|

W.L. Maxson

Corporation in World War Two

New York, NY

1935-1964

1964-1969 as Maxson

Electronics

1969-1975 as Riker-Maxson Corporation

1975-~1987 - In 1975 Riker-Maxson changed its name to Unimax Switch

Corporation

This page updated 10-12-2022.

This is a Multiple Caliber .50 Machine

Gun Mount M45. It is more commonly known as the Maxson Quadmount,

named after W.L. Maxson who invented the weapon. This is one of

the few weapons of World War Two that is known by the inventor's name.

While the Maxson Quadmount is well known among

military historians and collectors, little is known of the company that

bears M.L. Maxson's name. There is no record of the company's

products before or after World War Two, with the exception of a proposed

idea M.L. Maxson was working on at the time of his death in 1947. He had

developed a concept with Pan-American Airlines that was similar to what later became TV dinners. At that time, airlines had no way of

preparing hot meals for its customers. W.L. Maxson invented an

oven, similar to a convection oven, to cook pre-packaged meals.

After the death of his father, W.L. Maxson, Jr. became president of the

company.

More is known about the man himself than his

company or what it did during World War Two. William Leslie Maxson was born on May 10, 1898, in Necedah, WI. He graduated from

the U.S. Naval Academy in 1921 and served with the Navy until 1935, when

he started his company. He died from post-surgical complications on July 15, 1947,

at age 49. The M45 was the second multiple gun mount that W.L.

Maxson invented. The first was the M33 twin .50 caliber mount,

which was standardized by Army Ordnance on 2-26-1942 as the Twin Caliber

.50 Multiple Machine Gun Mount. It was primarily mounted on the M13

halftrack. While W.L. Maxson invented and built prototypes of his

gun turrets, his company did not receive the production contracts.

These were won by Kimberly-Clark and Landers, Frary & Clark as shown in

the table 1 below. Maxson did produce the variable speed drives for

the turrets.

The W.L. Maxson Corporation continued

operations after World War Two outside of New York City, NY. One

factory was located at Great River, NY and a second plant was opened in

1951 in Old Forge, PA. The company re-focused on the manufacture

of electronic devices and was renamed Maxson Electronics. In 1963

the New York City operations were moved to the Great River, NY facility

which then became the company's headquarters. Of significance was a $23.5 million contract to build the Bullpup

air-to-ground missile for the U.S. Air Force in Old Forge, PA.

This was a Martin-Marietta-designed weapon that Maxson Electronics

produced after Martin-Marietta stopped production. Of the 4,600

Bullpup missiles built, Maxson Electronics is credited with building the

majority of the missiles. This may well have been Maxson

Electronics signature product after World War Two. It was also its

swan song product, because after production ended in 1969, the

Old Forge, PA plant that produced the weapon was closed. 250

persons lost their jobs on June 15, 1969.

In 1947 the W.L. Maxson Corporation formed the

Unimax Switch Division of the company, located in Wallingford,

CT. With changing markets and the fortunes of the company which started

in 1935, the company changed its name to the Unimax Switch

Corporation in 1975. The last reference to the Unimax Switch Corporation

in the historical record is 1987, at which time the company had no

government contacts. At this point, all vestiges of the

former W.L. Maxson Corporation that started in 1935 ceased to exist.

Table 1 - M33 and M45 Gun Mounts

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Mount Type and Company |

1942 |

1943 |

1944 |

1945 |

Total |

|

M33 |

|

|

|

|

|

|

Kimberly-Clark |

|

278 |

|

|

278 |

|

Landers, Frary & Clark |

428 |

1,454 |

|

|

1,882 |

|

Total M33 |

428 |

1,732 |

|

|

2,160 |

| |

|

|

|

|

|

|

M45 |

|

|

|

|

|

|

Kimberly-Clark |

|

2,754 |

2,019 |

|

4,773 |

|

Landers, Frary & Clark |

|

4,961 |

3,336 |

|

8,297 |

|

Total M45 |

|

7,715 |

5,355 |

|

13,070 |

|

Combined M33 and M45 Total |

|

|

|

|

15,230 |

When the M45 is mounted on a M20 trailer,

the combination was known as the M55, as seen here at the Military

Veterans Museum in Oshkosh, WI. Author's photo.

Author's photo.

The W.L. Maxson Company's New York plant won the Army-Navy "E" Award three times

during World War Two.

W.L. Maxson World War Two Production:

The company had $18,898,000 in major

contracts from the U.S. Army and U.S. Navy during World War Two.

The single largest contract was with Army Air Forces for Bomb Sight Kits

valued at $6,755,000 which was 35.7% of all contracts. This was

contract number 33038 AC4495 awarded August 1944. The contract was

for 26,000 Type X1

Reflex Sights for the M9 Norden Bombsight which allowed the bombardier a

wider field of vision in looking at the target. The unit price for

the Type X1 Reflex Sight was $259.80.

The second largest contract was awarded in April 1945 by the Army

Air Forces for $5,898,000 or 31.2% of the total contracts. This

was for oscilloscopes.

