|

Laister-Kauffman

Aircraft Corporation in World War Two

St. Louis, MO

1941-1946

This page added 11-6-2022.

As World War Two approached and the United

States military learned of the success of German airborne glider attacks

in May 1940 during the invasion of Belgium, there was an urgent need for

gliders in the United States. As the United States Army Glider

Program began taking shape, 27 year-old Jack Laister, a well-known

civilian glider designer since he was 14 years old, modified his 1938

Yankee Doodle single seat glider by adding a second seat. This

then became the TG-4A series of gliders that the Laister-Kauffman

company built for the U.S. Army. However, while Mr. Laister had

the design, he did not have the financing for their manufacture.

He was able to partner with St. Louis businessman John Kauffman and the

Laister-Kauffman Aircraft Corporation was born. The company came

into existence because of the need of gliders for World War Two, and

when the war ended, and production ceased in August 1945, the need for

gliders came to an abrupt end. There would be no further use for

military gliders as the age of the helicopter was beginning.

Laister-Kauffman was not fully reimbursed by the United States

government for materials it had purchased for future production, and the

company filed for reorganization under Chapter 10 of the

bankruptcy codes in September 1946. In the end, the company went

out of business. Note: A special thank you to Mr. Jim

Moffett for information on the end of the company.

Laister-Kauffman Aircraft Corporation World

War Two Production: The company had $23,075,000 in major

contracts during World War Two. For a company that did not exist

until 1941, this is an amazing amount. The demand for both

training gliders and combat gliders was of extreme urgency during the

war, as the United States Army Air Forces was playing catch-up with the

Germans. Laister-Kauffman built the TG-4A training glider and

CG-4A combat glider.

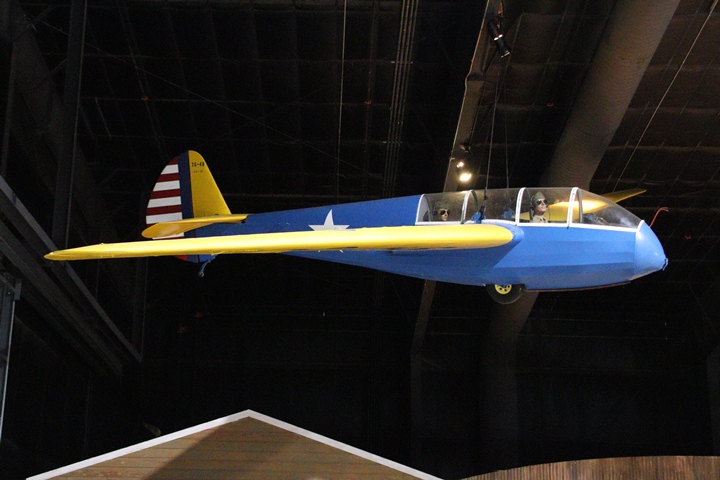

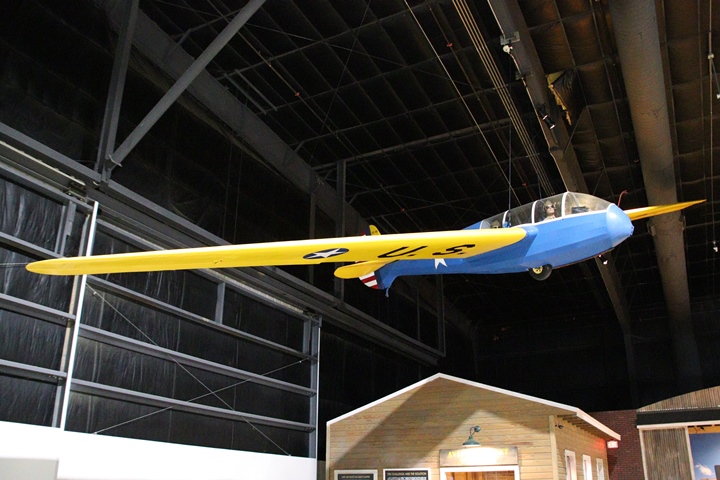

This TG-4A is on display at the Museum of

Aviation at Robbins Air Force Base, GA. While photographing the glider

during my visit to the museum, I decided to research the company and

publish this page to recognize the company's contribution to winning

World War Two. Table 2 shows that there were 150 production and

three experimental versions of this type built. These were used to

train pilots in preparation to flying the CG-4A combat glider. Author's photo.

Table 2 shows that the company built 230

CG-4A combat gliders under license from the Waco Aircraft Corporation of

Troy, OH. Author's photo.

Laister-Kauffman did not have a factory and

assembled all of its gliders in the St. Louis Arena. The St. Louis

Arena opened in 1929 and was the home of the St. Louis Blues hockey team

among many other hockey and basketball teams until it closed in 1994.

It was imploded on February 27, 1999, the day this photo was taken.

The Laister-Kauffman Aviation Corporation did

not have time to build a factory. The Army Air Forces wanted its

gliders yesterday, not today. During the war, professional sports

came to a standstill and no doubt Mr. Kauffman had the proper

connections to be able to quickly occupy this space to not only build

gliders but create jobs in St. Louis.

