|

Blood

Brothers Machine Company in World War Two

Allegan, MI

1914-1987

This page updated 10-15-2023.

In September 2022, I was at the Wheels of

Liberation collection of military vehicles in Gettysburg, PA

photographing this Four Wheel Drive Auto Company's HAR-1. It had

just returned from the bead blaster and had not yet been reassembled.

This allowed me to photograph parts of the truck and many of its

components to which one does not normally have access. Author's

photo.

While photographing this portion of the

drivetrain, I noticed a tag with some writing on the universal joint.

Author's photo.

The information on the universal joint says it

was made by the Blood Brothers Machine Company of Allegan, MI, which is

a company name I had not seen before. All of the universal joints on the HAR-1 were provided by

the Blood Brothers. Author's photo.

At the turn of the 20th

Century, the Blood Brothers began making bicycles in Kalamazoo, MI.

In 1914, the brothers purchased a factory in Allegan, MI, and began

making race cars with their own unique chain drive. The

Cornelian race car was driven by Louis Chevrolet in the 1915

Indianapolis 500. Mr. Chevrolet had to drop out due to engine

valve failure but did place 20th in the event.

As I began to investigate the

Blood Brothers Machine Company in earnest at the Allegan Area Chamber of

Commerce website, I noted that the Chamber was selling Blood Brothers

Christmas ornaments. While the Rockwell International plant that

was its descendent had closed thirty years earlier, the Chamber still

remembered the Blood Brothers Machine Company by selling Christmas

ornaments. This told me that the former company had a large impact

on the town.

In 1900, Maurice, Clarence, and Charles

Blood began producing bicycles in Kalamazoo, MI. In 1914, the

brothers purchased this former glass factory in Allegan, MI in which to

build their cars. Production of the Cornelian automobile as a

non-race car began in 1914 and ended in September 1915 when only 100 were sold. At this point,

the company began manufacturing universal joints for the automobile

and farm implement industries.

In 1936, due to financial difficulties, the

Blood Brothers Machine Company became a wholly owned subsidiary of the

Standard Steel Spring Company of Coraopolis, PA. Then in 1975 the

ownership of the company became the property of Rockwell International,

a large conglomerate of the era.

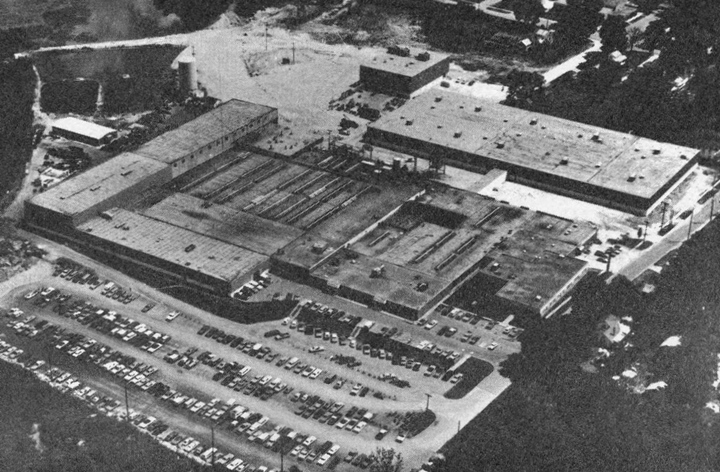

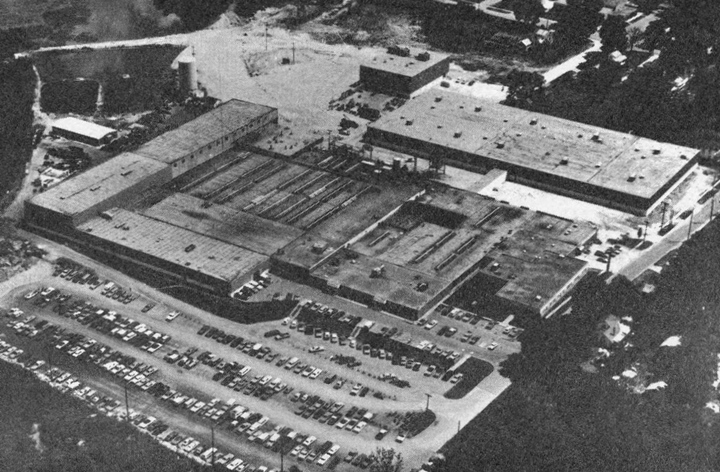

By 1979, the facility had expanded to the

plant size shown here that totaled 343,000 square feet of floor space on

31 acres. The operation employed 750 workers. But it would

not last. Rockwell's share of the drivetrain business began to

fall off, and in 1987, it closed the plant. This occurred after

another Rockwell facility in Iowa was chosen to carry on with the

production from both plants, when the union in Iowa voted to take wage

concessions and the State of Iowa gave Rockwell a $1.4 million grant.

However, to get the grant, the State of Iowa stipulated that Rockwell

had to close other plants making the same product. Therefore, in

1987, the plant shown here was closed.

This was a disaster for Allegan, MI.

Currently, Allegan, MI has a population of just over 5,200 persons.

To lose a factory that provided jobs for over 10% of the population of

the town was severe and traumatic for the workers, their families, and

the citizens of the area. It is no wonder that 40 years later the

Chamber of Commerce produced a Blood Brothers Machine Company Christmas

Ornament. The company started by the Blood Brothers in 1914 had

become a mainstay of Allegan, MI.

Now for the kicker in the rest of the story.

The Iowa plant only lasted about ten years. Rockwell took the

State of Iowa's money and then also closed that plant.

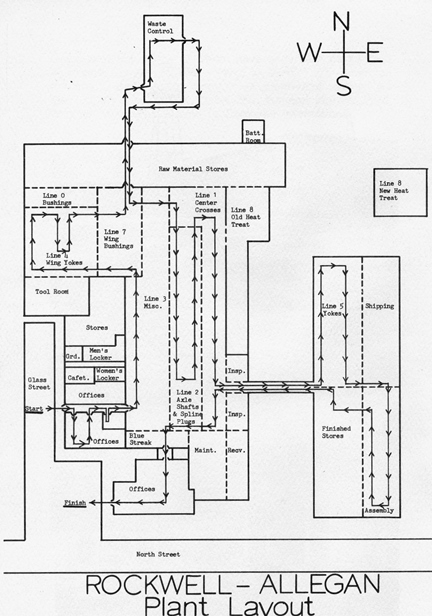

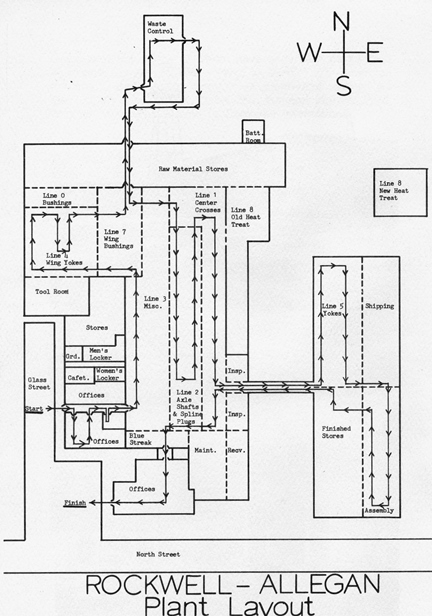

This shows the layout of the facility in the

mid-1970s.

