |

* |

2,733 |

| High-speed, 18-ton, M4 (90mm gun) |

|

|

|

|

1045 |

1248 |

171 |

2,464 |

| High-speed, 18-ton, M4 (155 mm gun and 8 in

howitzer) |

|

|

|

|

599 |

1663 |

826 |

3,088 |

| High-speed, 18-ton, M4A1 |

|

|

|

|

|

|

259 |

259 |

| Medium (Winterized), D6 |

Cat D6 |

|

|

|

67 |

* |

* |

67 |

| Medium, Diesel, 45 hp |

IH |

|

|

|

245 |

* |

* |

245 |

| Heavy, M1 |

Cat D7, IH TD18 |

136 |

40 |

315 |

256 |

* |

* |

747 |

| High-speed, 38 -ton, M6 |

|

|

|

|

|

724 |

511 |

1,235 |

| Crane, 1-ton, M1 |

IH |

17 |

|

|

|

|

|

17 |

| Wheeled, Light, M3 |

|

96 |

|

|

|

|

|

96 |

| Snow, T26 |

|

|

|

6 |

|

|

|

6 |

| Snow, T27 |

|

|

|

|

1 |

|

|

1 |

| Snow, M7 |

|

|

|

|

|

291 |

|

291 |

| Total Tractors |

|

417 |

251 |

1,251 |

3,637 |

3,926 |

1,767 |

11,249 |

| Trailers |

|

|

|

|

|

|

|

|

| 1-ton, Snow, M19 |

|

|

|

|

|

434 |

|

434 |

Author's Note

and Disclaimer: The Detroit Office

of Ordnance of the U.S. Army was the primary purchasing entity for

vehicles for the U.S. Army during World War Two. It also purchased vehicles

for the USMC, US Navy, and for Lend-Lease. However, there were

other organizations that also purchased vehicles including the Army

Corps of Engineers, U.S. Army Air Force, U.S. Army Signal Corps, Navy

Bureau of Ordnance, Navy Bureau of Aeronautics, and foreign countries

making direct purchases.

*Starting in 1944, the Army Corps of Engineers

became responsible for the purchase of low speed tractors which, until

then, had been

the domain of Army Ordnance. Therefore, the totals for

these types of tractors are incomplete. At the same time as noted above,

other branches of the US military were also making their own purchases, making

the totals even more inaccurate.

Jet Engine Research: In 1941 the

US Navy gave both Allis-Chalmers and Westinghouse 18-month contracts for

the development of an aircraft jet engine. Both were picked

because they built steam turbines for electric energy production, and it

was felt the technologies were similar. In 1943 the Navy chose to

go ahead with Westinghouse as the sole source.