In this photo, workers are working on the rib

and wing assembly for the TG-4A glider.

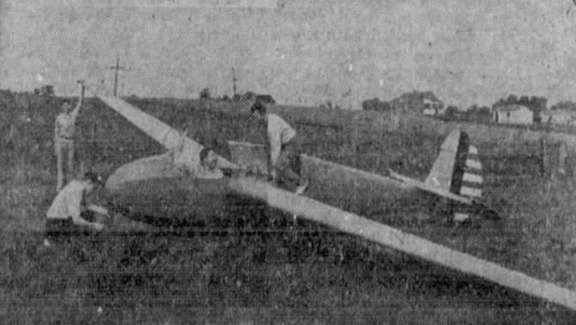

A TG-4A is shown being assembled by five

workers inside the St. Louis Arena.

Laister-Kauffman workers are shown here doping

down a wing and adding the star and bar insignia for a DG-4A.

Final assembly of the wings may have taken

place at a suitable field to test the gliders before acceptance by the

Army Air Forces.

Table 1 - Laister-Kauffman

Aircraft Corporation's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Gliders - USAAF |

$6,155,000 |

3-1942 |

1-1943 |

| Gliders - USAAF |

$302,000 |

3-1942 |

4-1943 |

| Gliders - USAAF |

$856,000 |

4-1942 |

9-1944 |

| Gliders - USAAF |

$301,000 |

5-1942 |

7-4193 |

| Glider Noses

- USAAF |

$267,000 |

6-1944 |

9-1944 |

| Glider Repair

Servs - USAAF |

$1,791,000 |

7-1944 |

2-1945 |

| Gliders - USAAF |

$2,071,000 |

10-1944 |

8-1945 |

| Gliders

CG-10A - USAAF |

$11,255,000 |

3-1945 |

3-1946 |

| Metal Booms -

USAAF |

$77,000 |

6-1945 |

12-1945 |

| Total |

$23,075,000 |

|

|

|

Table 2 - Laister-Kauffman

Aircraft Corporation's World War Two Glider Production |

|

U.S. Army Air Force Serial Numbers |

Type |

Quantity Built |

Comments |

| 42-61099

through 42-61100 |

XCG-10A-LK |

2 |

Laister-Kauffman

Aircraft Corporation Model LK-11B Trojan Horse 42 seat

glider. |

| 42-53022

through 42-53096 |

TG-4A-LK |

75 |

Laister-Kauffman

Aircraft Corporation LK-10A Yankee Doodle 2 tandem seat

training glider. |

| 42-53525

through 42-53526 |

XCG-10A-LK |

2 |

Laister-Kauffman

Aircraft Corporation Model LK-11B Trojan Horse 30 seat

gliders ordered April 22, 1942.

42-53525 accepted October 4, 1942. First flight

November 6, 1943. Converted to 42 seat glider.

42-53525 completed as a 42 seat glider. |

|

42-43649through 42-43678 |

CG-4A LK |

30 |

Laister-Kauffman

Aircraft Corporation Model NZR troop glider. Built

under license from the Waco Aircraft Company, Troy, OH. |

|

42-4367through 42-43753 |

TG-4A-LK |

75 |

Laister-Kauffman Aircraft Corporation LK-10A Yankee Doodle 2

tandem seat training glider. |

|

42-14705-hrough 42-14707 |

XTG-4-LK |

3 |

Laister-Kauffman

Aircraft Corporation |

| 43-42129

through 43-42228 |

CG-4A-LK |

100 |

Laister-Kauffman

Aircraft Corporation LK-10A Yankee Doodle 2 tandem seat

training glider. |

| 45-17143

through 45-17242 |

CG-4A-LK |

100 |

Laister-Kauffman

Aircraft Corporation LK-10A Yankee Doodle 2 tandem seat

training glider. |

| 45-44450

through 45-44459 |

YCG-10A |

|

Laister-Kauffman

Aircraft Corporation Model LK-11B Trojan Horse 42 seat

glider. All ten units were cancelled |

| 45-44460

through 45-454499 |

CG-10A |

|

Laister-Kauffman

Aircraft Corporation Model LK-11B Trojan Horse 42 seat

glider. 1,040 units cancelled. |

| Total |

|

387 |

|

Table 1 shows that

Laister-Kauffman was awarded a $11,255,000 contract in March 1945 for CG-10A

gliders. Table 2 shows that only four experimental XCG-10A-LK 42 seat combat gliders

were built. Table 2 also shows that ten YCG-10A test gliders and 1,040 CG-10A

production gliders were cancelled and most of the $11,255,000 was never

spent. The CG-10A was the largest American glider built during

World War Two. This was a quantum jump for a company that only

began business in 1941, but it also shows the engineering and design

ability of Jack Laister.

On August 3, 1945, it was announced in

Louisville, KY that the Laister-Kauffman Aviation Corporation was

taking over the Louisville Defense Plant at the Louisville Airport.

