|

Miller

Printing Machinery Company in World War Two

Pittsburgh, PA

1903-1988

1945-1976 Purchased by Commercial Credit of Baltimore, MD in 12-1945

1976-1980 Owned by Western Gear Corporation

1980-1988 Owned by Fritz Werner Industrie-Ausruestungen GmbH

1981 Renamed Miller Printing Equipment Corporation

This page updated 4-4-2023.

Ever since 2013, when I started

investigating the different products manufactured by American Industry

to help win World War Two, I was curious as to which company produced

the 75mm recoilless rifle. This weapon was introduced late in

World War Two and saw most of its use in the Okinawa campaign. The

historical record of Oldsmobile Division of General Motors mentions

possible production of the 75mm recoilless rifle, but that production

never happened. While visiting military museums over the years, I

found several recoilless rifles on display, but the manufacturer of the

weapon was never identified.

In June 2022, I made an online purchase of a

book about companies that won the "E" award from the Pittsburgh, PA

area, "To the Unsung Heroes of the Production Front" by Wallace Priest.

Browsing through the book, I found this on page 68: "Miller

Printing Machinery Company has already been mentioned for its

development and production of the 75mm recoil-less rifle..." This

is the name of the company for which I had been looking for nine years.

With the company name now known, further research proceeded rapidly,

resulting in this webpage. Interestingly enough, the purchase of

the book was not planned. I was actually searching for a book on

another topic when I found "To the Unsung Heroes of the Production

Front."

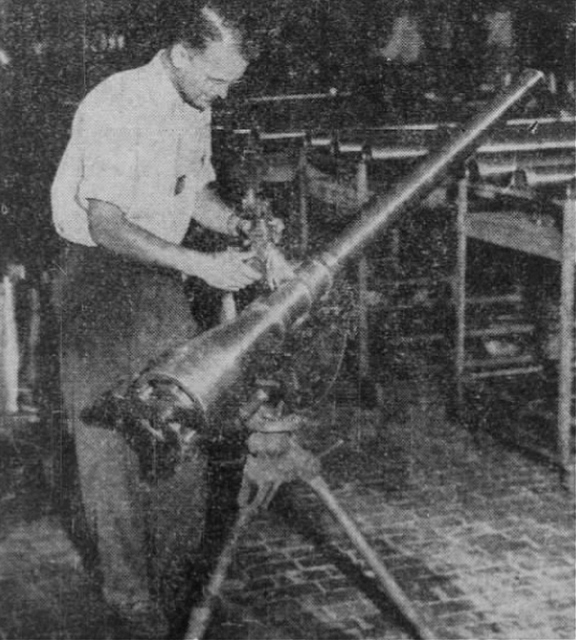

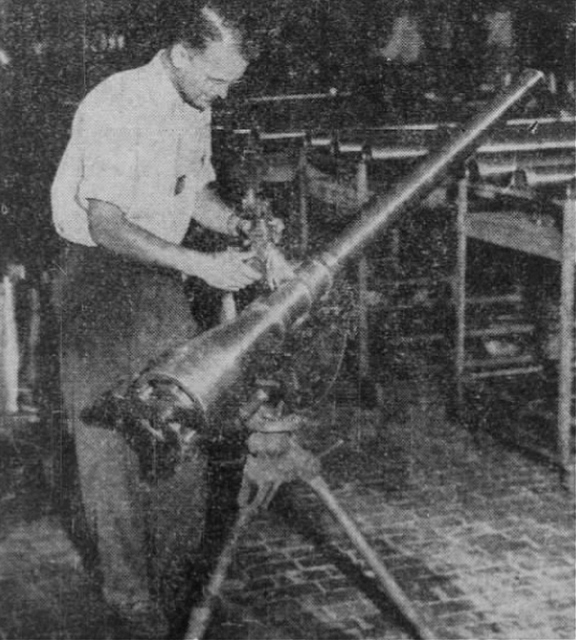

On July 13, 1945, the photo above appeared in

the Pittsburgh, PA Post-Gazette along with a related article on Miller

Printing Machine Company's production of what was described as a "kickless

gun." For years I had been searching for the manufacturer of

the recoilless rifle, and within a few minutes of searching through

online newspaper files, I found a photo of it being produced at the

factory. Recoilless rifle barrels on an assembly line can be seen

in the background of the photo.

The article also gave the address of

the company as 1117 Reedsdale Street, in the North Shore section of Pittsburgh.

Further research of this location indicates it was very near the present

day Three

Rivers Stadium in downtown Pittsburgh. Previous to the

redevelopment and repurposing of the area along Reedsdale Street, there

were several industrial companies including Carnegie Steel Company.