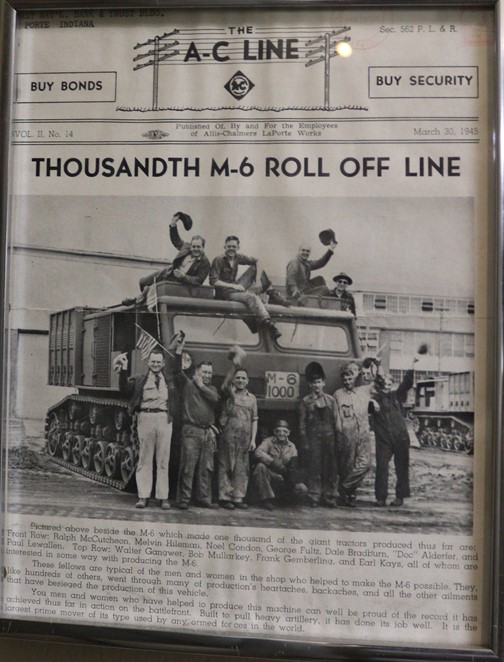

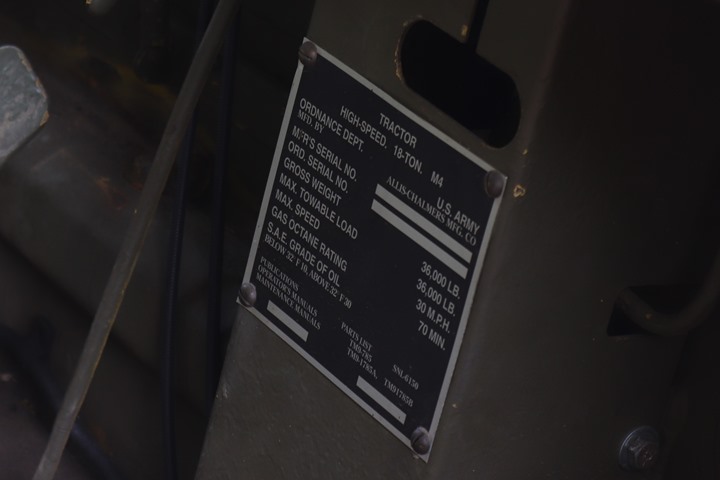

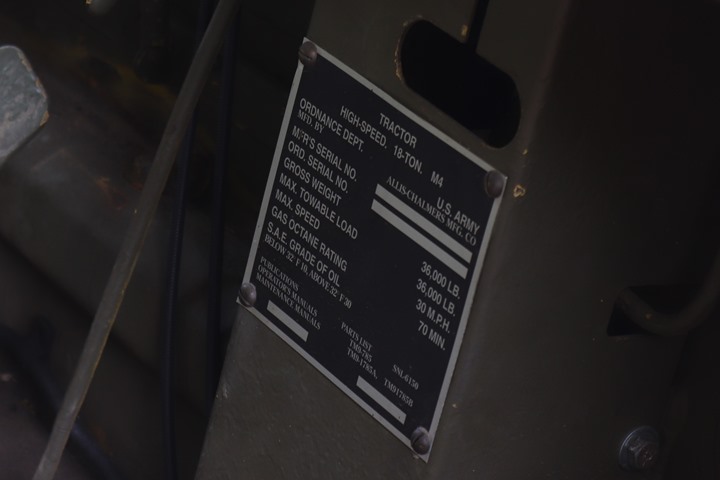

M6 High Speed Tractor: 1,235 of

these 38-ton tractors were built in 1944-45 at the Allis-Chalmers LaPorte, IN Works. There are only two known to still exist; one in The

Netherlands, and one at the Indiana Military Museum in Vincennes,

IN, 250 miles from where it was originally built. It is in need of

extensive restoration, as can be seen below.

The Indiana-built M6 is located outside with

a lot of other equipment the museum purchased. Hopefully, it

is waiting for

restoration when time and funding becomes available. Author's photo

added 1-25-2019.

Author's photo added 1-25-2019.

Author's photo added 1-25-2019.

Author's photo added 1-25-2019.

Author's photo added 1-25-2019.

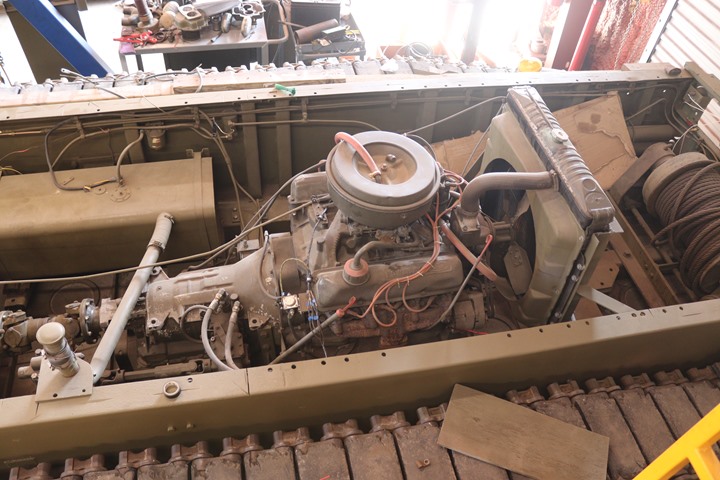

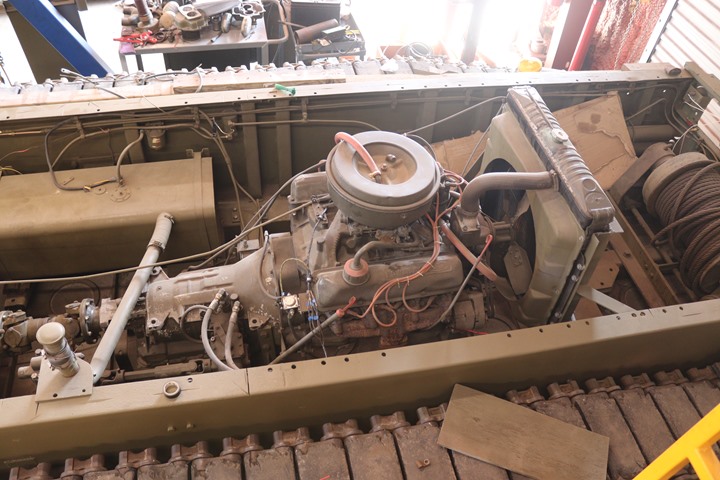

The original engines in the M6 were two Waukesha 145GZ

six-cylinder gasoline engines each producing 190 h.p.

