|

War

Production by Otis Elevator

Otis

Elevator in World War Two

Yonkers, NY

1852-1976

1976-Present as a subsidiary of United Technologies

This page added 6-18-2021.

I never had any intention of publishing a page

on the Otis Elevator Company of Yonkers, NY. It had not even

crossed my mind, as the company is not at all related to the American

Automobile Industry. However, as is the case with many of my pages,

fate would intervene, and I would learn how many different products Otis

Elevator made to help win World War Two.

On a return trip from Florida, I stopped in

Calhoun, GA to take several photos of a Pressed Steel M4A1 Sherman tank

at the National Guard Armory. I was aware that next door at the

American Legion there was also a 90mm anti-aircraft gun on display.

However, I was focused on the Sherman tank, not thinking the

anti-aircraft gun would produce anything new for me. How wrong

I was! On the gun was a data plate indicating that the recoil

mechanism was built by the Otis Elevator Company. It turns out

that Otis produced 3,961 or 50% of the recoil mechanisms for the 90mm anti-aircraft gun

during World War Two.

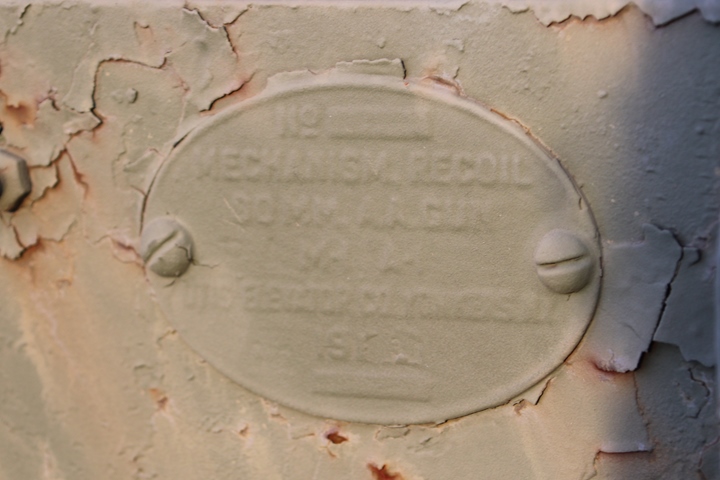

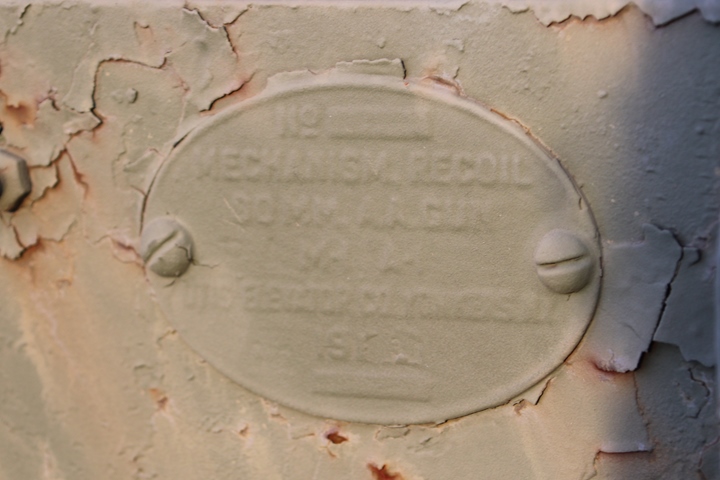

The data plate is difficult to read with

several coats of paint on it, but Otis Elevator built this recoil

mechanism for this M1A1 90mm anti-aircraft gun in 1943. Author's

photo.

It was early in the morning and the sun was just rising in Calhoun, GA.

Author's photo.

Author's photo.

Author's photo.

Upon my arrival home and things were

unpacked, I did an internet search on Otis Elevator in World War Two and

found the 107 page book "War Production by Otis." Upon its arrival

a week later, I was amazed by the amount of information contained in

this 1947 publication. It is one of the most comprehensive

publications I have found that details a company's contribution in

helping to win World War Two. This excellent account of how Otis

Elevator helped win World War Two is in the link at the top of the page.

Otis Elevator is known for its elevators and

escalators, found in many buildings in the United States. Like many

companies during World War Two, Otis produced large quantities of

military equipment totally unrelated to its normal peace-time product

line. Otis Elevator was prolific in both the variety and volume of products

it manufactured to help win World War Two. It stands

as an excellent example of how American industry rose to the occasion,

re-tooled its plants, and turned out the needed equipment to win World

War Two.

The

Aeronautical Division, Harrison, NJ won the Army-Navy "E" Award four times

during World War Two. The first award given on October 24, 1942.

The

Yonkers Works, Yonkers, NY won the Army-Navy "E" Award five times during

World War Two. The first was giving on August 15, 1942, and last on January 6, 1945.

