|

Chrysler Kokomo Transmission Plant During World War Two

Kokomo, IN

1937- Current

This page updated 4-5-2023.

With the 1925 demise of the Haynes

Automobile Company in Kokomo, IN, its former plant on Home Avenue lay

dormant. In 1937, Chrysler purchased the plant and began

manufacturing transmissions for its vehicles. Chrysler occupied

the former Haynes factory until it built a new transmission plant in

1955, on a 154 acre site a mile southeast of the Haynes facility.

Chrysler then utilized the former Haynes factory as an aluminum die

casting plant. Chrysler is still a major employer within the Kokomo

area.

This view of the Chrysler manual

transmission plant on Home Avenue is looking northwest. Home

Avenue is in the foreground.

As of March 2023, the plant which housed the

former Haynes Automobile Company and later Chrysler transmission

operation stands empty.

The last known occupant was an automotive recycling company. While

looking a little ragged due to lack of attention, this 100 year old plant still

stands proud. This is one of several plants in Kokomo, IN that

helped win World War Two. Author's photo.

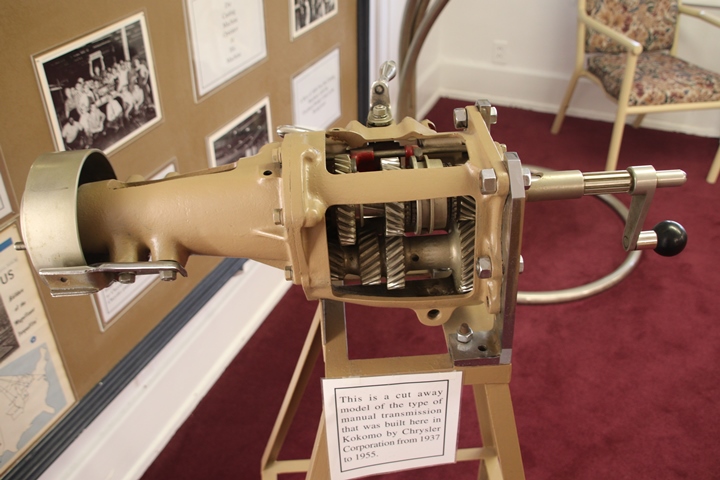

Between 1937 and 1955, the Chrysler Home

Avenue plant produced 5,124,211 manual transmissions, just like this one

on display at the Elwood Haynes Museum in Kokomo, IN. Author's

photo.

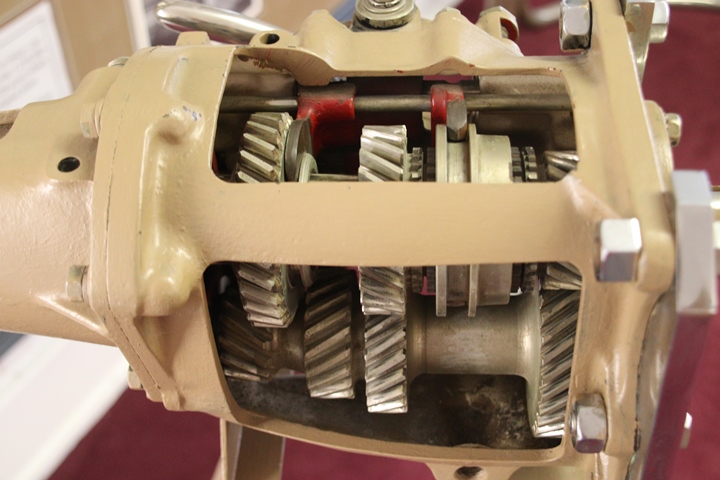

The display is set up so visitors can turn

the crank and watch the gears as they mesh inside the transmission.

Author's photo.

This image shows the Kokomo plant had the

capability to make and cut gears. This capability was put to use

during World War Two. Author's photo.

Chrysler Kokomo Plant World War Two

Products: Information is limited on how the Chrysler Kokomo

plant helped win

World War Two. An informational placard at the Elwood

Haynes Museum notes that the plant made "parts for tanks and Bofors

guns." The "War Industrial Facilities: Authorized July 1940

- August 1945" published by the Civilian Production Administration on

July 30, 1946, shows that the plant made "Gear Boxes." Gear box is

another term for transmission. Therefore, the tank parts the

Kokomo plant made were, most likely, gears and transmissions for the M3

Grant/Lee and M4 Sherman series medium tanks that Chrysler built in

Warren, MI. Army Ordnance provided $247,000 in capital funding for

the Kokomo plant for tooling to make the gear boxes.

This is a transmission from an M4A2 Sherman

tank display at the Canadian War Museum in Ottawa, Ontario, Canada.

This is very similar in construction to the civilian manual

transmissions made by the Kokomo plant. Conversion of the plant

to make and assemble the gears into a tank transmission would have

been rather straight forward. The driver's seat can be seen in the

background. Author's photo.