However, a previous owner replaced the Waukesha engines with Cummins NH

diesels. Interestingly, someone from the museum has been out recently doing some

work on both engines, as evidenced by the cans of lubricant left on the

vehicle. Author's photo added 1-25-2019.

The valve covers on the Cummins

engines consist of two pieces. The rear section on each has new

un-rusted bolts in it. On the front section, the top of the valve

cover is missing, and the rusted rocker arms can be seen. The intake

manifold on the yellow painted engine has been disconnected.

Author's photo added 1-25-2019.

Author's photo added 1-25-2019.

The two engines are different colors,

indicating that one was replaced during the M6's useful lifetime.

Author's photo added 1-25-2019.

On April 6, 1944, it was announced that the

La Porte Works would begin production of the M6 High Speed Tractor.

On September 21, 1943, the LaPorte Works received its first Army-Navy

"E" Award; and March 9, 1944, its second. Both of these dates

preceded the production of the M6, the only known "military" product for

the plant. There was also grader production at the plant, and

these two awards may have been for that.

During the war, the plant had 3,200 workers.

M6 work stopped on January 20-23, 1945, due to a labor dispute at the

plant.

M4 High Speed Tractor: A total of 5,811

were built in three different versions as shown above in the table.

Production of the M4 was in the Springfield, IL Tractor Works. It

was the first tractor plant to win the Army-Navy "E" Award. Below

are several of the 33 known remaining Allis-Chalmers-built M4 High Speed

Tractors.

This M4 is on display at the World War II

American Experience in Gettysburg, PA. Author's photo added

1-31-2025.

This M4 is part of the large collection of

World War Two vehicles at the National Museum of Military Vehicles in

Dubois, WY. Author's photo added 1-31-2025.

This M4 is on outside display at the

Heartland Military Museum in Lexington, NE. Author's photo added

3-4-2025.

This view of the engine compartment shows at

least five V-belts. Author's photo added 3-4-2025.

This totally restored and running M4 is

owned by the Museum of American Armor in New Bethpage, NY.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

This is on display at the Museum of the

Kansas National Guard in Topeka, KS. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Another M4 is sitting in the corner of the parking

lot of the

Georgia Rural Telephone Museum in Leslie, GA. This was equipped

after the war with an implement for installing buried telephone cables. Author's photo.

Author's photo.

Author's photo.

Author's photo.

World War Two Armor Allis-Chambers M4 High Speed

Tractor Restoration: The next set of photos starts with photos

I took of the WW2 Armor M4 High Speed Tractor while undergoing

restoration in March 2019 at the organization's facility in Osteen, FL.

Next are photos of the restored M4 at the 2019 Conneaut D-Day event in

August 2019 in Conneaut, OH. What excellent work! WW2 Armor

also has a newly restored 155mm Long Tom that the M4 can pull, showing

exactly how it was utilized during World War Two. This is such

excellence to detail by the staff at WW2 Armor.

This Allis-Chalmers M4 High Speed Tractor is part of the collection of

equipment at WW2 Armor in Osteen, FL. It is being restored to operating

condition to pull the group's 155mm Long Tom. Author's photo added

3-24-2019.

With the body of the tractor off, one can

see the layout of the chassis and the drivetrain. The fuel tank

is at the top of the photo. Author's photo added 3-24-2019.

The original Waukesha inline six-cylinder engine has been replaced by a

Ford V-8. Author's photo added 3-24-2019.

Author's photo added 3-24-2019.

The WW2 Armor M4 High Speed Tractor and 155mm Long Tom on the beach at

Conneaut, OH. Later, the M4 would pull the Long Tom down to the

water's edge for the reenactment of D-Day. Everything is

functional on WW2 Armor equipment. The Long Tom fired blanks from

the edge of Lake Erie during the reenactment. As an added note, the

carriage for the Long Tom was built by the Rock Island Arsenal in

Illinois during World War Two.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

The crew is preparing for the reenactment.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Author's photo added 8-22-2019.

Another M4 High Speed Tractor chassis is outside at WW2 Armor in

Osteen, FL. Author's photo

added 3-24-2019.

Author's photo added 3-24-2019.