I see this all too often. Where a

factory once stood is now empty space. However, the former drive

shaft final assembly plant has been repurposed with a new occupant.

Image courtesy of Google Maps.

Image courtesy of Google Maps.

This 1926 Acme Model 125 five-ton truck is

on display at the National Auto and Truck Museum in Auburn, IN.

The information placard in front of the truck notes that it came

equipped with Blood Brothers universal joints. Author's photo.

I had looked at this truck and read

the information on it several times during past visits. However,

on my December 2022 trip to the museum, the name Blood Brothers now

meant something to me. I had to see if it still had Blood Brothers

universal joints installed. Therefore, for the next few minutes I

was underneath the truck photographing universal joints. Author's

photo.

Both universal joints on this truck were

made by the Blood Brothers of Allegan, MI. Author's photo.

This photo of the underside of the rear

universal most plainly shows the company's name and location.

Other end caps on the two universal joints were more heavily painted and

the name was not as clear. Author's photo.

Blood Brothers Machine Company World War

Two Products: The company

produced universal joints and propeller shafts for several different

military vehicles during the war. Table 1 shows information

obtained from several pre-World War Two newspaper articles on War

Department (U.S. Army) contracts the company was awarded. After

the attack on Pearl Harbor, military contracts were normal business and

no longer mentioned in the newspapers. All of the information I

have been able to acquire on the company shows that it produced

universal joints and propeller shafts for various military vehicles.

However, there was one news article dated

October 30, 1942, in the Detroit Free Press that named the Blood

Brothers as furnishing components to two Michigan ship building

companies. Great Lakes Engineering Works in River Rouge, MI, and

the Lyons Construction Company of Whitehall, MI were reported as being

two shipyards that were producing ships for the war effort. Great

Lakes Engineering Works produced at least 20 ore carriers during the war

along with other types of cargo ships. The cargo ships had a need

for some applications for universal joints manufactured by the Blood

Brothers Machine Company of Allegan, MI. Blood Brothers may have

also been a supplier for other undocumented wartime applications.

Also, one historical document notes that 900

workers were employed at the Blood Brothers' plant making Jeep

components. The 1945 edition of the Ordnance Supply Catalog for

the Ford GPW and Willys-Overland MB does not show the Blood Brothers as

being a supplier. However, it may have been making the parts under

subcontract to another company or was a supplier early in the war.

Suppliers may have changed for the Jeep as the war progressed.

What this does tell me is that there is more to the story that I have

yet to uncover. However, I have found and presented a sufficient

amount of information to show that the Blood Brothers Machine Company of

Allegan, MI was, like many other small companies in the United States,

instrumental in helping to win World War Two.

|

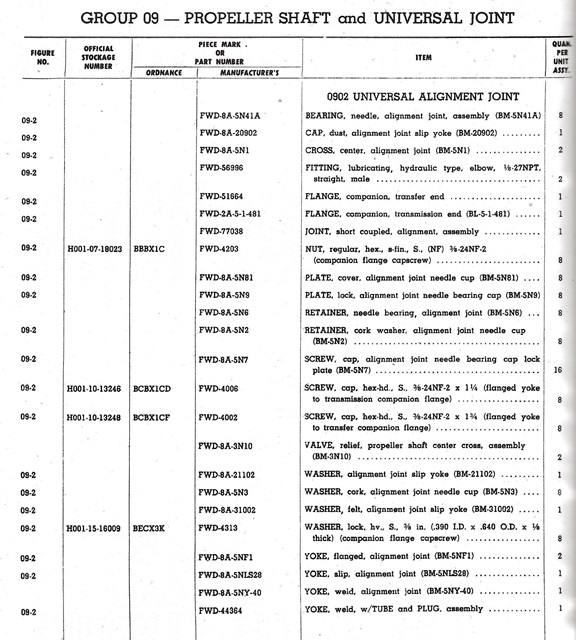

Table 1 - Blood Brothers Machine Company

Government Contracts |

|

Product - Customer |

Contract Amount |

Date |

| Universal Joints - War

Department |

$1,410.00 |

December 1940 |

| Flexible Joints - War

Department |

$2,261.60 |

August 1941 |

| Flexible Joints - War

Department |

$4,528.00 |

September 1941 |

|

Total |

$8,199.60 |

|

Table 2 shows that the Blood Brothers Machine

Company furnished universal joints and propeller shafts for a variety of

trucks and for the M4/M4A1 Sherman tanks. The M4/M4A1 Sherman

tanks were powered by a Continental radial aircraft engine. There

were several types of Sherman tanks produced during World War Two with

different engines. However, the M4/M4A1 series was the type

utilized by the United States Army for the entire conflict. They

were used in North Africa and Italy, landed with American forces at

Normandy in June 1944, and served until V-E Day. One of the

attributes of the Sherman tank was its reliable drivetrain, of which the

Blood Brothers universal joints and propeller shafts were an important

component. The Blood Brothers Machine Company was instrumental in

helping to win World War Two.