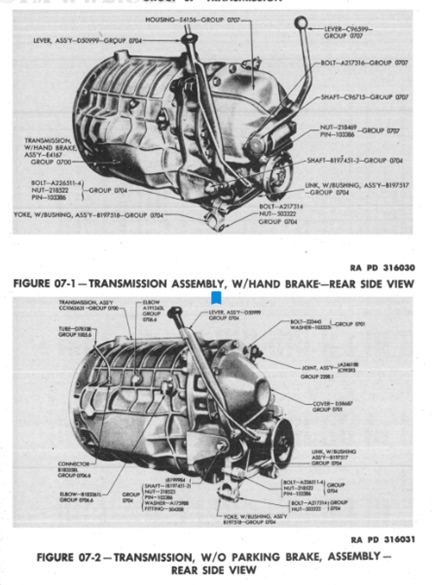

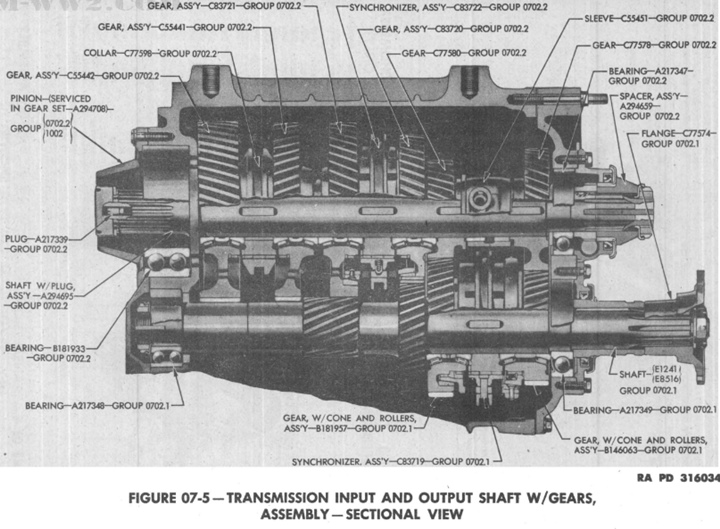

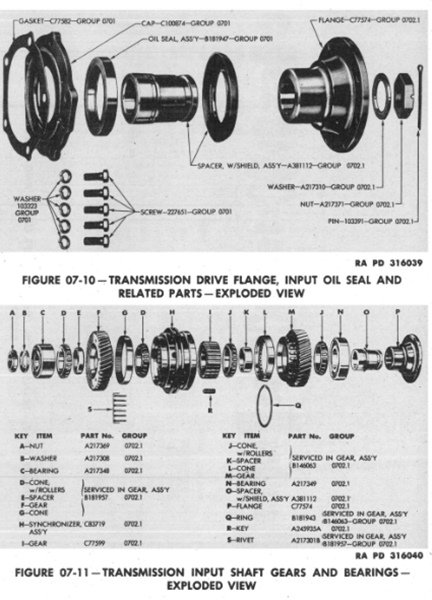

This and the next four images provide

detailed information on a typical Sherman tank transmission. There

were a lot of parts that went into the construction of this transmission

for the Chrysler Kokomo plant to have made for the war effort.

Image added 4-5-2023.

Image added 4-5-2023.

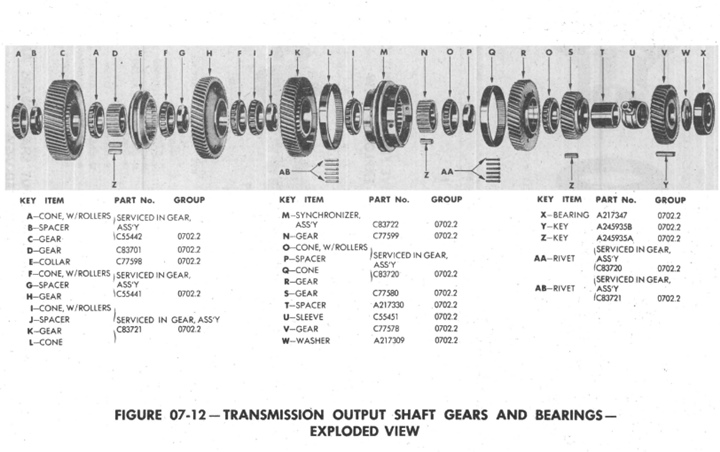

This and the next image show two of the

several different subassemblies in the transmission. Image added

4-5-2023.

Image added 4-5-2023.

The transmission shown above is in this

cut-away of a Fisher Body-built M4A2 Sherman tank. Several

different companies built Sherman tanks powered by different engines,

but items like the transmission were standardized

for ease of production. Author's photo.

This is the differential on the Sherman

tank. The transmission mounted inside the tank connects directly

to the differential on the front of the tank. The Kokomo plant

could also have been making many of the gears for this assembly.

Author's photo.

Author's photo.