This M4 High Speed Tractor is rusting away

out in the elements at the Russell Military Museum in Zion, IL.

Author's photo added 7-29-2019.

Author's photo added 7-29-2019.

Author's photo added 7-29-2019.

Low Speed Tractors:

Table 3 - Allis-Chalmers

Low Speed Tractors

Accepted by Detroit Ordnance, US Army

As noted above, the Army Corps of Engineers took over

acceptance of low speed tractors on January 1, 1944.

Those numbers are not available along with the number of

Allis-Chalmers types purchased by the US Navy for use by its

Construction Battalions (Seabees). During 1944 and

1945, military demand for low speed tractors

increased dramatically, with the planned invasions of Europe and

Japan. The total for the M1 Heavy is particularly under-represented. |

|

Type |

Allis-Chalmers Model |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Medium, M1 |

HD-7W |

168 |

211 |

930 |

1424 |

* |

* |

2,733 |

| Medium (Winterized), D6 |

|

|

|

|

67 |

* |

* |

67 |

| Medium, Diesel, 45 hp |

|

|

|

|

245 |

* |

* |

245 |

| Heavy, M1 |

HD10W |

136 |

40 |

315 |

256 |

* |

* |

747 |

| Crane, 1-ton, M1 |

HD-7W |

17 |

|

|

|

|

|

17 |

| Wheeled, Light, M3 |

|

96 |

|

|

|

|

|

96 |

| Total Tractors |

|

417 |

251 |

1,251 |

1,992 |

|

|

3,905 |

This 1947-1950 Allis-Chalmers HD19 is

essentially similar; but it is bigger than the

World War Two HD10 and equipped with a six-cylinder Detroit Diesel

engine rather than a

four-cylinder engine. It was also two tons heavier. Author's photo.

On display at Fort Polk, LA is this post-World

War Two HD-16, introduced in 1955. Allis-Chalmers had been using Detroit Diesel engines

until 1955. But with the recent

purchase of Buda Engines, it began installing Buda engines under the

Allis-Chalmers name. Author's photo.

Author's photo.

Author's photo.

Author's photo.

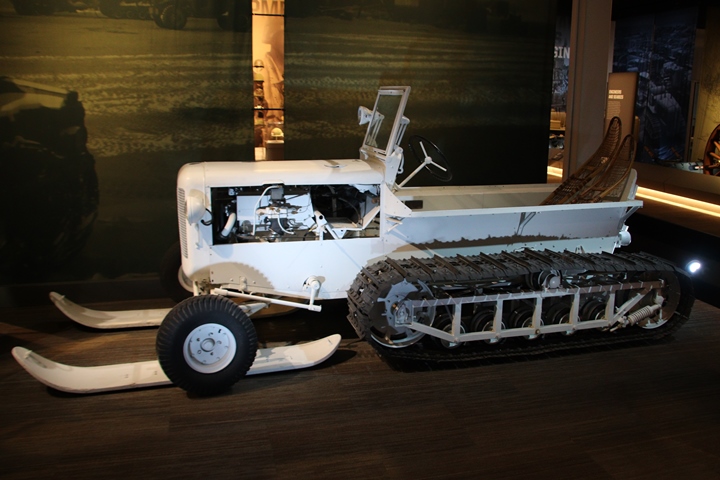

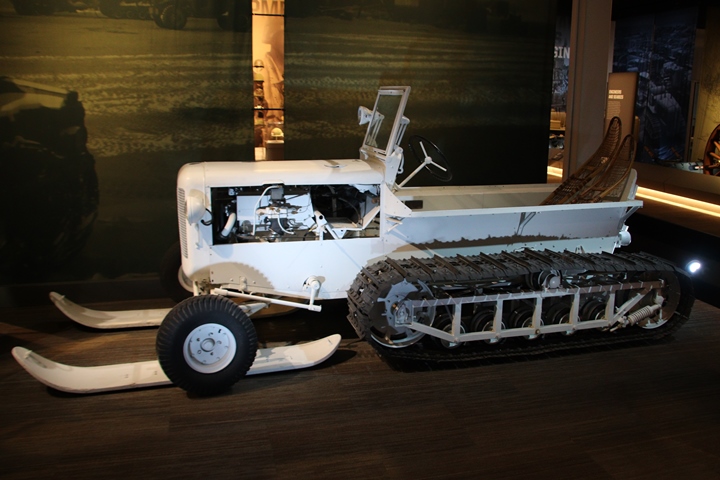

M7 Snow Tractors: 298 snow tractors

were built by Allis-Chalmers during World War Two, with 291 them being

the M7 like the ones shown below. The three shown below are of the

only 20 known to still exist.