|

Table 2 - Known Blood Brothers Machine Company World War Two

Military Product

Applications |

|

Product Type |

Vehicle Manufacturer |

Vehicle Application |

Number of Vehicles Built |

| Various

Propeller Shafts and Universal Joints |

Ward-LaFrance |

M1

and M1A1 Wreckers 6x6

|

4,925 |

| Various

Propeller Shafts and Universal Joints |

Kenworth |

M1

and M1A1 Wreckers 6x6

|

840 |

| Universal

Joints |

Four

Wheel Drive Auto Company |

Truck, 4-ton,

4x4, Cargo HAR-1 |

7,000 |

| Universal

Joints |

Four

Wheel Drive Auto Company |

Truck, 5-6-ton,

4x4, Prime Mover and Cargo SU-COE |

4,481 |

| Various

Components - Front Winch |

Brockway |

6-Ton, 6x6

Chassis for Bridge Erector |

1,166 |

| Various

Components - Front Winch |

FWD |

6-Ton, 6x6

Chassis for Bridge Erector |

168 |

| Various

Components - Front Winch |

Ward LaFrance |

6-Ton, 6x6

Chassis for Bridge Erector |

589 |

| Various

Components - Front Winch |

White |

6-Ton, 6x6

Chassis for Bridge Erector |

1,152 |

| Propeller

Shaft Universal Joints |

Corbitt |

6-Ton, 6x6

Prime Mover |

3,211 |

| Propeller

Shaft Universal Joints |

White |

6-Ton, 6x6

Prime Mover |

4,946 |

| Propeller

Shaft Universal Joints |

White |

6-Ton, 6x6

Van Chassis |

1,870 |

| Propeller

Shaft Universal Joints |

White |

6-Ton, 6x6

2000 Gallon Tank Truck |

25 |

| Total

Trucks |

|

|

30,373 |

| |

|

|

|

| Propeller

Shaft Universal Joints |

Alco |

M4(75)VVSS

Sherman Tank |

2,150 |

| Propeller

Shaft Universal Joints |

Baldwin |

M4(75)VVSS

Sherman Tank |

1,233 |

| Propeller

Shaft Universal Joints |

Chrysler

|

M4(75)VVSS

Sherman Tank |

1,676 |

| Propeller

Shaft Universal Joints |

Chrysler

|

M4(105)VVSS

Sherman Tank |

1,641 |

| Propeller

Shaft Universal Joints |

Pressed Steel |

M4(75)VVSS

Sherman Tank |

1,000 |

| Propeller

Shaft Universal Joints |

Pullman

Standard |

M4(75)VVSS

Sherman Tank |

689 |

| Total M4

Tanks |

|

|

8,389 |

| |

|

|

|

| Propeller

Shaft Universal Joints |

Lima

Locomotive Works |

M4A1(75)VVSS

Sherman Tank |

1,655 |

| Propeller

Shaft Universal Joints |

Pacific Car

and Foundry |

M4A1(75)VVSS

Sherman Tank |

926 |

| Propeller

Shaft Universal Joints |

Pressed Steel |

M4A1(75)VVSS

Sherman Tank |

3,700 |

| Total M4A1

Tanks |

|

|

6,281 |

| |

|

|

|

| Propeller

Shaft Universal Joints |

Alco |

M7 105mm Gun

Motor Carriage |

3,314 |

| Propeller

Shaft Universal Joints |

Federal

Machine and Welder Company |

M7 105mm Gun

Motor Carriage |

176 |

| Total M7

Gun Motor Carriages |

|

|

3,490 |

| |

|

|

|

| Propeller

Shaft and Universal Joint |

Clark

Equipment Company |

Clark

Planeloader Forklift Truck |

? |

Trucks:

Four Wheel Drive Auto Company HAR-1:

Blood Brothers' universal joints were used

in several locations on the HAR-1. This is the universal joint at

the parking brake. The transfer case is behind the parking brake.

Author's photo.

This image shows the bottom side of the

transfer case with the output shafts. Blood Brothers universal

joints are used on each output shaft. Author's photo.

A Blood Brothers universal joint is at the

front differential. Author's photo.

Author's photo.

The universal joint at the rear axle was also made by the Blood Brothers

Machine Company. The Four Wheel Drive Auto Company produced 7,000

HAR-1 trucks with Blood Brothers universal joints installed. Author's photo.

