|

Other Lansing Companies that contributed

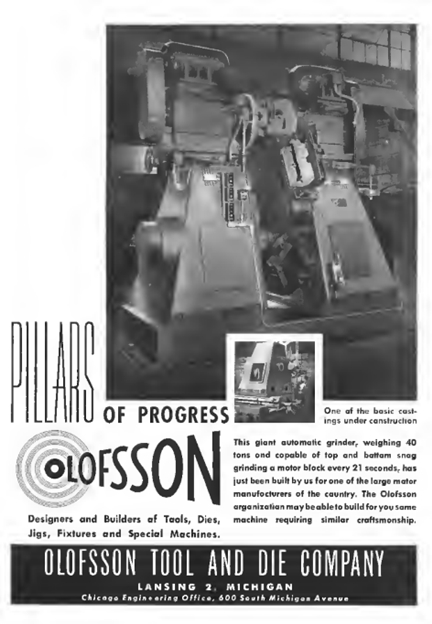

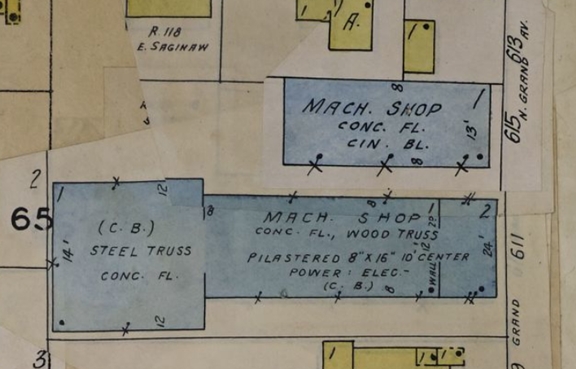

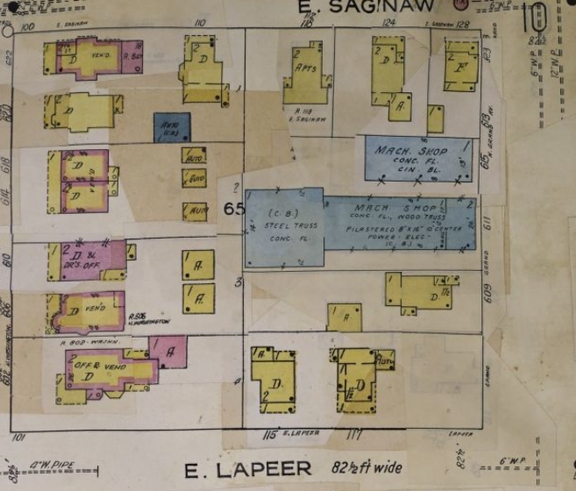

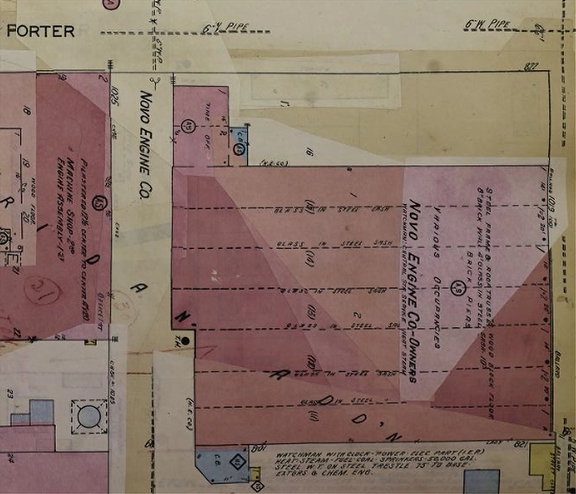

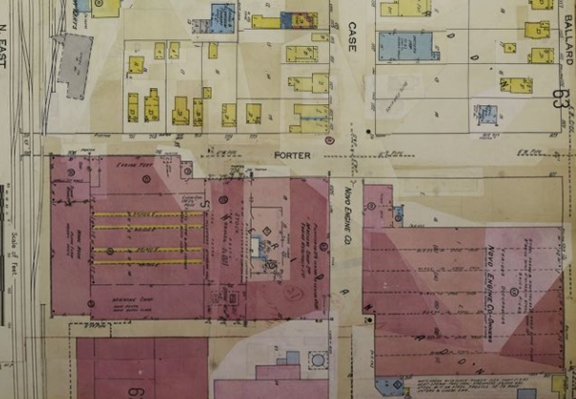

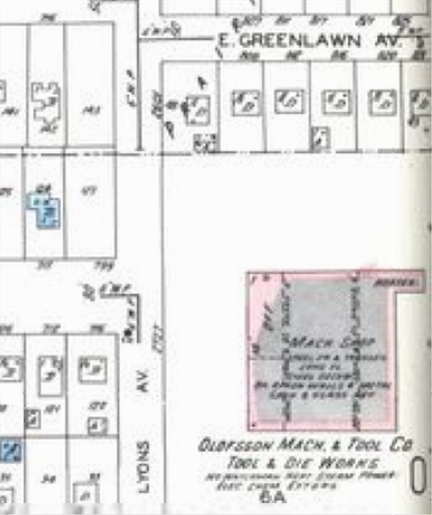

to winning World War Two This page added 9-8-2022. In 1935, George Alex Olofsson began what become the Olofsson Tool and Die Company in a small building at 611 North Grand Avenue in Lansing, MI. Using several pieces of leased machine tools, he was the proverbial "Mom and Pop" operation without the "Mom," as he was a one person operation. The machine tools were from Capital Tool and Engineering of Lansing, and over the next several years he also purchased machine tools as the cash became available. In 1939, the president of Capital Tool and Engineering retired, and Mr. Olofsson purchased the company and renamed it Olofsson Tool and Die Company. With the added equipment, he moved some of the new equipment to a larger facility that he rented from the Novo Engine Company at 738 Porter Street. At this time, the company had expanded to 30 workers. The new company operated out of these two buildings until the company moved into a new facility on the south side of Lansing in November 1946. The 22 acre site that the company purchased from an estate was located at 2727 South Lyon Avenue. At this time, the company employed 135 persons. Also at the time, the company began to also focus on machine tools along with the tool and die business. Its customer base included the automobile industry in Lansing and southeast Michigan. It also had customers in the appliance, railroad, and farm industries. Olofsson Tool and Die Company was family owned until it was sold to the John Brown Company of Coventry, England on January 31, 1982. Three years later in December 1985, the John Brown Company sold Olofsson Tool and Die Company to a group of Michigan investors, named Cordier Enterprises, for $21.2 million. When Cordier Enterprises purchased Olofsson, it also applied to the