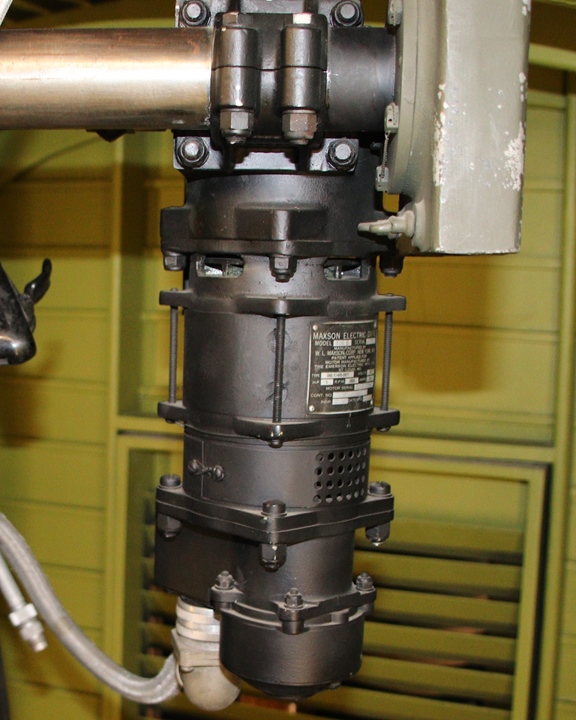

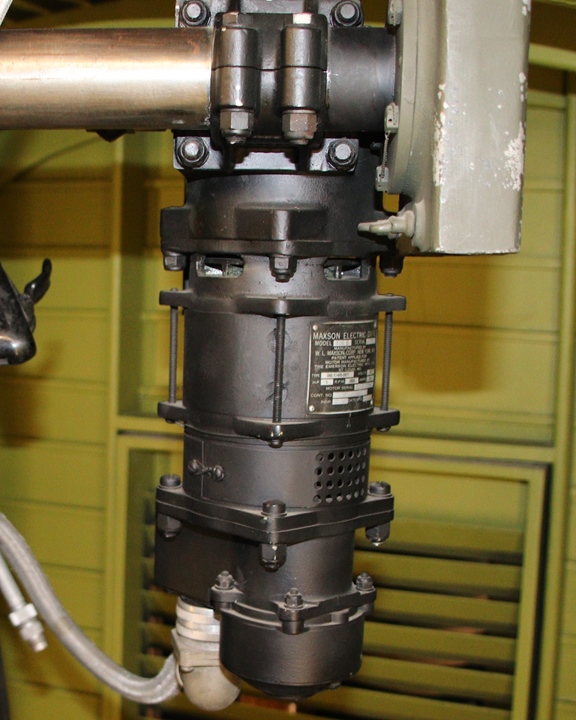

W.L Maxson also produced

15,230 Model

120A variable speed drives for the Maxson M33 and M45 Multiple Gun

Mounts and at least 1,751 azimuth drive units and 1,751 elevation drive units for the A-8

training turret.

Table 2 - W.L. Maxson Company's Major World War Two Contracts

- New York, NY Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. Table added 9-30-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Optical Equipment

- Army |

$140,000 |

7-1940 |

8-1942 |

| Ordnance

Equipment - Army |

$107,000 |

7-1940 |

10-1941 |

| Ordnance

Equipment - Army |

$77,000 |

10-1940 |

2-1942 |

| Ordnance

Equipment - Navy |

$1,235,000 |

2-1941 |

6-1943 |

| Ordnance

Equipment - Army |

$142,000 |

6-1941 |

11-1942 |

| Ordnance Material

- Navy |

$96,000 |

8-1941 |

11-1941 |

| Ordnance

Equipment - Army |

$139,000 |

10-1941 |

1-1943 |

| Optical

Instrument - Navy |

$342,000 |

2-1942 |

10-1943 |

| Equipment

Ordnance - Navy |

$346,000 |

4-1942 |

5-1943 |

| Mounts Gun

- Army |

$73,000 |

4-1942 |

7-1942 |

| Ordnance

Equipment - Army |

$182,000 |

5-1942 |

7-1943 |

| Ordnance

Equipment - Army |

$53,000 |

6-1942 |

5-1943 |

| Mounts Telescope

- Army |

$114,000 |

8-1942 |

12-1943 |

| Turrets - Army |

$100,000 |

11-1942 |

7-1943 |

| Ordnance

Equipment - Navy |

$251,000 |

11-1942 |

8-1943 |

| Research Services

- Navy |

$1,839,000 |

12-1942 |

6-1946 |

| Sight Mechanisms

- Army |

$353,000 |

8-1943 |

12-1943 |

| Ordnance

Equipment - Army |

$112,000 |

8-1943 |

2-1944 |

| Rectifiers

- Navy |

$88,000 |

9-1943 |

2-1944 |

| Elec Turret

Drives - Navy |

$193,000 |

5-1944 |

3-1945 |

| Bomb Sight Kits -

Army |

$6,755,000 |

8-1944 |

5-1945 |

| Turret Rectifiers

- Army |

$144,000 |

9-1944 |

1-1945 |

| Gun Mount

Equipment - Navy |

$119,000 |

3-1945 |

6-1945 |

| Oscilloscopes

- Army |

$5,898,000 |

4-1945 |

1-1946 |

| Total |

$18,898,000 |

|

|

Late in Word War Two the company opened a

plant in Los Angeles, CA for the production of rectifiers for both the

U.S. Army and U.S. Navy.

Table 3 - W.L. Maxson Company's Major World War Two Contracts

- Los Angeles, CA Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division. Table added 9-30-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Portable