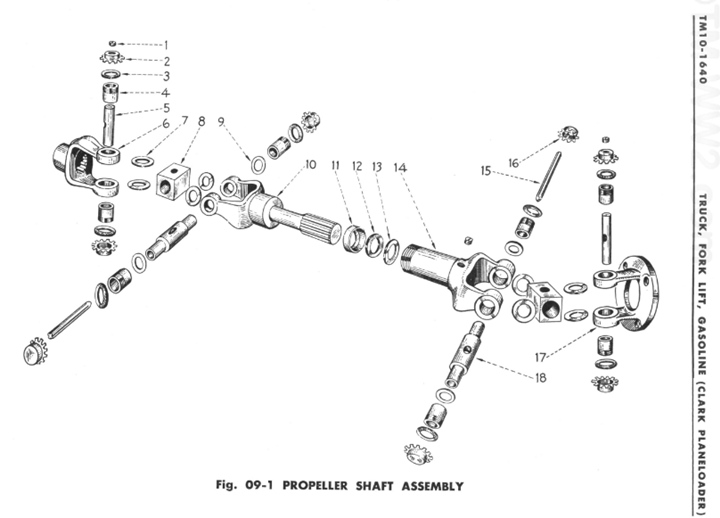

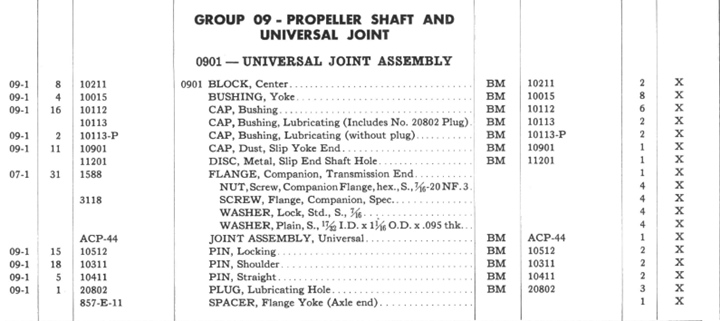

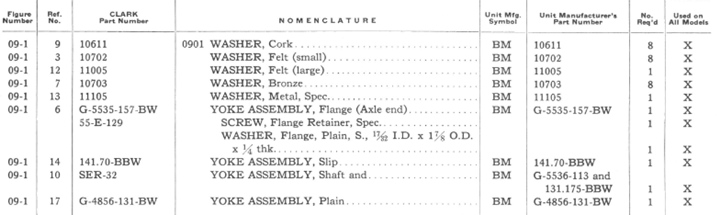

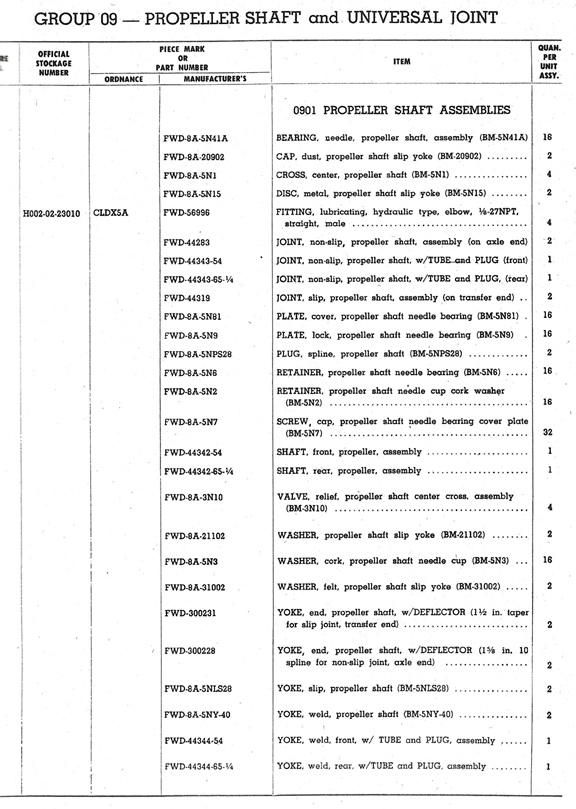

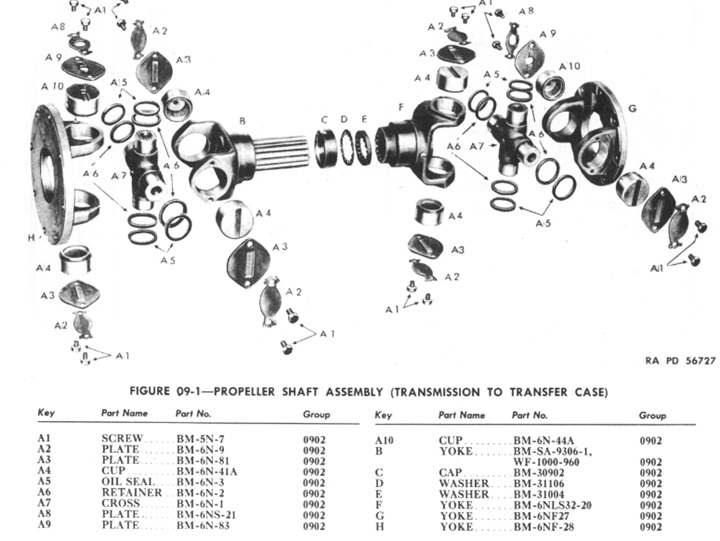

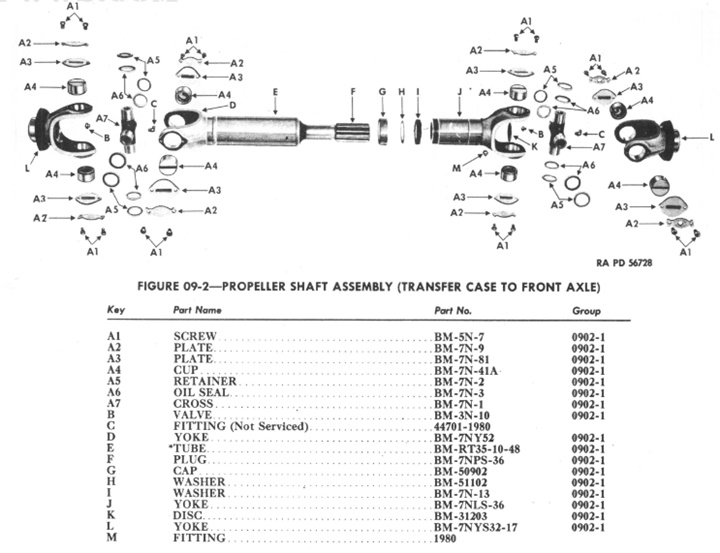

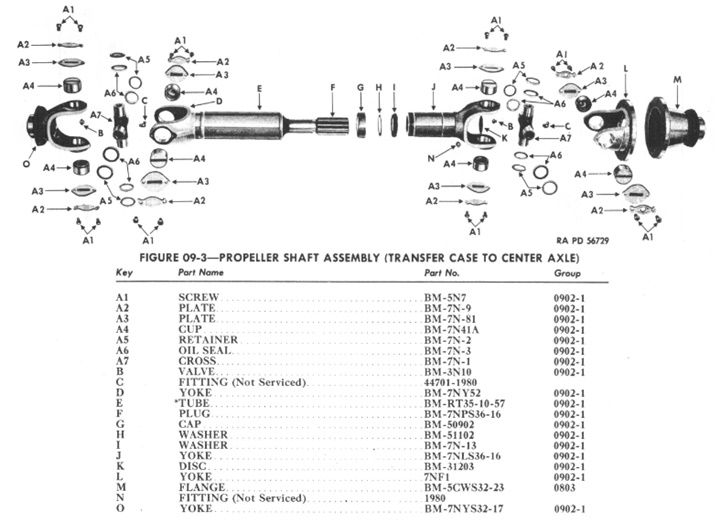

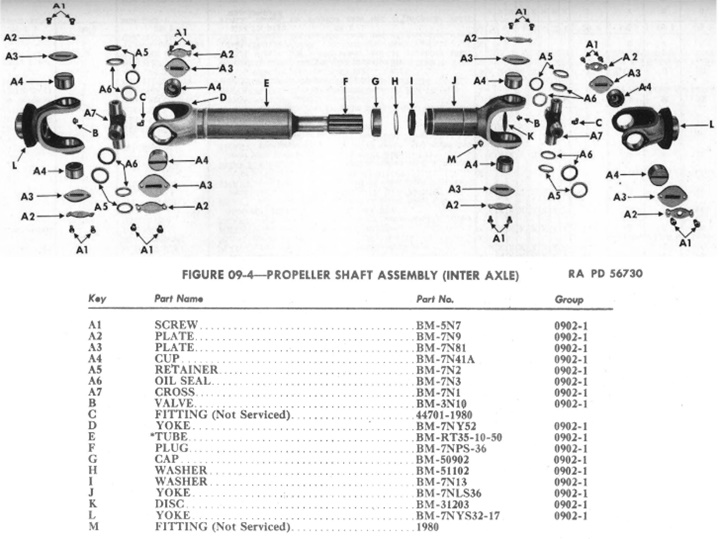

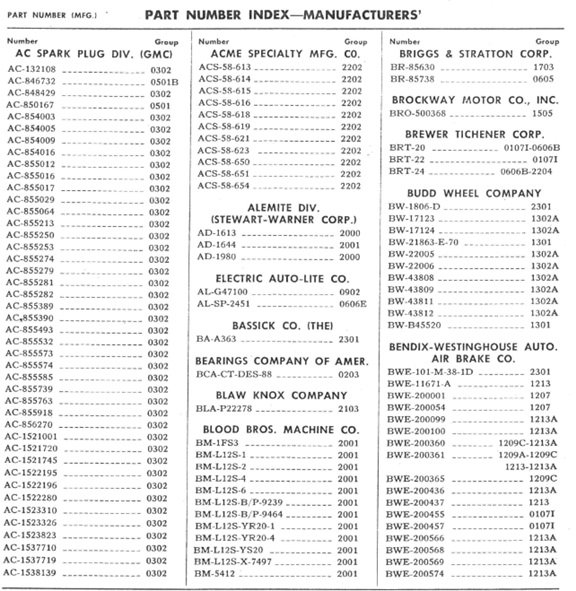

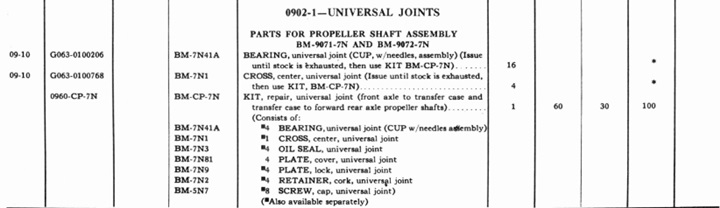

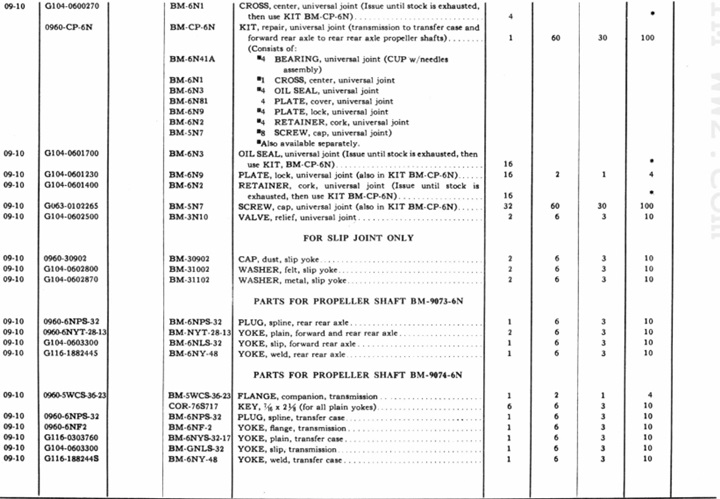

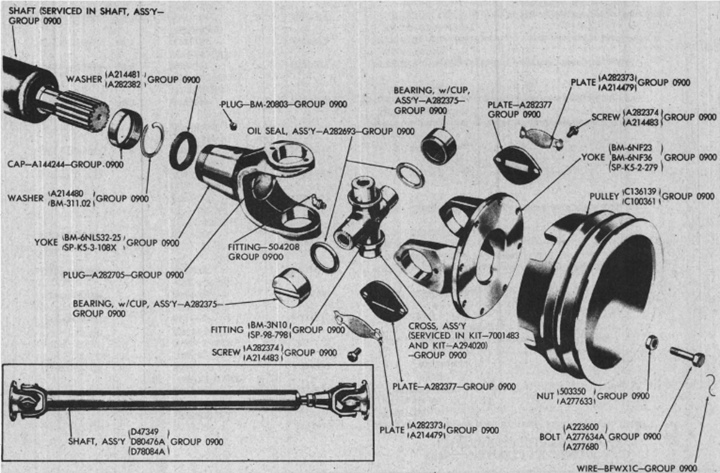

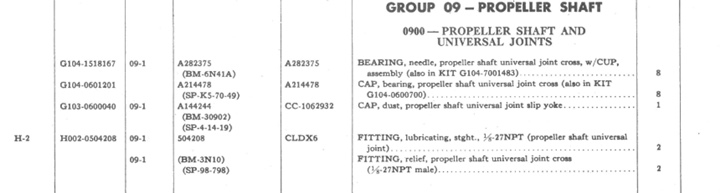

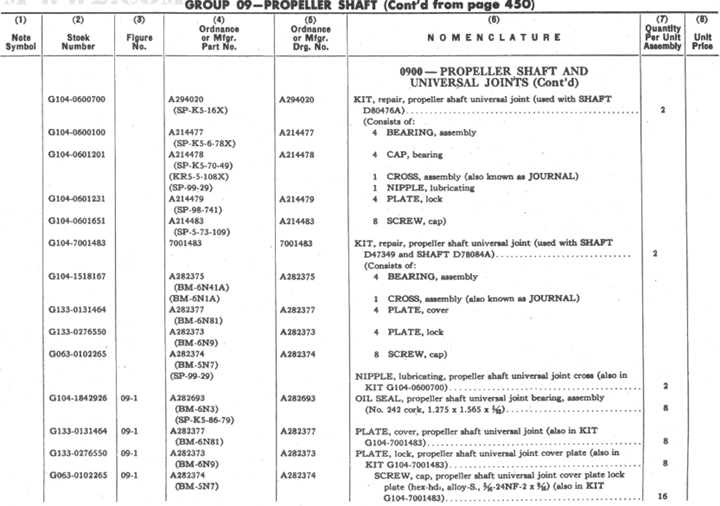

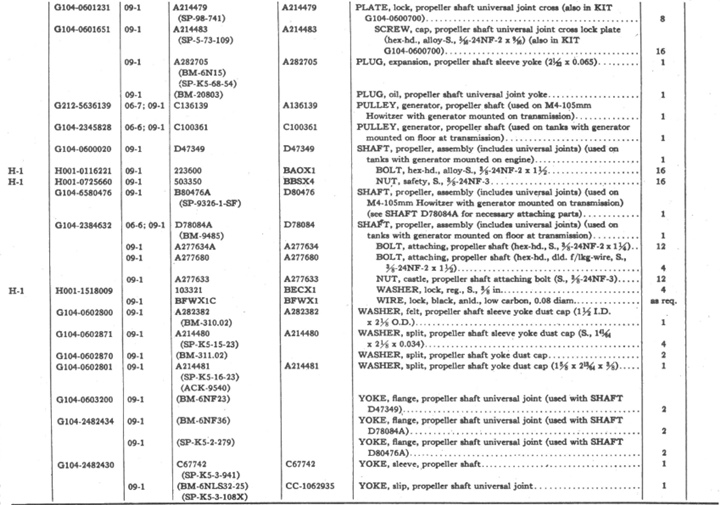

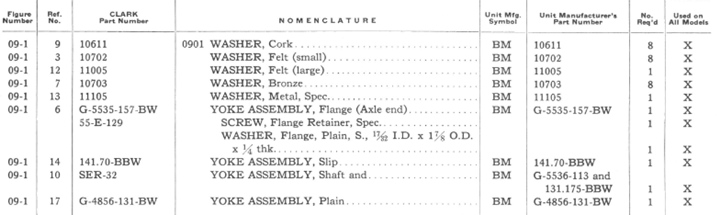

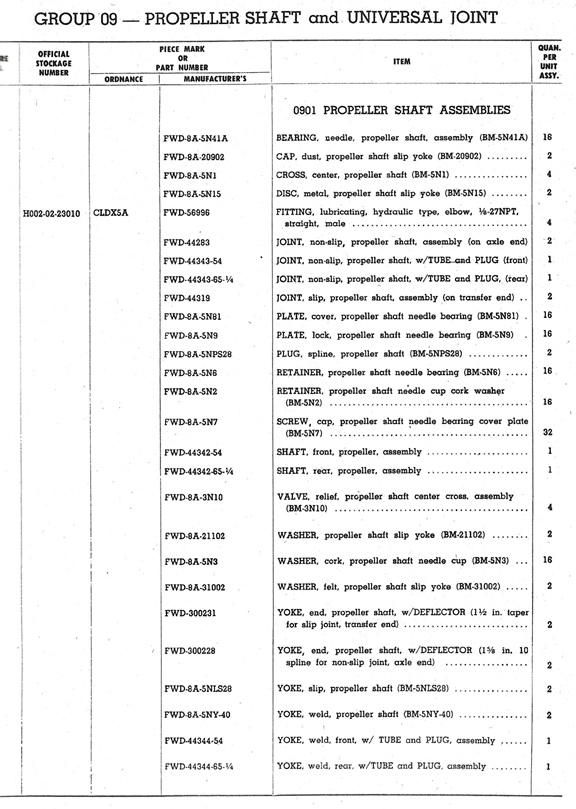

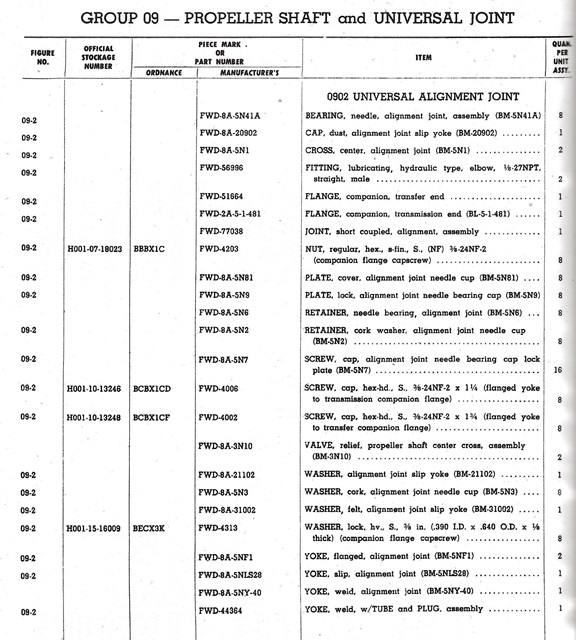