The Otis Buffalo Works won the Army-Navy "E" Award four times during

World War Two.

Harrison Works Elevator Division, NJ won the Army-Navy "E" Award one time on July 10,1945.

Otis World War Two Products:

Aeronautical Division,

Harrison, NJ: This brand new

building was built for the manufacture of crankcases for the

Wright R-2600 radial engine. Construction began in February 1941 with

the first crankcases

shipped on October 11, 1941. Production demand for 2,500 crankcases

per month

required a second building erected at this location for machine tool

operations. This plant began producing parts on November 16, 1942.

The Otis Aeronautical Division began producing Wright R-3350 crankcases

for the B-29 in February 1945.

Yonkers Works,

Yonkers, NY: This plant

produced a variety of products for the war effort. This included: 3,961 90mm anti-aircraft gun recoil mechanisms, 78,710 navy electrical

bomb shackle release mechanisms, recoil mechanisms for 155mm cannons,

recoil mechanisms for 120mm anti-aircraft guns, Navy five-inch gun ammunition racks and

servers, C-46 tail landing gears, P-40 wing flap cylinder assemblies,

B-26 bomb hoists, B-26 engine hoists, and P-47 down lock cylinders.

Yonkers,

NY Aluminum Foundry:

The foundry produced castings for Otis-built products plus castings

other companies for B-17, F6F, PBM-5, C-46,

P-47, 1,486 machine tools, motors and generators, many for GE amplidynes , Sperry

searchlight trunnions,

Lawrance crankcases for US Navy, recoil mechanisms for 90mm

anti-aircraft guns, 155 long toms and 120mm anti aircraft guns, navy

five inch ammunition racks and servers, C-46 tail landing gear,

P-40 wing flap cylinder assembly, B-26 bomb hoists, B-26 engine

hoists, P-47 down lock cylinders, and 8,710 navy electrical bomb shackle release

mechanisms.

Harrison Works, Harrison, NJ: Elevator platforms and

ammunition hoists for navy cruisers, parts for 27,000 welding

generators, cradles for 4,000 for recoil mechanisms, assemblies for

torpedo hoisting equipment, parts of mine handling elevators and

mine layers, C-46 landing strut, PBM-3 and PBM-5 tail and top turrets,

87,000 shock mounts for aviation cameras and radios, 750 Morey 2-spindle

No.12 vertical profilers, large number of Morey turret lathes, Lawrance

Avilectric power plants for the B-17 and B-24 auxiliary generators, steam driven

pumps for Liberty ships, and P-47 cowl rings.

Buffalo Works, Buffalo, NY: Aircraft carrier aircraft

elevators, turret rings for Martin aircraft, PBM beaching gear, various

steel castings including 120mm anti-aircraft gun, various drop-forged

parts, and 37mm gun mounts for the Dutch Royal Navy.

Otis-Fensom Elevator Company, Hamilton, ONT:

5,000 40mm Bofors anti-aircraft guns, twin 40mm Bofors mounts for

Royal Canadian Navy and Royal Navy ships, truck-mounted 40mm Bofors

single mounts, 200 40mm Bofors mobile mounts, 30,000 40mm gun barrels,

8,000 40mm Bofors electrical-hydraulic fire control mechanisms, 76mm

muzzle brake for U.S. Army, 6-pounder gun mounts for the Ram tank, 40mm

Bofors elevating training mounts for U.S. Navy, light-weight ammunition

trailers, engine lathes, bombing teaching assemblies, 20mm mobile quad

mount sub-assemblies, Lancaster and Lincoln tail wheel assemblies,

Mosquito 20mm gun mounts, radar rotator assemblies, various castings

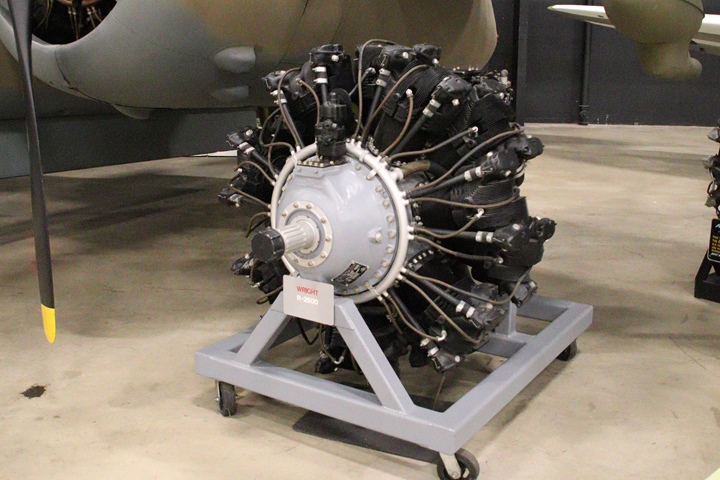

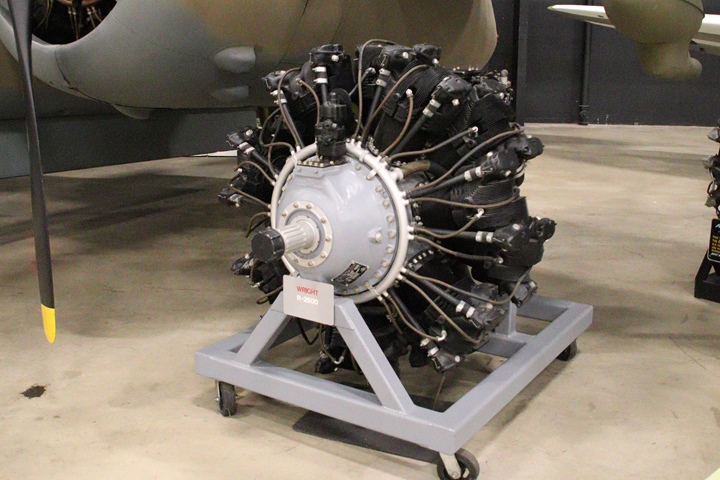

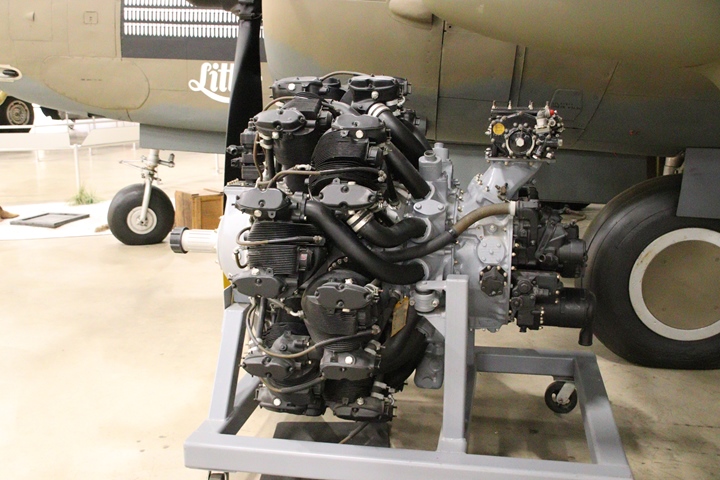

Aeronautical Division,

Harrison, NJ Product Photos:

This cut-away of an R-2600 is on display at

the National Museum of the United States Air Force. The outline of

the crankcase is painted in red on this example. Assuming Otis

Harrison, NJ plant came to full production of 2,500 crankcases per month

in October 1942, the company built at least 90,000 R-2600 crankcase

during the war. Author's photo.

The North American B-25 had R-2600 engines.

Author's photo.

The U.S. Navy's Curtiss SB2C was powered by

the Wright R-2800 with Otis-manufactured crankcases. Author's

photo.

The R-2600 was the power plant for the

General Motors Eastern Aircraft Division's TBM Avenger torpedo aircraft.

Author's photo.

The Douglas A-20 attack aircraft used two

R-2600 engines with Otis crankcases. This A-20 is on display at

the National Museum of the United States Air Force. Author's

photo.

This R-2600 engine is on display next to the

A-20. Author's photo.

Author's photo.

This diorama shows the R-2600 installed on

the A-20 with part of the engine cowling removed. Author's photo.

The early versions of the Martin PBM were

powered by R-2600 engines. The Otis Harrison Works produced top

and rear gun turrets for the PBM-3 and PBM-5 aircraft. Author's

photo.

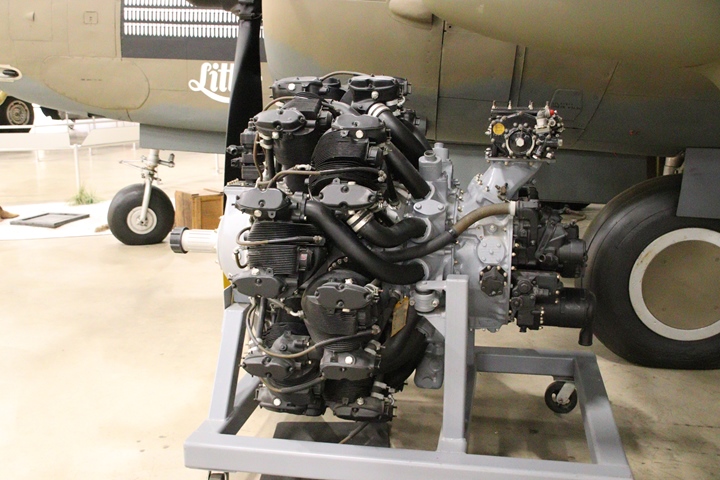

In early 1944 Otis began tooling up to

manufacture the Wright R-3300 crankcase which powered the B-29.