Currently, all of the old factories have been replaced by ball stadiums,

casinos, and museums.

The Miller Printing Machinery Company won

the Army-Navy "E" Award three times in World War Two.

Miller Printing Machinery Company World War

Two Products: In another reference to the Miller Printing

Machinery Company in the "To the Unsung Heroes of the Production Front,"

it notes the company was an important supplier of M22 and M23 gun

mounts. These items were new to me, so I had to do some research

to determine what they were. My research found that the M22 gun

mount was used in the M3 Stuart light tank and the M23 was utilized in

the M3A1 and M5 Stuart tanks. Table 1 shows that the company also

made parts for the M44 mount, which was used in the M5A1. While

the proceeding gun mount listings in Table 1 do not indicate the type of

mounts being made, it can be assumed that the company also produced the

M44 mount as a complete unit for installation in the M5A1 light tank.

Miller Printing Machinery Company was cited in

"To the Unsung Heroes of the Production Front," "...for its early and

consistently outstanding production of gun mounts..." No doubt

this led to the three Army-Navy "E" Awards the company received during

the war.

The company had $16,784,000 in major war

contracts during World War Two. Of this amount, $14,403,000 was

for gun mounts and related components. This was 86% of the total

value of contracts. Production of the gun mounts began in

September 1940.

$2,403,000 worth of contracts were for the

development and production of the 1,238 75mm recoilless rifles built by

the company. It was the sole supplier of the weapon in World War

Two.

During World War Two the company employed

approximately 1,000 employees to make the gun mounts and recoilless

rifles. This was over three times the number of employees the

company had in 1939 before the war started.

Table 1 - Miller Printing

Machinery Company's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Mounts Gun

- Army |

$2,338,000 |

9-1940 |

2-1942 |

| Mounts Gun

- Army |

$508,000 |

10-1940 |

7-1941 |

| Ordnance Material

- Army |

$148,000 |

6-1941 |

3-1942 |

| Mounts Gun

- Army |

$496,000 |

10-1941 |

6-1942 |

| Mounts Gun

- Army |

$177,000 |

11-1941 |

8-1942 |

| Mounts Gun

- Army |

$945,000 |

1-1942 |

8-1942 |

| Gun Parts - Army |

$75,000 |

3-1942 |

5-1942 |

| Mechanism Recoil

- Army |

$125,000 |

8-1942 |

11-1942 |

| Mounts Gun

- Army |

$185,000 |

11-1942 |

11-1942 |

| Gun Director

Parts - Army |

$1,177,000 |

2-1943 |

4-1944 |

| Gun Mount Kits -

Army |

$1,000,000 |

5-1943 |

10-1943 |

| Gun Sight

Assemblies - Army |

$328,000 |

7-1943 |

1-1945 |

| Machine Gun Mount

Kits - Army |

6,398,000 |

12-1943 |

1-1944 |

| Gun Mount Parts -

Army |

$68,000 |

7-1944 |

11-1944 |

| Gun Mount Parts

M44 - Army |

$349,000 |

11-1944 |

2-1945 |

|

Recoilless Rifles 75mm - Army |

$115,000 |

11-1944 |

2-1945 |

| Recoilless Rifles

- Army |

$1,576,000 |

11-1944 |

8-1945 |

| Light Tanks -

Army |

$69,000 |

2-1945 |

6-1945 |

| Gun Elevating

Mechs - Army |

$86,000 |

4-1945 |

8-1945 |

| Rifle Parts 75mm

- Army |

$267,000 |

5-1945 |

8-1945 |

| Rifles 75mm T25 -

Army |

$445,000 |

5-1945 |

8-1945 |

| Total |

$16,784,000 |

|

|

Table 2 - Miller Printing Machinery Company's 75mm

Recoilless Rifle Monthly Production

This table added 9-8-2022. |

|

1945 |

Number Produced |

|

February |

37 |

|

March |

73 |

|

Arpil |

200 |

|

May |

300 |

|

June |

306 |

|

July |

100 |

|

August |

222 |

|

Total |

1,238 |

Table

3 -

Miller Printing Machinery Company's

Machine Gun Mounts

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. This table added 4-4-2023.