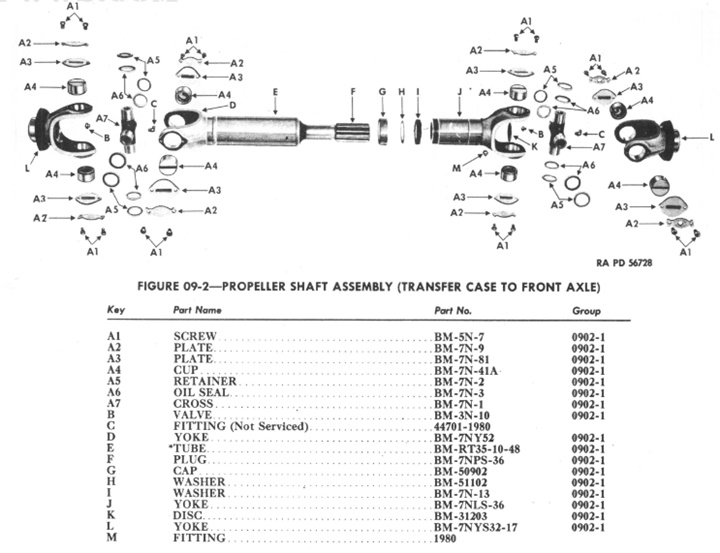

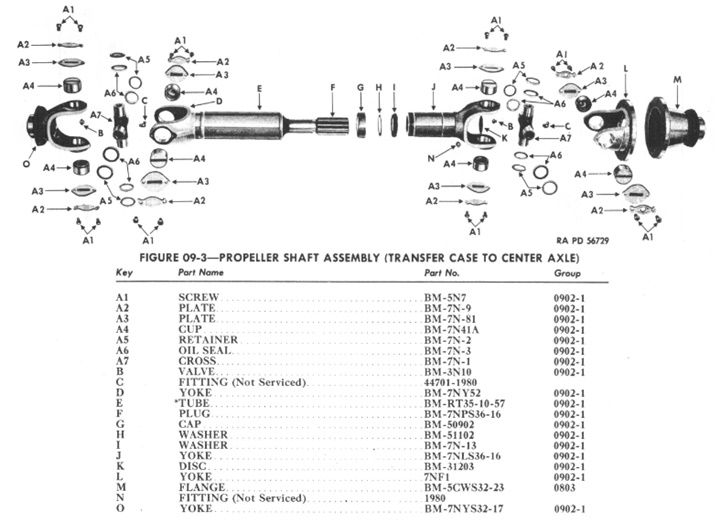

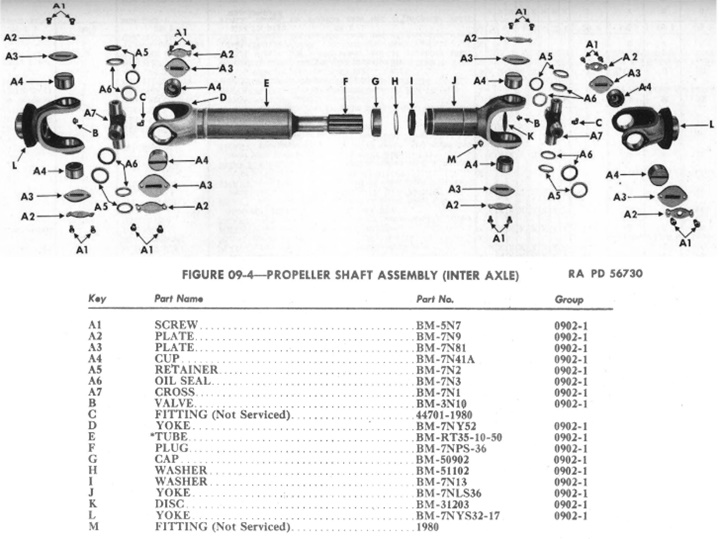

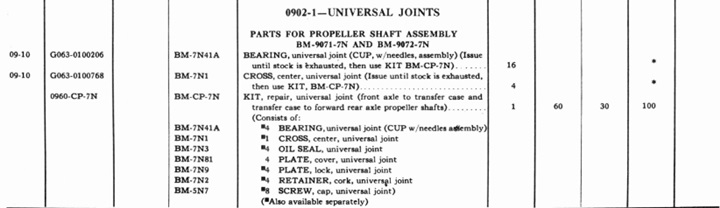

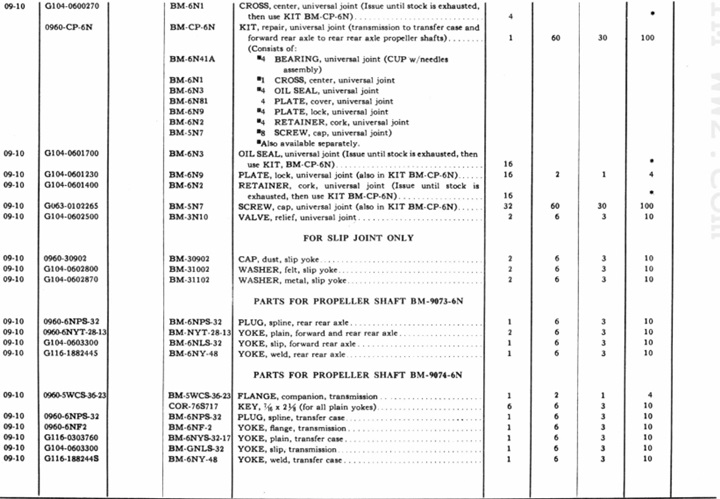

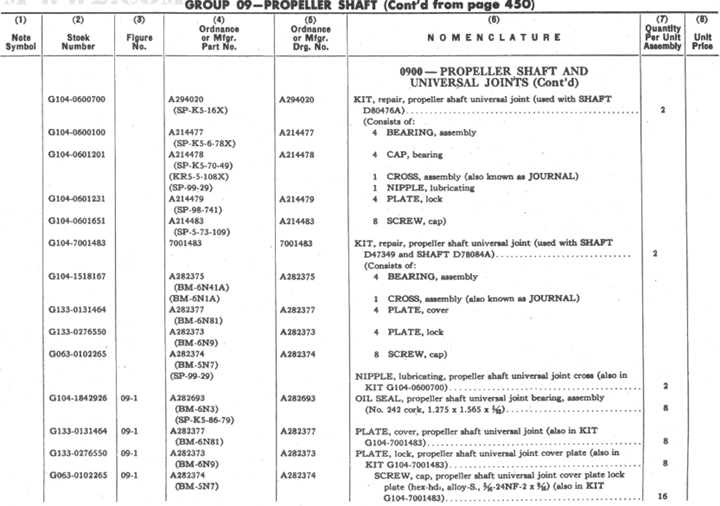

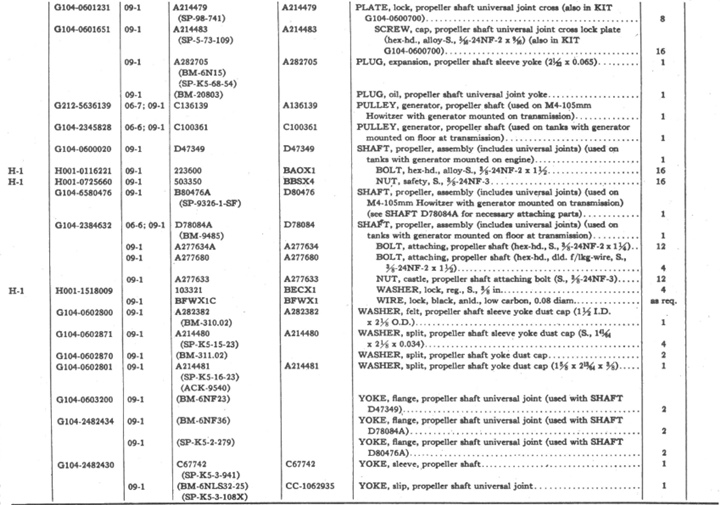

This and the following image are from the

Ordnance Supply Catalog for the HAR-1. BM designates a Blood

Brothers Machine Company component.

Four Wheel Drive Auto Company SU-COE:

Image added 10-15-2023.

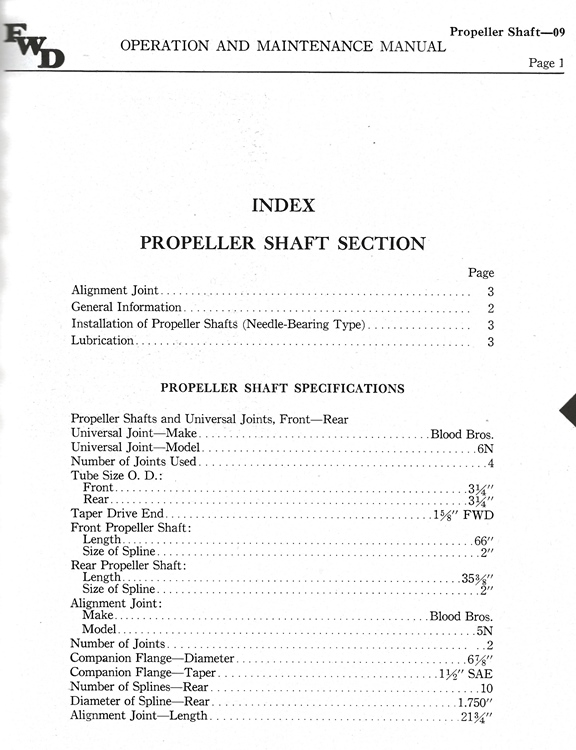

This page from the FWD SU-COE Operation and

Maintenance Manual shows that the vehicle used both the Blood Brothers

Model 6N and 5N universal joints. Image added 10-15-2023.

M1

and M1A1 Wreckers 6x6:

Ward LaFrance and Kenworth