This M7 snow tractor is on display at the

Heartland Museum of Military Vehicles in Lexington, NE. Author's

photo added 11-18-2023.

Author's photo added 11-18-2023.

Author's photo added 11-18-2023.

Author's photo added 11-18-2023.

Author's photo added 11-18-2023.

Author's photo added 11-18-2023.

This M7 is on display at the National

Museum of Military Vehicles in Dubois, WY. Author's photo added

11-18-2023.

This Allis-Chalmers M7 Snow Tractor,

serial number 283 of 291, is owned by Roberts

Armory in Rochelle, IL. Author's photo.

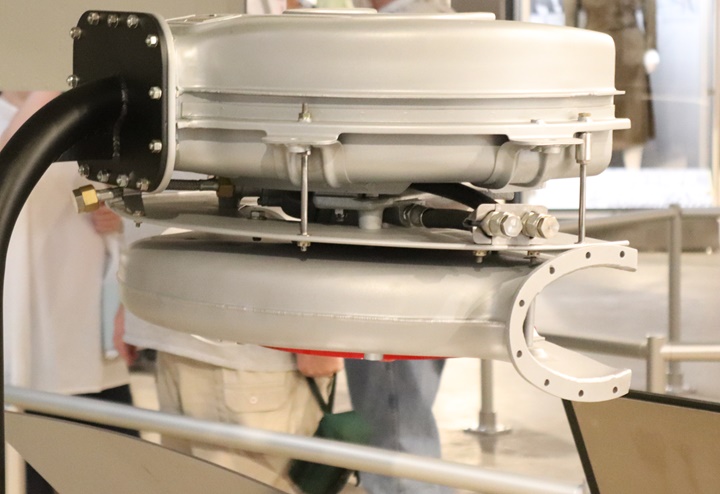