Previously, this plant had been occupied by the Curtiss-Wright

Corporation to build 458 C-46 twin-engine cargo aircraft. It

had fulfilled its contract with the Army Air Forces and the plant

was turned back over to the Defense Plant Corporation, which then

leased it out to the Laister-Kauffman Aviation Corporation. It

was the ideal venue in which to build the CG-10A gliders which was

basically the same size as a C-46. Employment figures were

expected to reach 1,000 employees as the large cargo gliders were

urgently needed for the upcoming invasion of Japan.

Then on August 6 and August 9, 1945

top-secret atomic bombs were dropped on Japan. On August 15,

1945, Japan surrendered. Wartime contracts were cancelled on a mass basis as there was no longer a need for more equipment.

No production CG-10A cargo gliders were ever built in Louisville,

KY.

This is USAAF serial number 42-61100

which was the second Laister-Kauffman glider to be assigned a

number.

The CG-10A had rear opening clam shell

doors which allowed for easy exit of small vehicles, artillery, and

42 troops.

Laister-Kauffman TG-4A Gliders on Museum

Display:

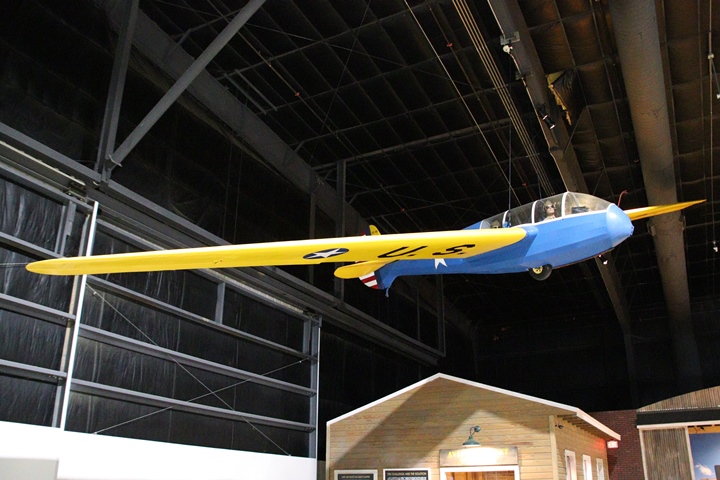

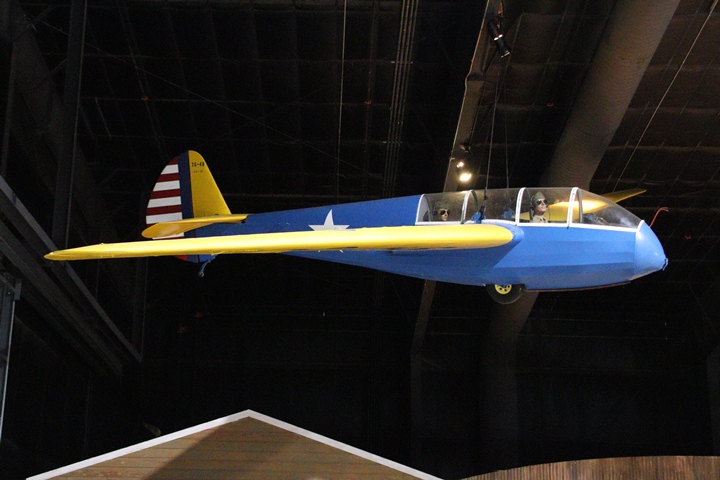

Here are four more photos showing the TG-4A

on display at the Museum of Aviation at Robbins Air Force Base, GA. The aircraft is located in the Museum's World War Two hangar.

Author's photo.

Author's photo.

The fuselage was constructed of fabric on a welded

steel frame. The tail was made of wood with a fabric covering

while the wings were made of wood. The first one-third of the wing's

leading edge was covered with plywood and the entire wing covered in

fabric. The aircraft had a 22:1 glide ratio. Author's photo.

This is serial number 42-43740. Author's photo.

Author's photo.

This is rather embarrassing. I have walked underneath this TG-4A

dozens of times at the National Museum of the United States Air Force

since it was placed on display in 2003 and never paid any attention to

it. It was only when I began work on this page that I realized the

Museum had this TG-4A on display. However, with over 350 aircraft

on display at the museum, it is not difficult to overlook an aircraft or

two. Author's photo.

This is serial number 42-43734. Author's photo.

This TG-4A is on display in the World War

Two room of the Air Zoo Aerospace & Science Museum in Kalamazoo, MI.

For the photos of this TG-4A, I made a special trip accompanied by my

oldest grandson. It was his first visit to this excellent museum. Author's photo.

This aircraft is Laister-Kauffman serial

number 92 and was registered as N58189 until de-registered May 2015 when

it was brought to the museum for display. Author's photo.

Author's photo.

Author's photo.

Author's photo.

This

1943 Laister-Kauffman TG-4A is company serial number 126 and USAAF

serial number 42-53072. It is on display at the Military Aviation Museum

in Virginia Beach, VA. Author's photo.

The glider still carries the registration

number N51462 which is good through March 2024. Author's photo.

Laister-Kauffman-built TG-4A is company

serial 139. One source gives this as USAAF serial number

42-530727. This is most likely 42-53727. Author's photo.

Author's photo.

|