built 5,765 M1 and M1A1 wreckers equipped with Blood Brothers propeller

shafts and universal joints.

This is a Ward LaFrance Series 2 M1 heavy

wrecker. Author's photo.

This is an M1A1 Ward LaFrance heavy wrecker.

Author's photo.

Below are the pages from the Ordnance Supply

Catalog, showing the Blood Brothers Machine Company components (BM) used

on the M1/M1A1 series wreckers.

6-Ton 6x6

Chassis for Bridge Erector: Brockway, Four Wheel

Drive Auto Company, Ward LaFrance, and White built a total of 3,075 of

these types of vehicles. Blood Brothers supplied several

components for the front winch on the vehicle.

This image shows the front winch which

consisted of some Blood Brothers parts. Photo courtesy of

Pierre-Olivier Baun.

This is a listing of the Blood Brothers

parts used in the front winch.

6-Ton, 6x6

Prime Mover: Corbitt and White built a combined

total of 8,157 of this type of truck. White also produced 1,870

vans on this chassis and 25 2,000 gallon tankers. The Blood

Brothers furnished components for the propeller shafts and universal

joints.

This is a White-built six-ton 6x6 prime

mover. Author's photo.

This is the Corbitt version of the vehicle.

Author's photo.

M4(75)VVSS Sherman Tank: The

Sherman tank is the iconic American tank of World War Two. It was

known for the durability and reliability of its drivetrain. Blood

Brothers Machine Company supplied components for the propeller shafts

and universal joints for the M4/M4A1 series of Sherman tanks that

were instrumental in keeping the vehicles running.