Rectifiers - Army |

$98,000 |

9-1944 |

1-1945 |

| Rectifiers MP1011

- Navy |

$75,000 |

11-1944 |

7-1945 |

| Portable

Rectifiers - Army |

$56,000 |

5-1945 |

6-1945 |

| Total |

$229,000 |

|

|

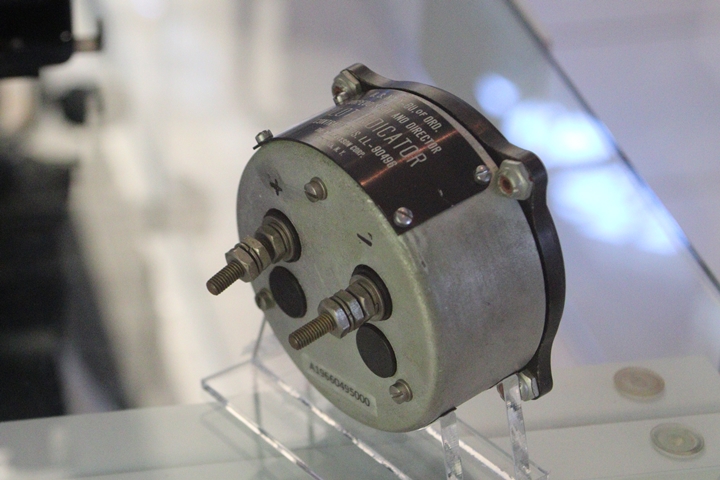

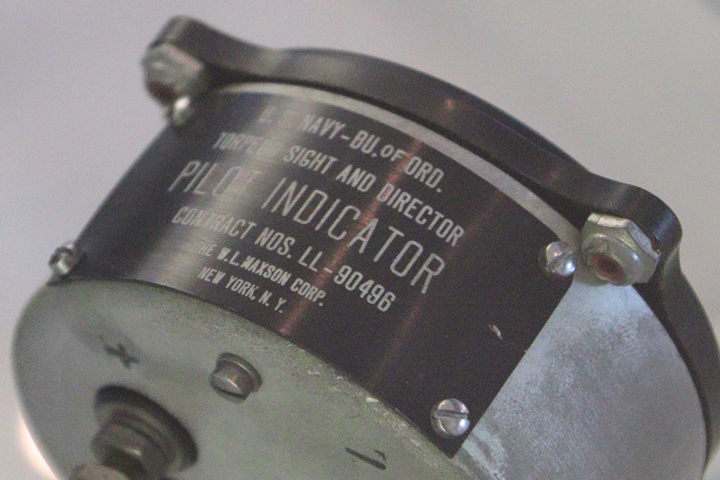

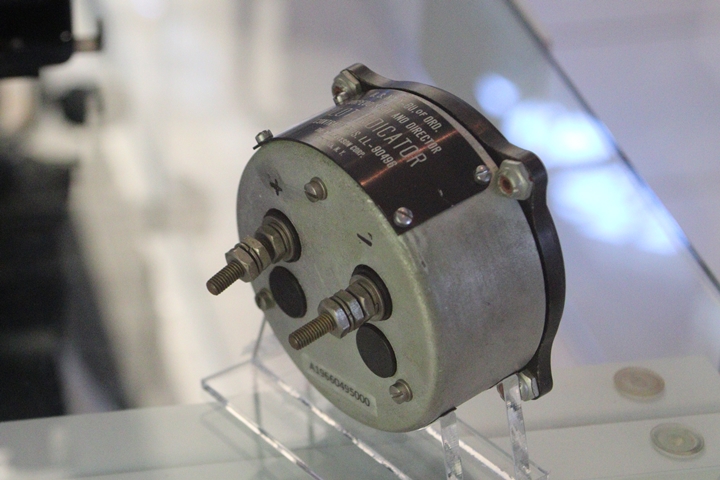

W.L. Maxson Torpedo Sight and Director:

The following seven photos were taken at the

National Air and Space Museum Steven F. Udvar-Hazy Center near

Chantilly, VA. The two items shown below were in a glass display

case along the north wall of the main hangar.

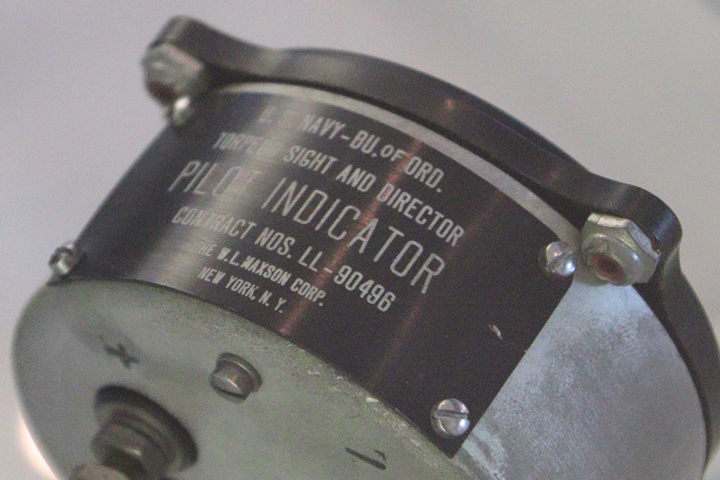

According to the information placard, this

type of aircraft torpedo sight and director was built for the British.

However, the information on the data plates show that it was produced

under contract NOS. LL-90496. This corresponds to the contract

listed in

Table 2 dated 8-1941 for $96,000. Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

It is a mystery as to whether the U.S. Navy

purchased these for its own use or for the British Navy. Author's

photo added 9-30-2022.