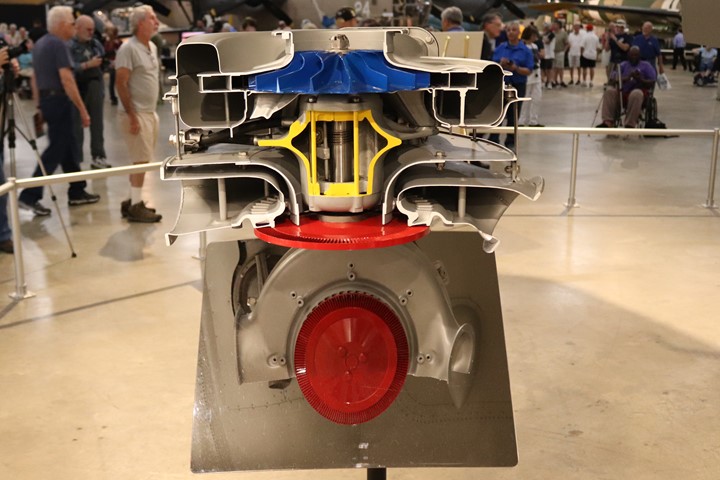

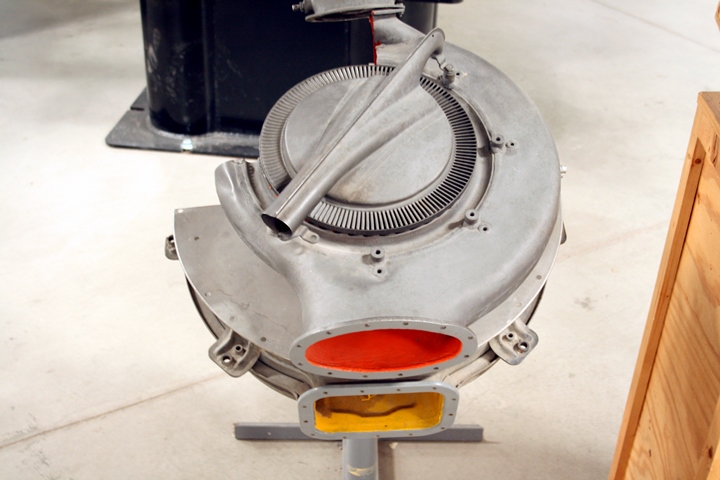

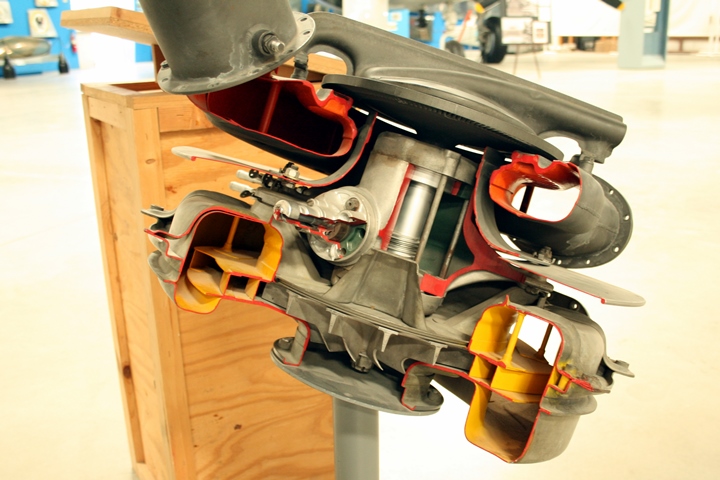

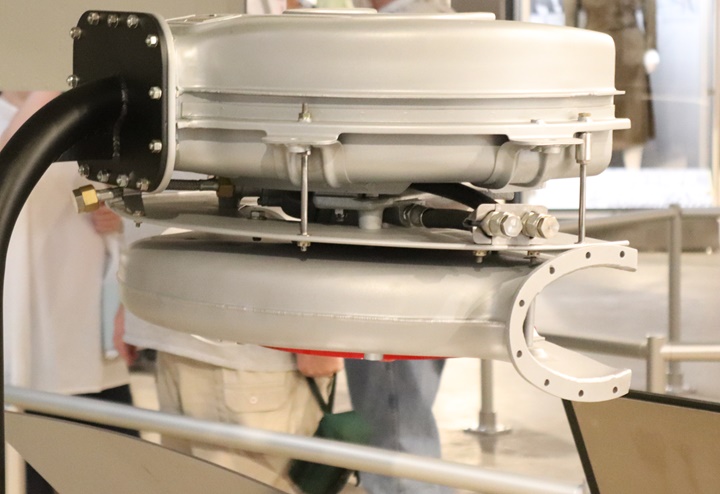

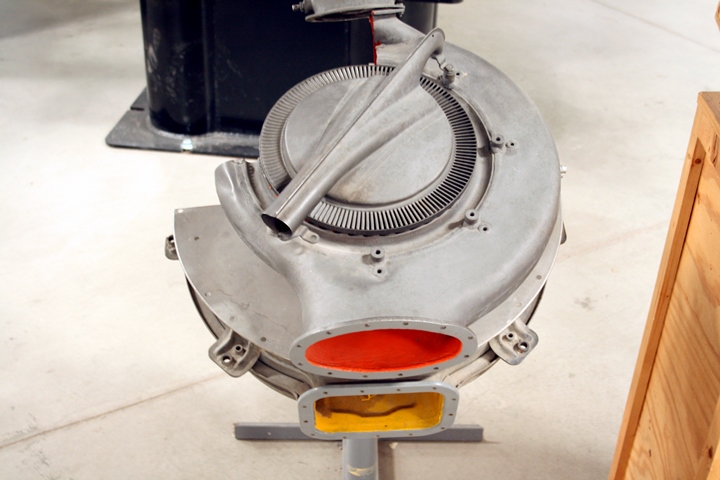

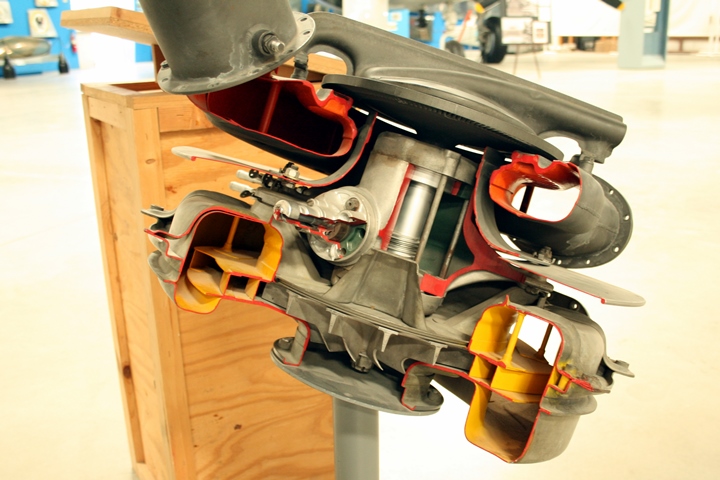

Aircraft Turbo superchargers:

Allis-Chalmers had a dedicated plant in Milwaukee, WI, building GE turbo

superchargers under license. The P-38, P-47, B-17, B-24, and B-29

aircraft used the device. The B-29 used two turbo

superchargers per engine, while the remaining aircraft used one per

engine.