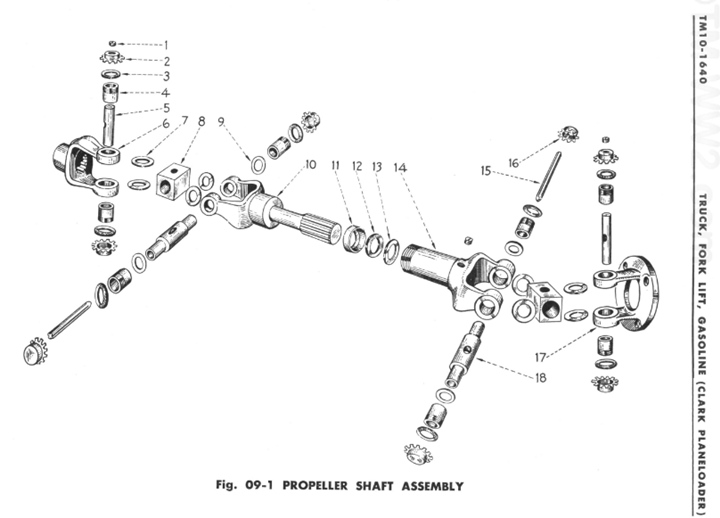

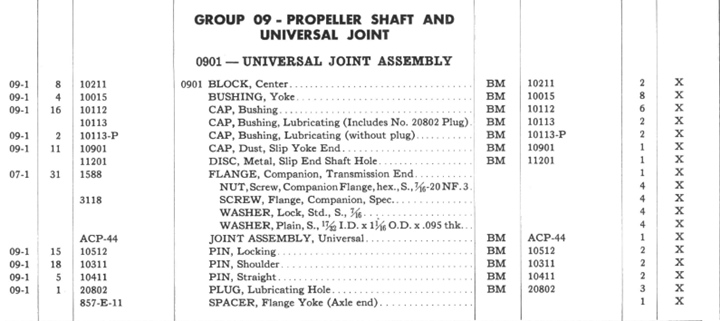

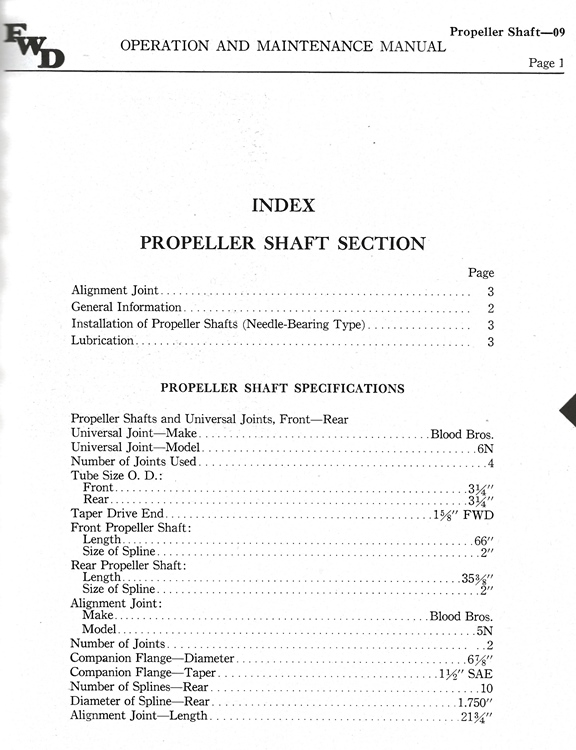

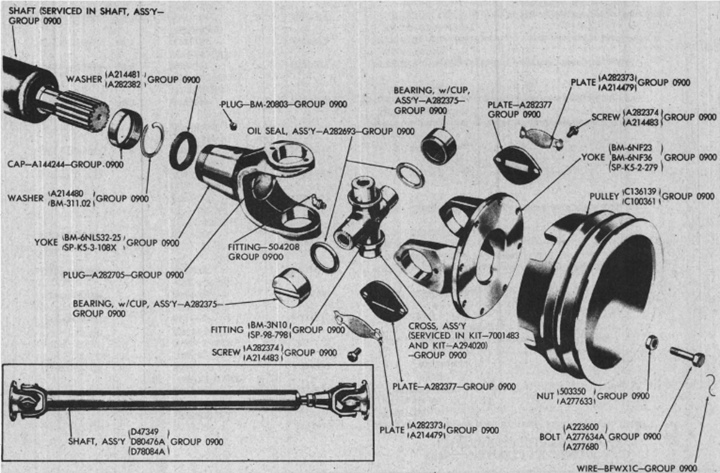

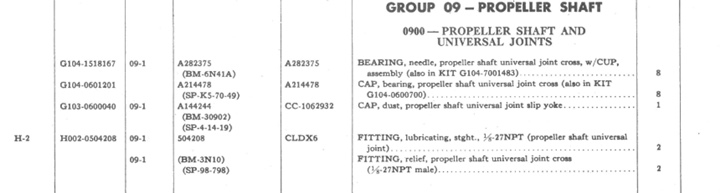

This document and the one below show the

Blood Brothers (BM) components used on the M4/M4A1 Sherman tank and the

105mm Gun Motor Carriages. Note that there were several companies

that supplied parts for these components.

Six different companies built the M4 Sherman

tank. Photos representing four of the six manufacturers are shown

below.

-fortbenning-2018-107w-1.jpg)

This is one of 2,150 Alco-built M4 Sherman tanks

and was built in April 1943. Author's photo.

-crestviewfl-sn1765-2022-107w-1.jpg)

This Alco-built M4 was also built in April

1943, and is the oldest surviving Alco M4. Author's photo.

This

M4E9(75) was built by Pressed Steel and is on display at the USS Alabama

in Mobile, AL. Pressed Steel built 1,000 M4 Sherman tanks. Author's photo.

Pullman Standard built 689 M4s like this one. Author's photo.

Chrysler built 1,641 M4s with 105mm

howitzers like this one. It also built another 1,000 with a 75mm

main gun. Author's photo.

M4A1(75)VVSS Sherman Tank: The

M4A1 was different from the M4 in that it had a cast, rather than a

welded hull. However, the drivetrains were the same.

Of the 1,655 M4A1 Sherman tanks that Lima

built, only nine are known to still exist. This is one of three

that are in the United States. It is believed to be Serial Number 7321,

which was built in February 1943. It was converted to a

flamethrower tank and is on display at the Fort Leonard, MO museum

complex. Author's photo.

Pacific Car and Foundry built 926

M4A1(75)

VVSS Sherman tanks like this one on display at the Fort Leonard Wood, MO

Museum outside tank park. It is the only one in the United States,

and one of six remaining in the world. Production of the M4A1

started in May 1942 and finished in November 1943. Author's photo

added 6-11-2018.

This Pressed Steel-built small hatch

M4A1(75) is serial number 192, built in July 1942. It

is USA number 3014948. It is the oldest Pressed Steel

M4A1(75) known to exist and is owned by the Virginia Military Museum of

Military Vehicles. Note that this tank has the direct vision ports

for the driver and assistant driver. Author's photo.

M7 105mm Gun Motor Carriage:

The M7 used the same chassis as the

M4 and M4A1 Sherman tanks. The Blood Brothers Machine Company

provided components for the propeller shafts and universal joints for

this type of vehicle.

Alco built 3,314 M7s like this one built in November 1942. The Federal

Machine and Welder Company built another 176.

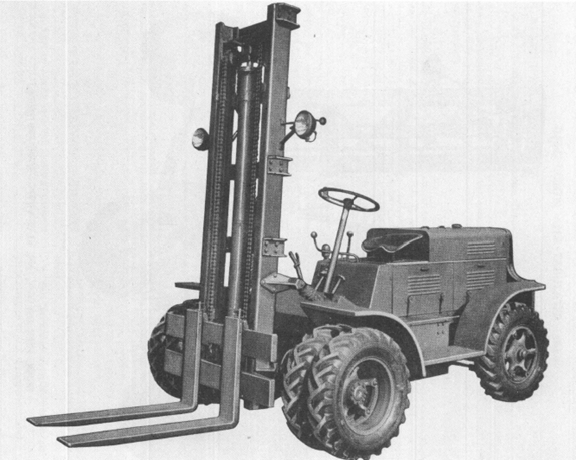

Clark Equipment Company Planeloader

Forklift Truck: An undetermined number of Planeloaders were

built by Clark in nearby Battle Creek, MI. The Blood Brothers

Machine Company supplied universal joints and propeller shaft

components.

|

-fortbenning-2018-107w-1.jpg)

-crestviewfl-sn1765-2022-107w-1.jpg)