This pilot indicator informed the pilot

which direction to turn for an accurate torpedo launch. Author's

photo added 9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

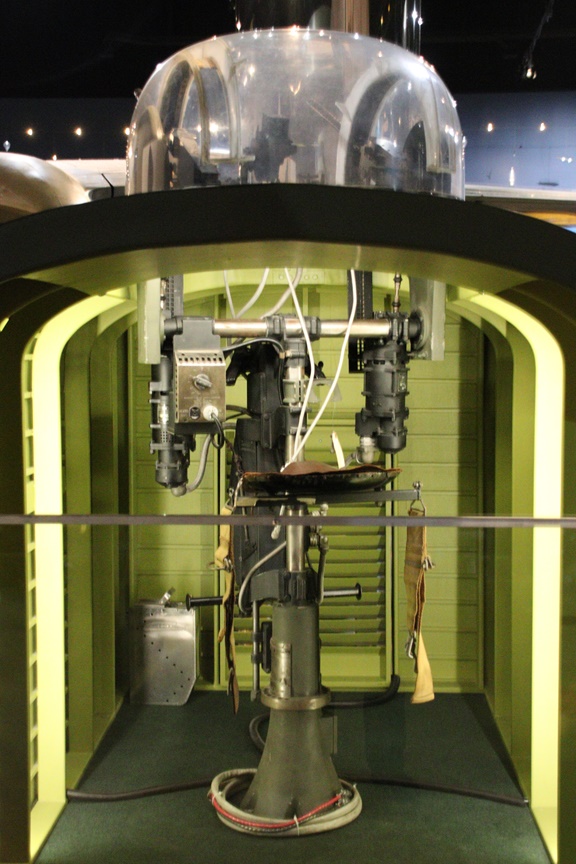

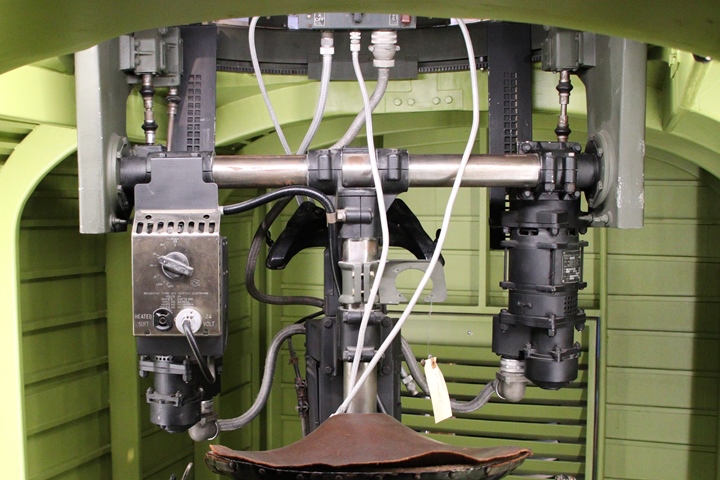

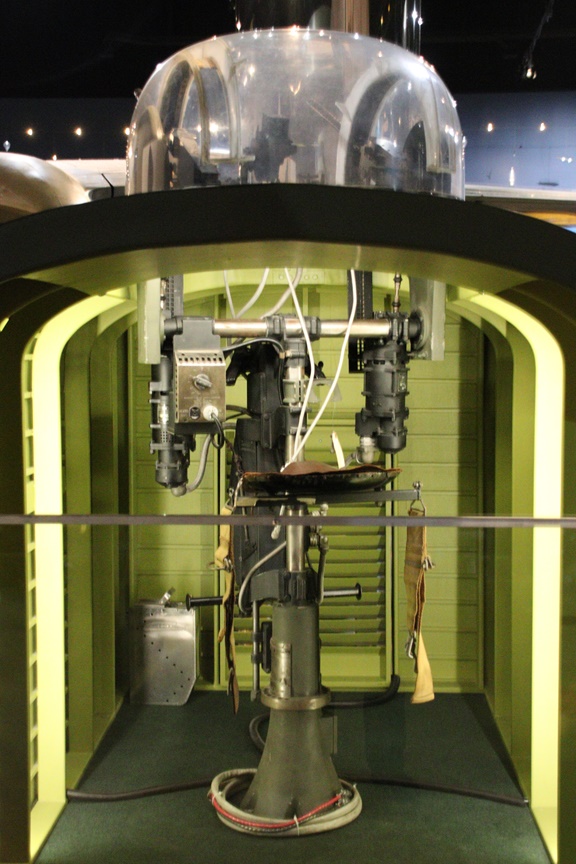

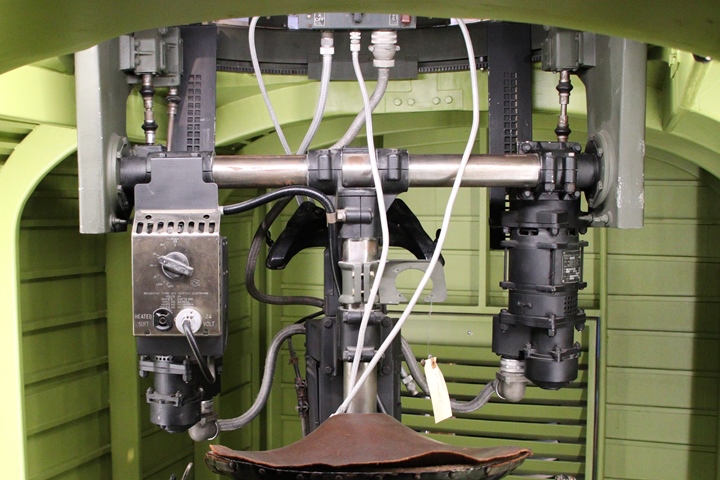

The

A-8 Training Turret: The Army Air Forces utilized a number of

AT-11s as turret gunnery trainers. These aircraft contained a

ventral turret with a Type A-8 turret. W.L. Maxson furnished the

control units for the elevation and azimuth drive motors. Based on

the serial number of the Type A-8 shown below, the company produced at

least 1,751 of each type of drive motor control system. The W.L.

Maxson drive type for the A-8 training turret was an electric drive that

utilized a pulsation field control system. The Arny Air Corps

approved this drive design for use after the company attempted several

V-belt drive systems.

In August 1941, the

Armament Branch at Wright Field contacted W.L. Maxson about providing a

turret drive for the Brewster XB2A that was being developed for the

Netherlands. The company developed a V-belt type drive system that

was found to be too heavy for the application. W.L. Maxson was

subsequently eliminated for consideration for building the turret

drives. Also, none of this type of Brewster aircraft were ever

produced for the Dutch.

In December 1941, W.L.

Maxson submitted another V-belt turret drive to the Armament Branch.

While it showed some promise, it was not adopted. Instead, the

company changed course and developed the

electric drive system that was utilized in the A-8 training turret.

This is an AT-11 with a Type A-8 training

turret installed. Author's photo added 9-30-2022.

The following photos were taken of the display

of a Type A-8 in a mockup AT-11 fuselage at the Air Zoo Aerospace &

Science Museum in Kalamazoo, MI.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

This is serial number 1751. This

serial number is evidence that W.L. Maxson provided at least 1751 elevation and azimuth

drive controls for the Type A-8. Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