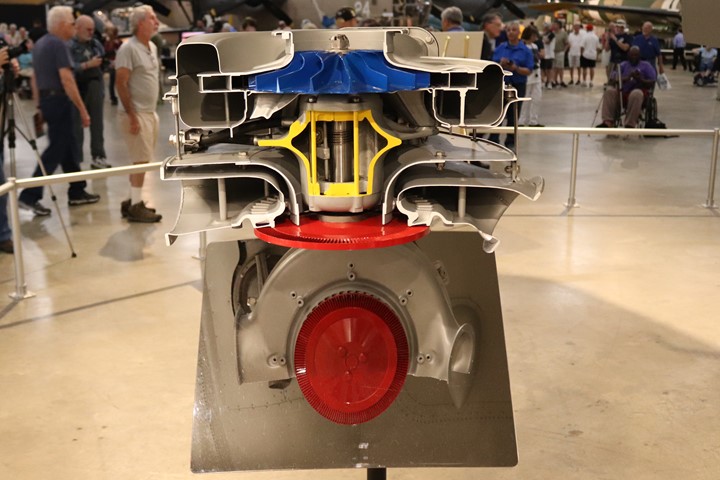

The B-17 display at the National Museum of

the United States Air Force in Dayton, OH has an excellent display on

the aircraft supercharger. Author's photo.

It is unknown which of the three

companies built the supercharger on display at the Memphis Belle.

This one shown here could have been built by Allis-Chalmers, the Ford

Motor Car Company, or General Electric. Author's photo.

This cut-a-way has a mirror, so the

bottom of the unit can be seen. Author's photo.

Author's photo.

The turbo supercharger on the B-17 was

located along the bottom of the wing behind each engine. Not

counting spares, 50,768 turbo superchargers were needed for B-17 production

during World War Two. Author's photo.

This turbo supercharger on display at the

Pima Air and Space Museum in Tucson, AZ is identified as one that was

built by Allis-Chalmers. Author's photo added 11-18-2023.

Author's photo added 11-18-2023.

90mm Anti-Aircraft Guns:

Allis-Chalmers was the first company during

World War Two to start building the 90mm Anti-Aircraft gun.

Author's photo.

Ship's Propeller Shafts:

Allis-Chalmers built propeller shafts for US Navy destroyers, cruisers,

and submarines. Work on the propeller shafts included forging,

shaping, and boring.

The USS Kidd is a Fletcher Class Destroyer

that is typical of destroyers utilizing Allis-Chalmers built propeller

shafts. The propeller shaft can be seen in the lower left hand

section of the photo. Author's photo.