The M4 Sherman tank was

not the first tanks built by Chrysler in Warren, MI. The M3

Grant/Lee tank began production in July 1941. Table 1

shows the monthly production of the M3 series tanks and how many

transmissions per month Kokomo provided. The M3 and M4 tanks

used the same transmissions.

|

Table 1 - Chrysler M3 and M3A4 World War Two Production |

| |

Jul

41 |

Aug

41 |

Sep

41 |

Oct

41 |

Nov

41 |

Dec

41 |

Jan

42 |

Feb

42 |

Mar

42 |

Apr

42 |

May

42 |

Jun

42 |

Jul

42 |

Aug

42 |

Totals |

| M3 |

7 |

50 |

95 |

148 |

194 |

235 |

300 |

300 |

366 |

381 |

400 |

424 |

317 |

28 |

3,243 |

|

M3A4 |

|

|

|

|

|

|

|

|

|

|

|

33 |

73 |

3 |

109 |

|

Totals |

7 |

50 |

95 |

148 |

194 |

235 |

300 |

300 |

366 |

381 |

400 |

457 |

390 |

31 |

3,352 |

This M3 tank was built in July 1942.

Author's photo.

|

Warren, MI

Chrysler

Tank Arsenal

Production during World War Two |

| Type |

Number built |

Dates |

Engines |

| M4A4

(75) Sherman |

7,499 |

7-1942 to 9-1943 |

Chrysler multi bank.

See M4A4 and engine photos below. |

| M4A6

(75) Sherman |

75

|

10-1943 to

3-1944 |

Caterpillar

diesel radial |

| M4(105) Sherman |

1,641 |

2-1944 to

3-1945 |

Continental

built Wright R975 radial aircraft |

| M4A3(105)

Sherman |

3,039 |

5-1944 to 6-1945 |

Ford GAA V8 |

| M4A3(76) |

4,017 |

3-1944 to 4-1945 |

Ford GAA V8 |

| M4 Composite Sherman

(75) |

1,676 |

8-1943 to 1-1944 |

Continental

built Wright R975 radial aircraft |

| Total M4 Series

|

17,947 |

|

|

Different versions of Sherman tanks not only

had different engines, but the main gun armament was also different on

them. Main gun armament included 75mm and 76mm guns and 105mm

howitzers.

This 4A3E8 is armed with a 75mm cannon.

Author's photo.

This 4A4E8 is armed with a 75mm cannon.

Author's photo.

This 4A3E8 is armed with a 76mm cannon. Author's photo.

This 4A3E8 is armed with a 105mm

howitzer. Author's photo.

40mm Bofors Anti-Aircraft Gun Parts:

It is unknown which 40mm Bofors gun components were produced at the

Kokomo plant for the. Kokomo was one of twelve Chrysler plants that made

parts for final assembly at the Plymouth plant in Detroit, MI. The

Plymouth plant produced 14,442 pairs of Bofors guns for the U.S. Navy

and 30,095 single Bofors guns for the U.S. Army.

Chrysler built 14,442 Dual 40mm water cooled Bofors Guns for the US Navy

under license from the Bofors Company of Sweden during World War Two. After

Chrysler engineers set up the manufacturing and assembly based on mass

production techniques, the weapon could be assembled in ten

hours. Bofors in Sweden was taking 450 hours to assemble a weapon.

Chrysler only produced the barrels and the

breech section of the weapon. The gun mounts were provided by

other companies.

Chrysler also built 30,095 Single 40mm air cooled Bofors Guns for the U.S.

Army. This was 86% of all of the Bofors built for the U.S. Army.

As with the Bofors for the U.S. Navy, Chrysler only manufactured and

assembled the firing portion of the weapon. The carriages were

built by other companies. For the weapon shown here, Chrysler

shipped the finished barrel and breech assemblies to the Firestone Tire

and Rubber Company in Akron, OH. Firestone then mounted the gun

assembly on its carriages.

Post World War Two Era: The Home Avenue plant returned to

making civilian vehicle transmissions after World War Two and continued

to do so until 1955 when a new plant was built a mile

southeast of the Home Avenue plant for the production of the new

three-speed TorqueFlite automatic transmission. Home Avenue became

a die casting plant and operated until 1969 when a new casting plant was

built in Kokomo.

This chrome plated TorqueFlite transmission

is on display at the Elwood Haynes Museum in Kokomo, IN. Author's

photo.

This image shows the new TorqueFlite

transmission plant under construction in 1945. Even before it was

completed, production of the transmission began. In the background

is the original U.S. 31 Kokomo by-pass. However, there were no

restrictions on access to the highway. Kokomo became known as the "stop

light city" for any travelers attempting to go north or south through

the city. The state highway department learned its lesson, so when

it put in a new U.S. 31 by-pass east of Kokomo, it came with limited

access. The field to the east of U.S. 31 in the photo later became

the main production area for Delco Electronics. Unlike the

transmission plant, the Delco Electronic facility is mostly vacant.

Author's photo from the Elwood Haynes Museum.

This image is looking southwest with the

original U.S. 31 by-pass in the foreground. The new casting plant that was built in 1969

is in the upper right.

|