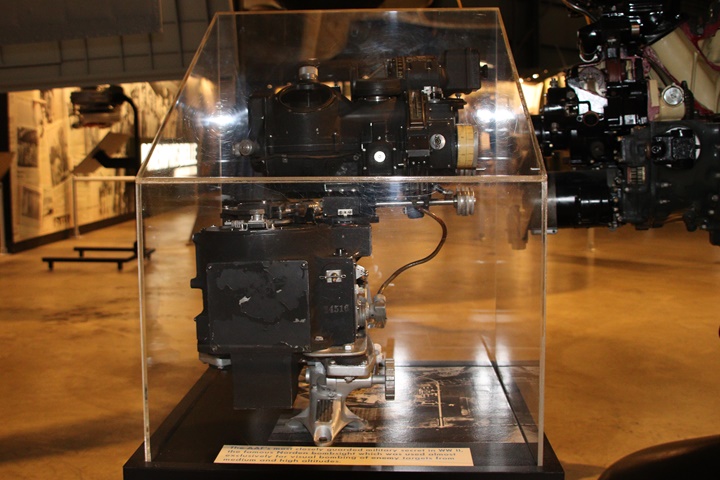

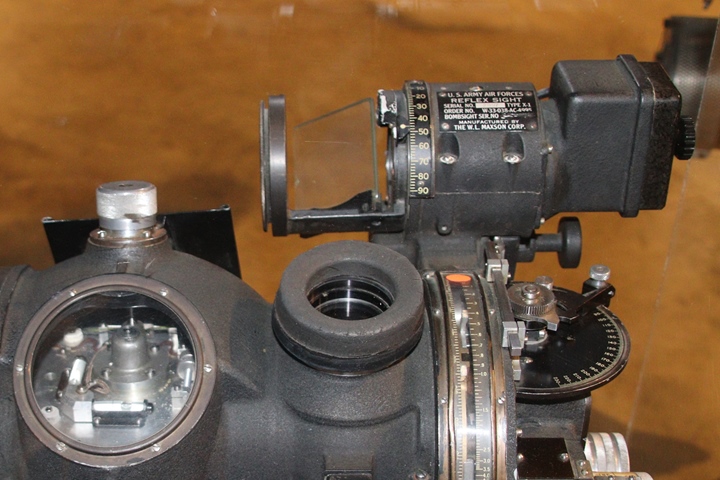

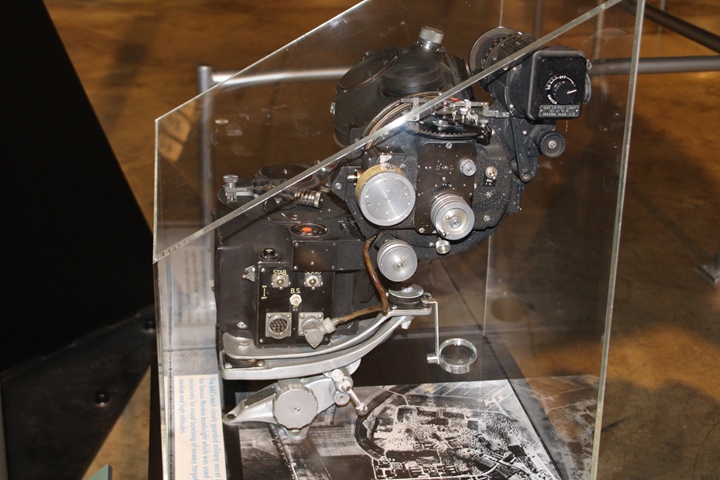

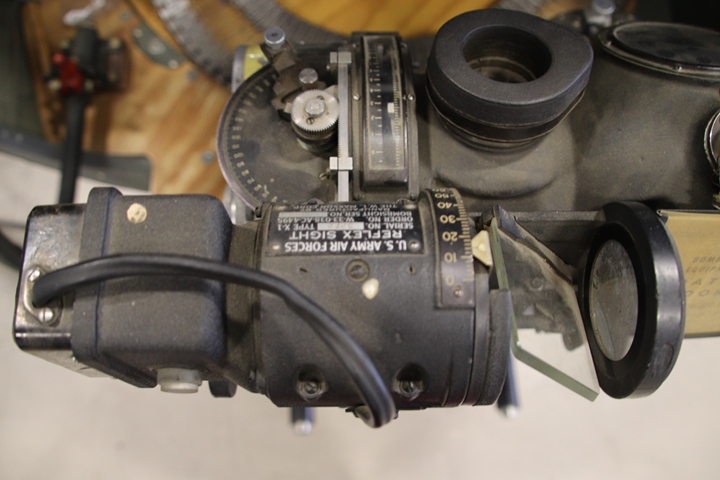

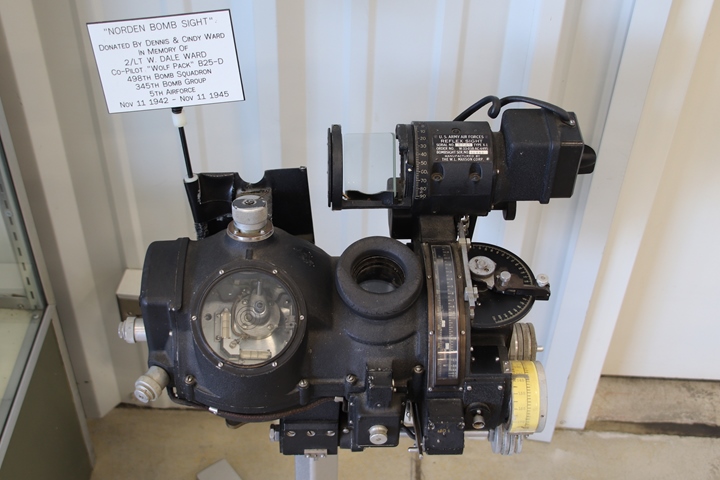

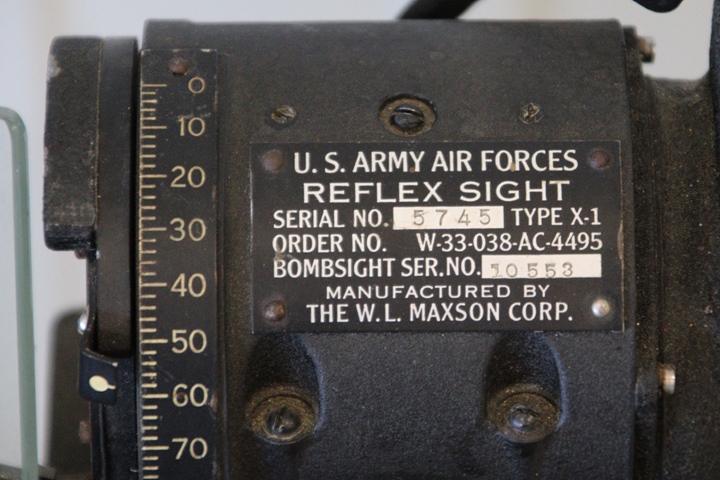

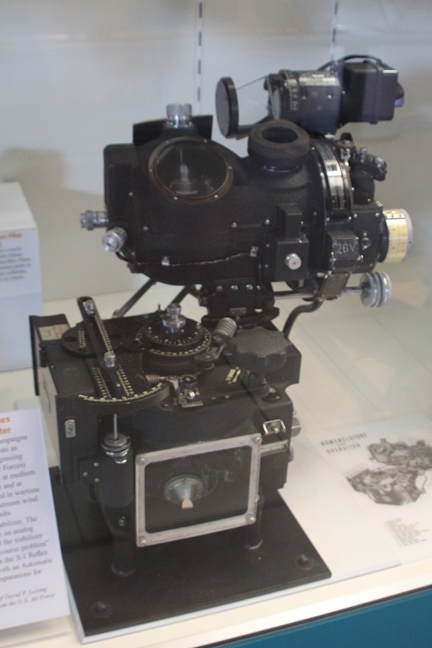

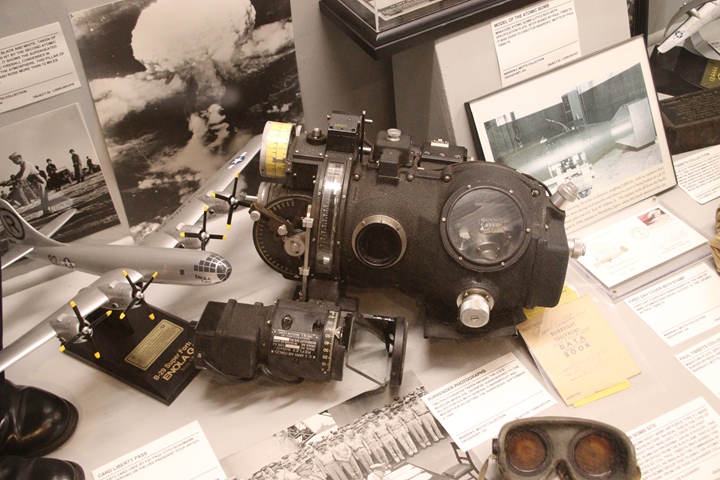

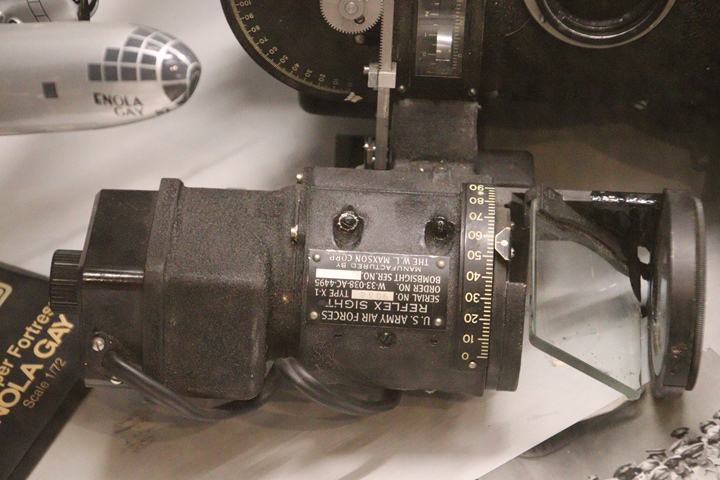

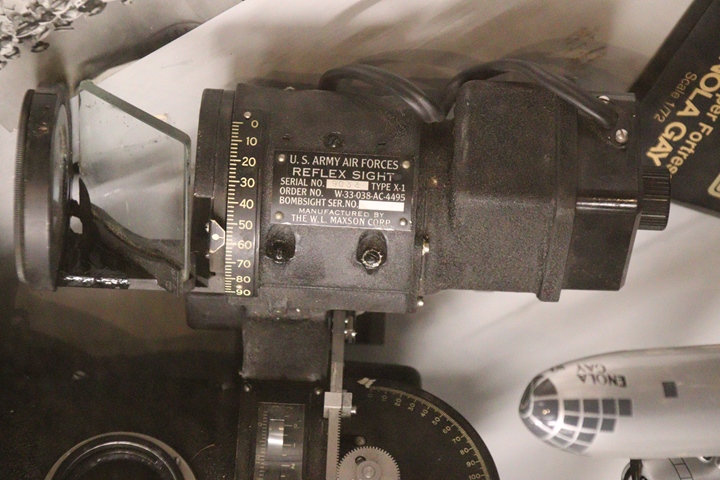

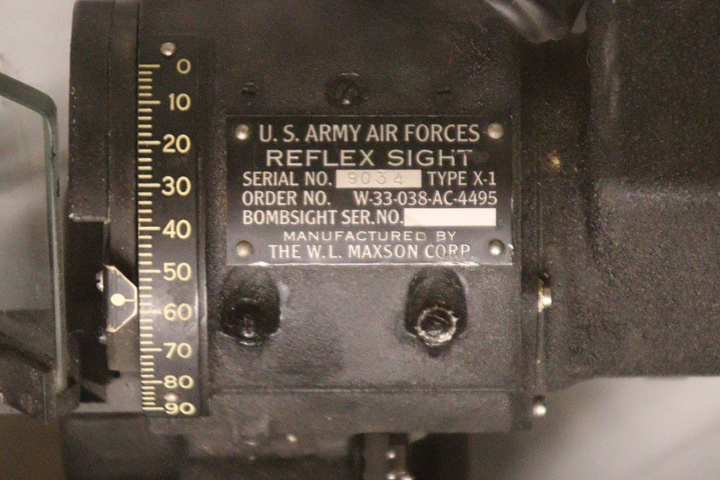

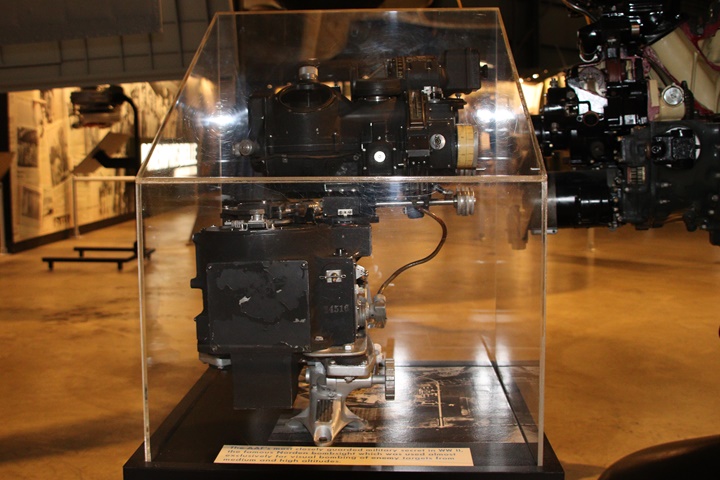

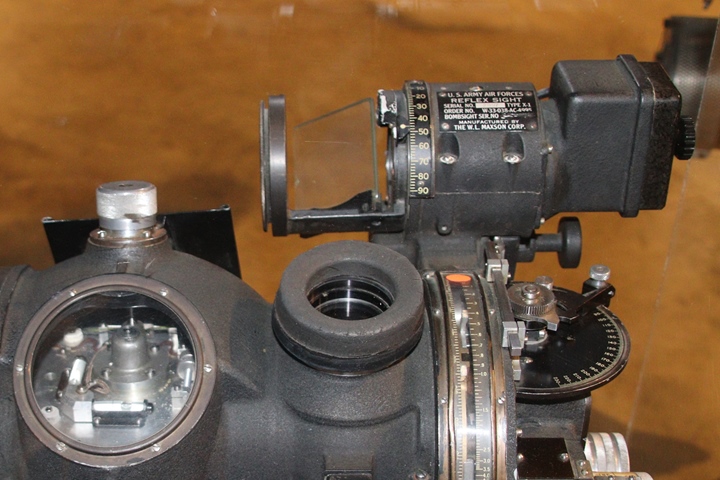

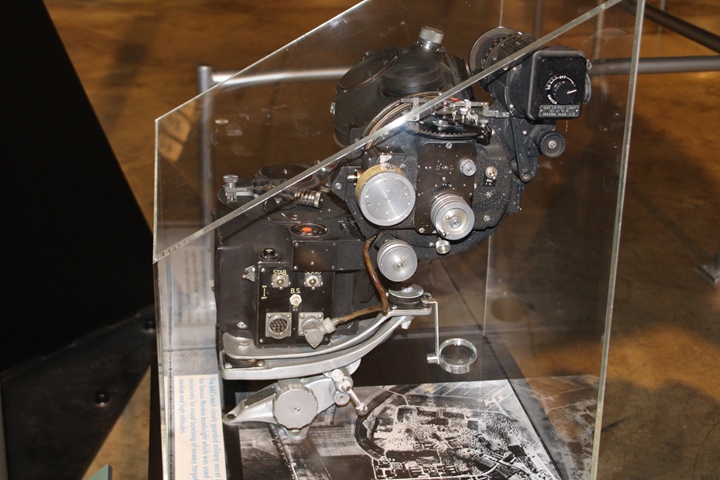

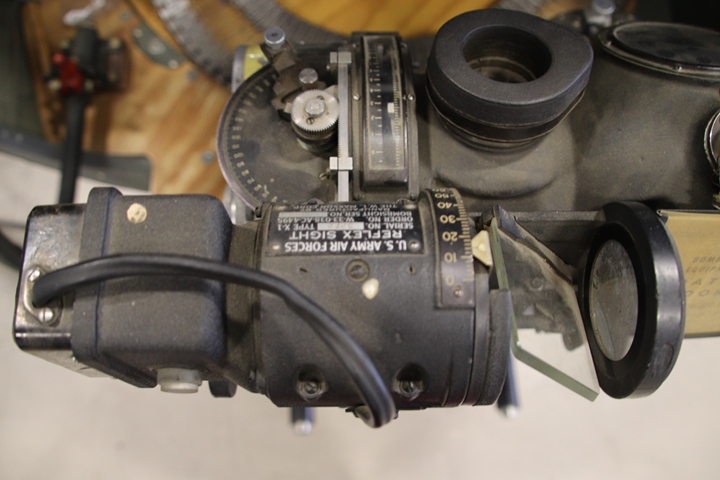

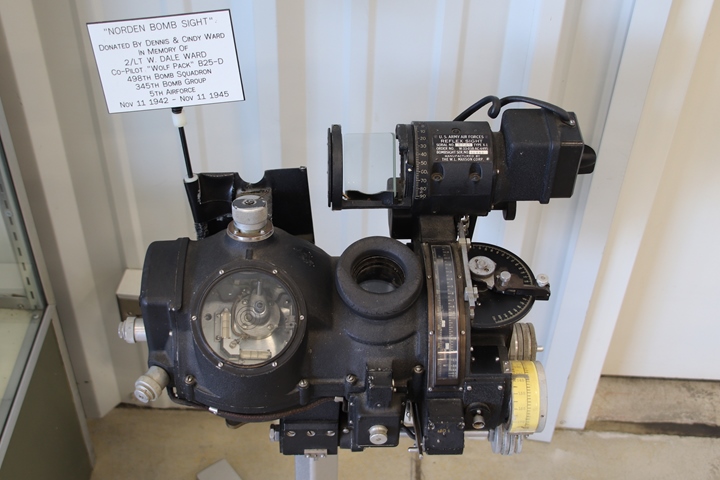

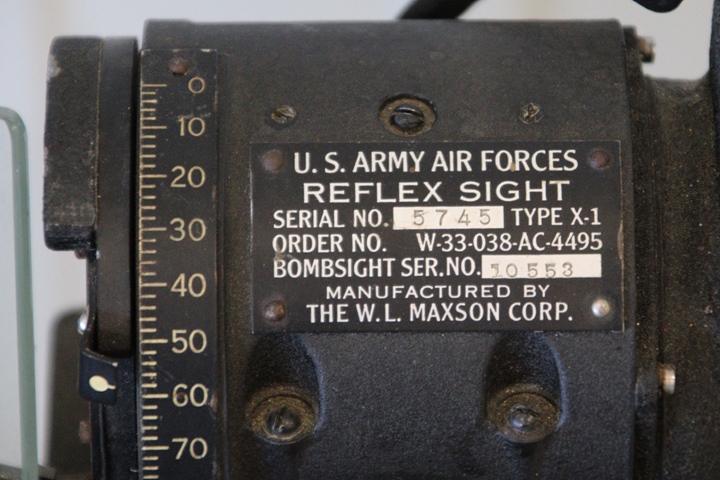