|

|

Type |

Contract Number |

1943 |

1944 |

1945 |

Total |

|

Ring Mount M49 |

W-761-ORD-3105 |

5,981 |

6,019 |

0 |

12,000 |

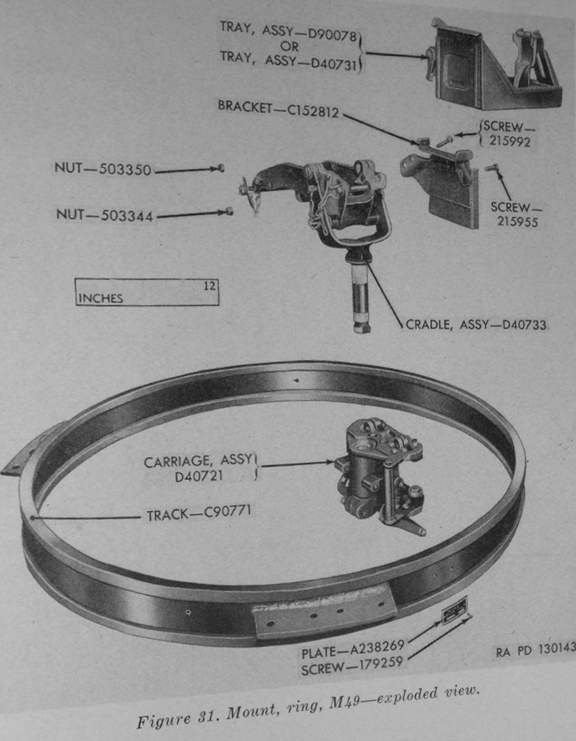

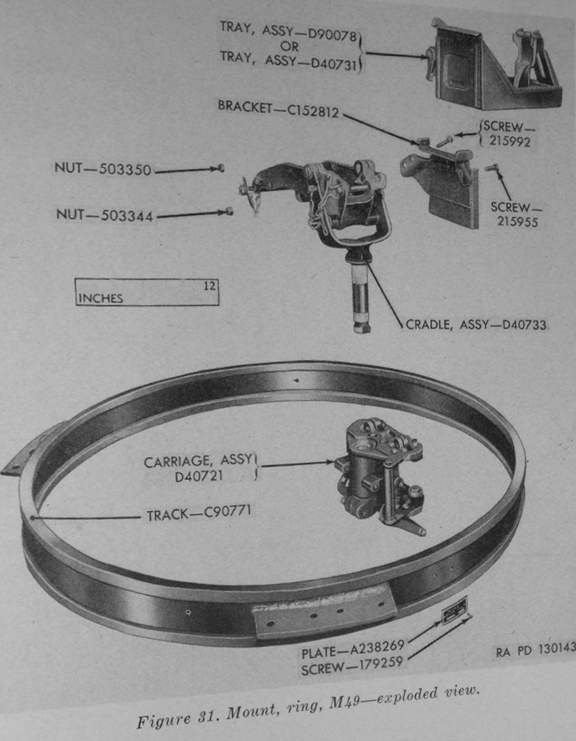

M49 Ring Mount:

Contract W-761-ORD-3105 shown in Table 3 corresponds to the

$1,000,000 contract issued in May 1943 and completed in October

1943. Each M49 ring mount cost $83.33.

This image shows all of the

components for the M49 ring mount. Image added 4-4-2023.

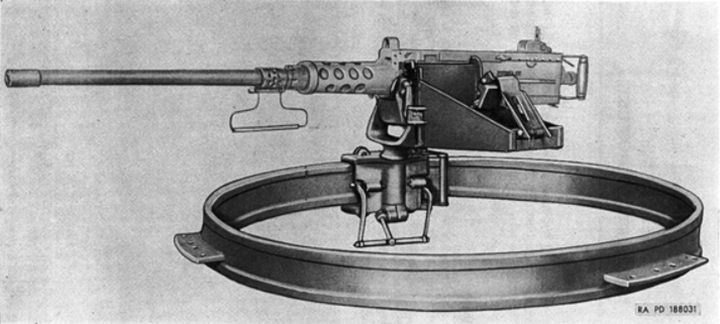

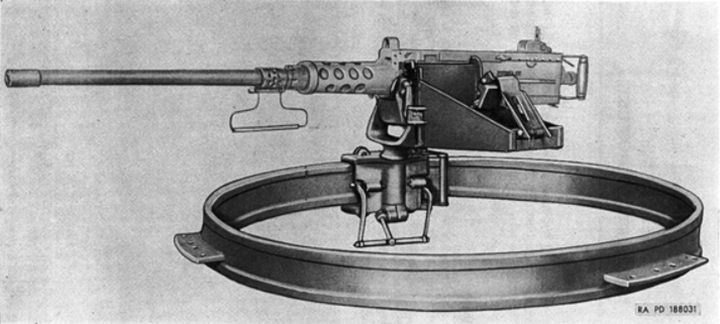

The M49 ring mount was utilized to

add .50 caliber machine gun anti-aircraft protection to

different types of vehicles. The M49 ring mount became

part of a larger unit when assembled with a mount that attached

to the vehicle. Image added 4-4-2023.