First delivery of the engine was in February 1945. Author's photo.

This is only one of two B-29s still flying.

It may well have Otis-built crank cases in the R-2250 engines. Author's photo.

Yonkers Works, Yonkers, NY Product Photos:

This 90mm anti-aircraft gun on display at

the Indiana Military Museum in Vincennes, IN is equipped with an Otis

recoil mechanism. Otis built 3,961 of the 7,831 recoil mechanisms

required during World War Two. This was 50% of the total.

Author's photo.

The Otis Elevator recoil mechanism is serial

number 6848 and was built in 1943. Author's photo.

Otis produced recoil mechanisms for the 550 120mm M-1 anti-aircraft guns

produced at the Fisher Body Division of General Motors Grand Rapids, MI

plant. Author's photo.

The Otis Elevator Company in Yonkers, NY also built recoil mechanisms

for the 155mm "Long Tom" cannon. Author's photo.

This five-inch, 38 caliber gun can be

seen at the USS Sullivans at the Buffalo and Erie County Naval and

Military Park in Buffalo, NY. The ammunition for the five inch

guns was fed into the gun turret from below deck. Otis Elevator's

Yonkers' plant provided the ammunition racks and servers to keep these

rapid firing weapons provided with ammunition. Author's photo.

The Yonkers Works produced Curtiss P-40 wing flap cylinder assemblies.

Author's photo.

Both the Otis Yonkers and Harrison Works

produced landing gear components for the Curtiss C-46. This C-46

is on display at the National Museum of the United States Air Force.

Author's photo.

Yonkers produced the tail landing gear.

Author's photo.

Both the

Otis Yonkers and Harrison Works produced components for the Republic

P-47. Yonkers manufactured the down lock cylinders for the landing

gear. Author's photo.

Curtiss, Eastern Aircraft, Martin, Republic,

and Wright were all located on the east coast. This made

Otis Elevator Company an excellent choice for supplying components for

these aeronautical companies.

Yonkers,

NY Aluminum Foundry Product Photos:

Grumman Aircraft on Long Island, NY was

another east coast aircraft company for which Otis supplied parts. The

Yonkers Foundry cast parts for the Grumman F6F fighter. Author's

photo.

The Yonkers foundry cast components for the

B-17 bomber. Unlike the other parts Otis built for different

aircraft, the B-17 was not built on the east coast of the United States.

It was built in Washington and California. Author's photo.

The Yonkers foundry cast the trunnions for

the Sperry searchlight. The trunnion is the U-shaped device.

Author's photo.

Harrison Works, NJ Product Photos:

Harrison Works produced the landing gear

strut for the Curtiss C-46. This is the strut for the starboard

landing gear on the C-46 shown above. Author's photo.

Author's photo.

This photo of the port C-46 landing gear

shows the strut up inside of the landing gear doors. Author's

photo.

The Harrison Works produced

cowl rings for the P-47. These opened and closed to keep the

engine at the proper operating temperature. Author's photo.

The Harrison Works manufactured 87,000 radio

shock mounts for the Army Air Force like these in the radio room of a

B-17. Author's photo.

Otis-Fensom Elevator Company, Hamilton, ONT

Product Photos:

Otis-Fensom built 40mm Bofors twin-mounts

like this one for the Royal and Royal Canadian Navies. Author's

photo.

Otis-Fensom also mounted 40mm Bofors on Ford

of Canada Canadian Military Pattern trucks.

Author's photo.

Author's photo.

When the 76mm main gun began its use in combat after D-Day in Europe, it

was found by the armored vehicle crews that the weapon's blast created a

lot of dust that obscured the gunner's view for follow-up shots.

The original 76mm main guns did not have muzzle brakes that would help

alleviate this problem. The U.S. Army contracted with Otis-Fensom

in Canada to manufacture muzzle brakes on an expedited basis for

shipment to the battle zone. The Buick-built M18 Hellcat tank

destroyer was one of the weapons with the new 76mm main gun.

Author's photo.

The M4A3 Sherman tanks equipped with the

76mm main gun also required muzzle brakes.

Author's photo.

Author's photo.

Otis-Fensom also built for the Canadian army

mobile quad 20mm gun mounts on two wheel trailers.

Author's photo.

De Havilland Mosquito KA 114 is one of 1,032

of this type built by De Havilland during the Second World War at its Downsview

plant in Toronto, Ontario not far from the Otis-Fensom plant in

Hamilton, ONT. Otis-Fensom built 30mm gun mounts for the aircraft

Author's photo.

Otis-Fensom built tail wheel struts for the

Lancaster bomber.

Author's photo.

|