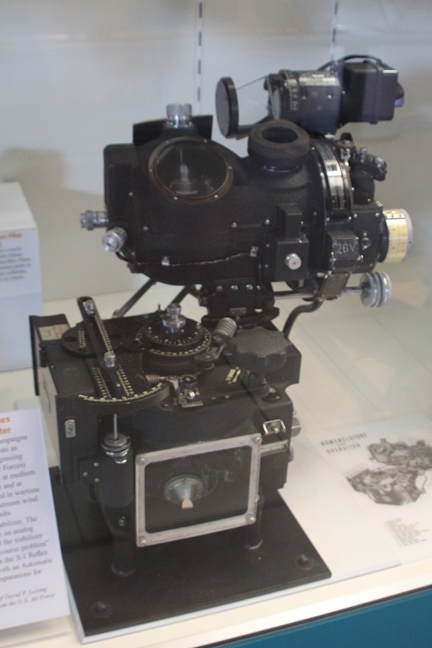

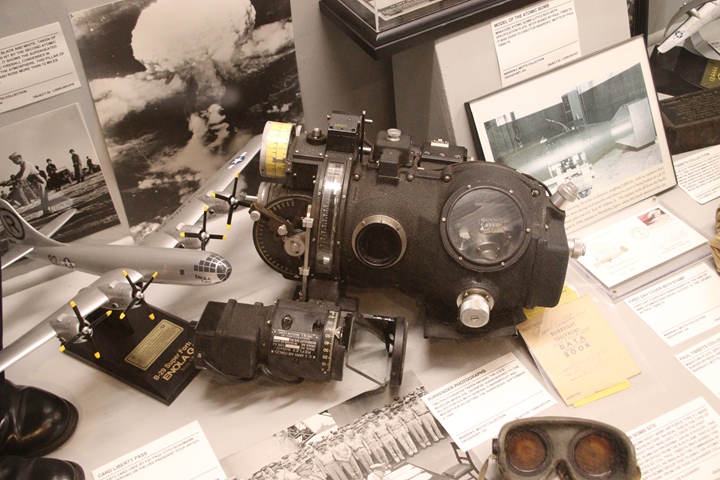

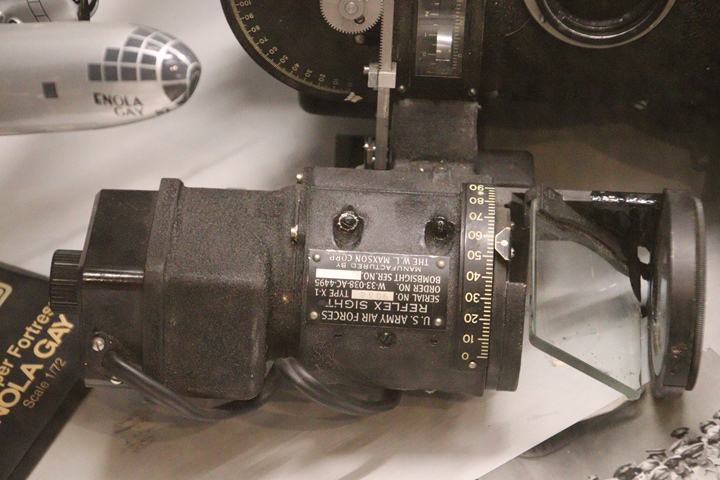

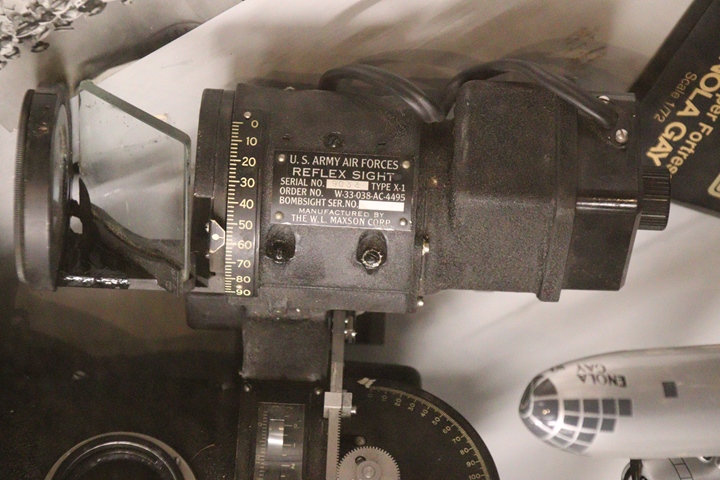

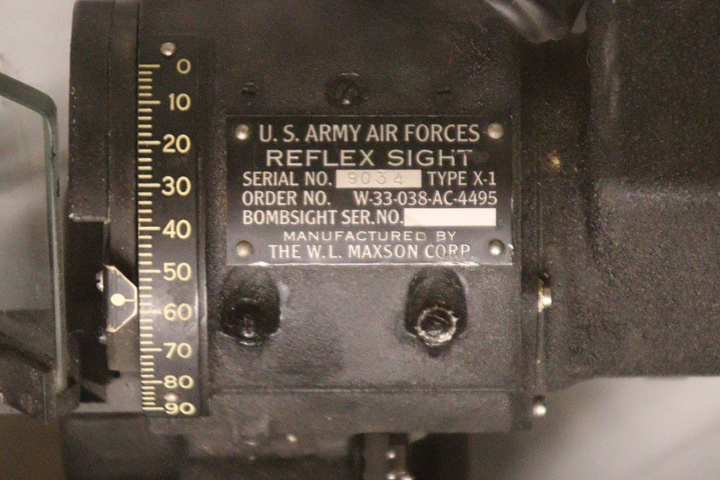

Type X1

Reflex Sight for the M9 Norden Bombsight:

These were built for the U.S. Army Air

Forces on contract number 33038 AC4495 awarded August 1944.

This was W.L. Maxson's largest contract of the war for $6,755,000.

These were a late war addition to the Norden bombsight

which allowed the bombardier a wider field of vision in looking at the

target. The original order was for 26,000 units. The unit price

for the Type X1 Reflex Sight was $259.80. So far in my