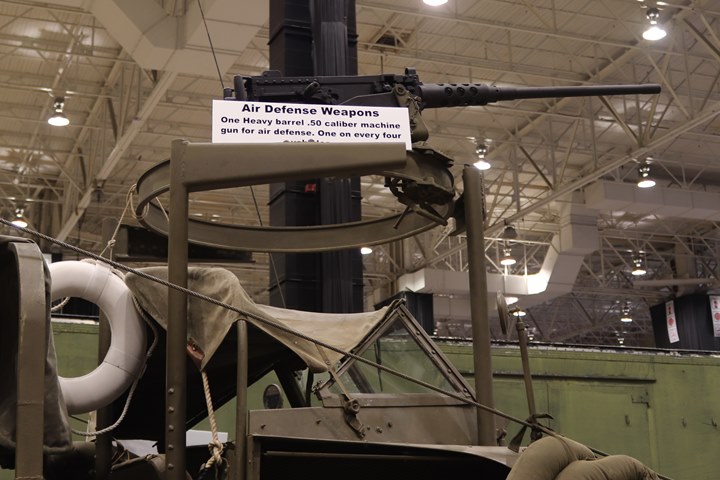

An M49 ring mount was added to this 1943 GMC CCKW-352 2-1/2-ton

6x6 truck. Author's photo added 4-4-2023.

Here, an M49 ring mount was added to a GMC CCKW-353

2-1/2-ton 6x6 truck. In this case, two .30 caliber machine

guns have been mounted on the M49 ring mount. Author's

photo added 4-4-2023.

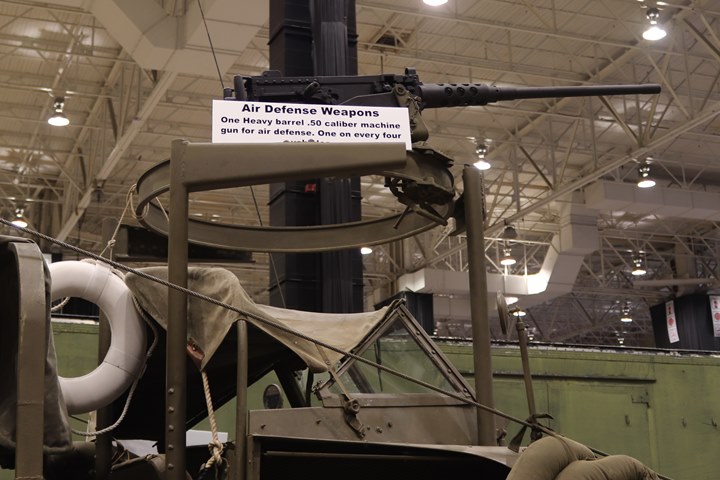

M49 ring mounts were also added to

many GMC DUKW amphibious trucks. Author's photo added

4-4-2023.

The information placard notes that

25% of the DUKWs were equipped with M49 ring mounts for

anti-aircraft defense. Author's photo added 4-4-2023.

M2A1, M3A1, M5A1, and M9A1 half-tracks were

equipped with the M49 ring mount. This White M3A1 is on display at the Indiana

Military Museum in Vincennes, IN. Author's photo added 4-4-2023.

The M20 command car came equipped with a .50

caliber machine gun for defense mounted on an M49 ring mount.

Author's photo added 4-4-2023.

M44 Mount:

Shown here is an M44 mount in an M5A1 Stuart

light tank. Miller Printing Machinery Company was instrumental in

supplying these for the 6,810 M5A1s that were built. Author's

photo.

This M5A1 was on display at the 2014 St.

Louis Airshow, which allowed for photos of the M44 gun mount inside the

turret. Author's photo.

This M3A1 is on display at the Indiana

Military Museum in Vincennes, IN. The M3A1 light tanks were

equipped with M23 gun mounts built by Miller Printing Machinery Company.

Author's photo.

75mm Recoilless Rifle:

There are several 75mm recoilless rifles on

display at military museums. This one is located at the National

Museum of the United States Marine Corps. The 75mm recoilless

rifle was designed to be mounted on a .30 machine gun tripod.

Author's photo.

This 75mm recoilless rifle is on display at

the Roberts Armory in Rochelle, IL. The location of it in the

museum allows for photographs from several different angles.

Author's photo.

Author's photo.

This image shows the holes in the shell,

which were designed to allow the gases to escape from the rear of the

weapon, resulting in no recoil. However, the escaping gases created

a hazard for any troops behind the weapon. The resulting smoke cloud

also gave away the weapon's position to enemy forces. Author's

photo.

Author's photo.

|