State of Michigan for a bond issue to fund new equipment and renovations within in the plant. This may have been a sign that the John Brown Company had not kept the plant up-to-date with the latest technology before selling it. In 1996 Precision Castparts purchased Olofsson Tool and Die, but then shut it down on Friday September 27, 2002, putting 70 persons out of work. The reason given for the closure was the poor business outlook in the tool and die industry. After 65 years, Olofsson Tool and Die no longer existed. Olofsson Tool and Die in World War Two: In November 1942, the company was the first in Lansing to win the U.S. Treasury Department's "Bullseye" award for having over 90% of the company's employees deducting more than 10% of their pay for war bonds. During World War Two the company had at peak 260 employees working on war projects. The only products that is known that the company made were parts for radar equipment. Below are two advertisements the company ran in 1944 and 1945 in aviation industry magazines demonstrating its capabilities to help win World War Two.

Oldsmobile, The Reo Motor Car Company, and Motor Wheel of Lansing were all customers of Olofsson during peacetime that would also use the company during the war when tooling needed to be built in a hurry to meet the needs of the military.

Therefore, some of the products that Olofsson

could have been making tools, dies, and machined parts for were: The Reo Motor Car Company: Military truck and Navy bomb fuzes Motor Wheel Corporation: Military truck wheels and brake drums, shells, and rockets The Nash-Kelvinator Company, which was not a native Lansing company, set up operations during the war to make aircraft propellers. It would have needed a company like Olofsson to provide many of the tools and dies needed to manufacture the propellers. No doubt, the Olofsson had dozens, if not over a hundred, customers during World War Two. The Plants: Below are Sanborn fire insurance maps and current Google Maps to show the different locations of the Olofsson Tool and Die Company.

|