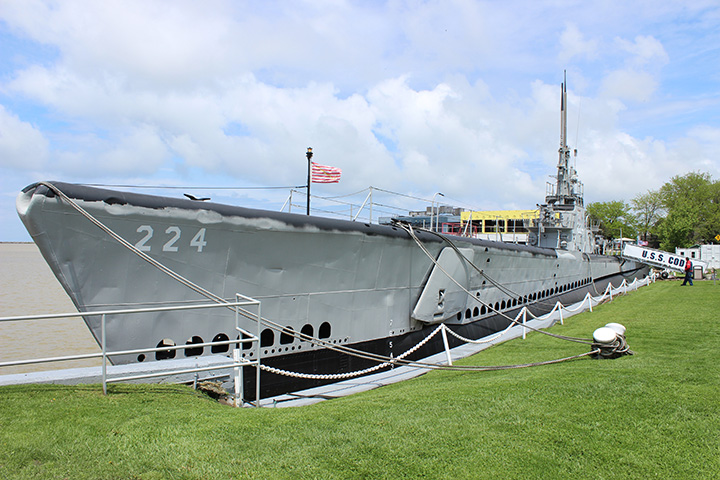

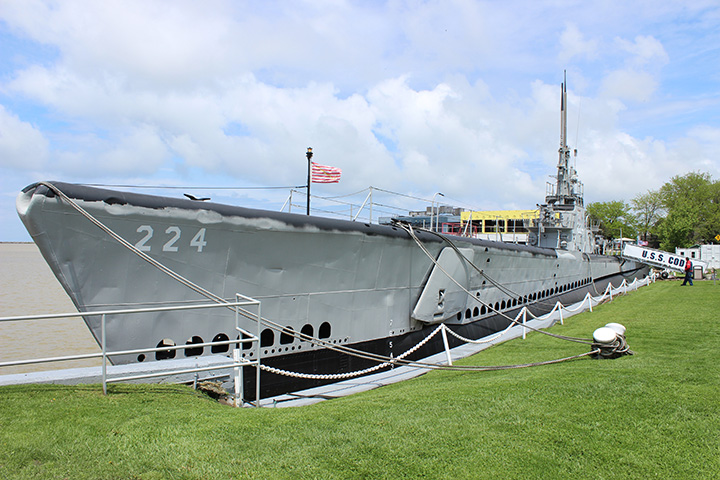

The USS Cod is typical of the many US Navy

submarines built with Allis-Chalmers propeller shafts. Author's

photo.

16-Inch Battleship Gun Cradles:

Allis-Chalmers built gun cradles for the 16-inch main guns used on US

Navy battleships.

The USS Alabama was armed with 16-inch main

guns. It was one of eight battleships built during the World War

Two era armed with nine 16-inch guns. Author's photo.

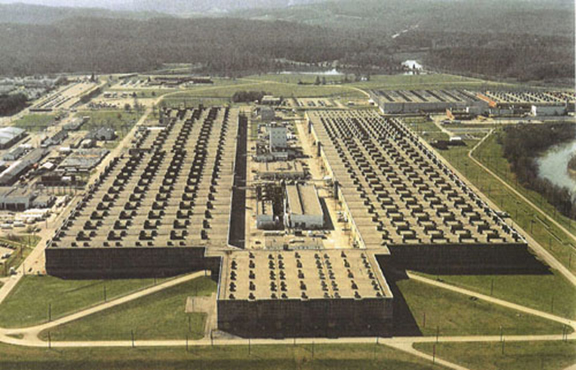

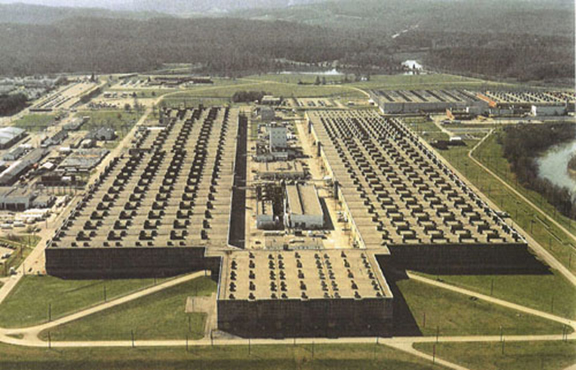

Manhattan Project: Allis-Chalmers-built compressors were used to handle Uranium hexafluoride at

the K-25

separation plant in Oak Ridge, TN. K-25 used the gaseous diffusion

process to separate the fissionable U-235 from U-238.

K-25 was a mile long and the largest factory

in the world during World War Two. It was torn down in 2016.

The Allis-Chalmers compressors in K-25

helped produce the 30 pounds of U-235 used in the Little Boy atomic

bomb.

LaPorte, IN Works:

The former Allis-Chalmers LaPorte, IN

Works. The section farthest from Clear Lake is now a shopping

center. The three long buildings in the center have been

repurposed and are currently owned by Metaltec, Inc. and Berry Metals.

The building at the far right is gone.

The LaPorte Works built 338,000 All-Crop

Combines between 1935 and 1960. This combine eliminated the binder

and thresher pioneering the conversion to field harvesting.

The M50 Ontos Anti-Tank Gun: The

LaPorte Works did the final design for manufacturing, and was the sole

supplier for this tracked vehicle. The US Army contacted the LaPorte Works on October 26, 1951, to engineer and build the M50. On November 11,

1954, the Army ordered fifteen pilot models of the Ontos. In March

1955, after testing, the Army decided that the Ontos was not suitable for

use. But the Marines wanted the Ontos. They purchased the

first 29

in Fiscal Year 1956, and 267 in Fiscal Year 1957, for a total of

296. Subsequent orders brought the total up to 360.

Several M50s are on the assembly line at the

LaPorte Works.

This M50 Ontos is one of 14 still left, and

can be seen at Camp Atterbury in Edinburgh, IN. Used by

USMC in Vietnam, they were taken out of service by May 1969. It is

on display 190 miles from where it was built in northern Indiana.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

|