research, the highest serial number I have found in museum displays is

10179.

It should be noted that

not all Norden M9 bombsights on displays in museums have the Type X1

Reflex Sight attached.

This M9 Norden Bombsight is on display at the National Museum of United

States Air Force. Author's photo.

The

W.L. Maxson

X1 Reflex Sight is

in

the upper right corner of the photo.

Author's photo.

The reflex sight was a late addition to the basic bombsight to assist

the bombardier in finding the target from high altitudes in overcast

European skies. The reflex sight gave the bombardier a wider angle

of view than the telescope through the eye piece. The X-1 reflex

sight projected the view onto the angled piece of glass. This was

a World War Two use of heads-up display that is now used in aircraft

and automobiles. This was cutting-edge high technology of the era.

Author's photo.

This is Reflex Sight serial number 2897. Author's photo.

Author's photo.

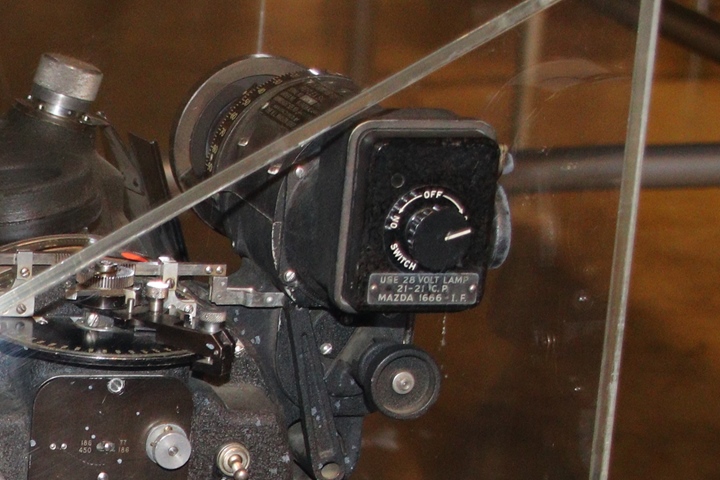

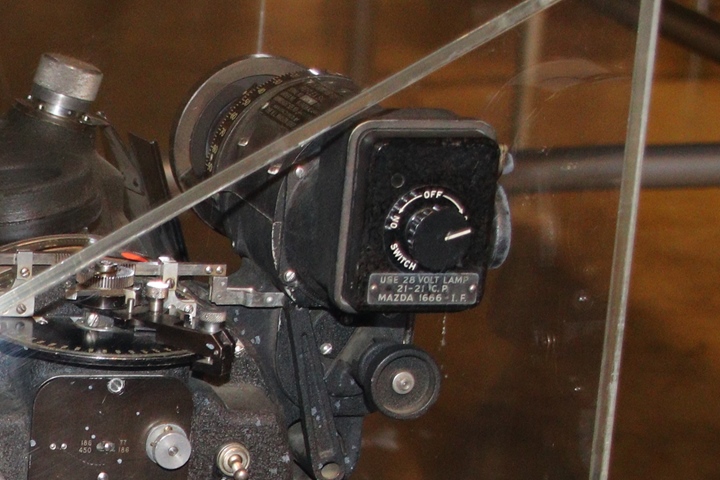

Mazda

was a trade name for a GE light bulb. By turning the knob, the

bombardier could control the amount of light on the heads-up display.

Author's photo.

This Norden M9 bombsight with W.L. Maxson X1

Reflex Sight is mounted in the bombardier's position of a B-17G being

rebuilt at the Champaign Aviation Museum in Urbana, OH. Author's

photo added 9-30-2022.

Its position in the front of the aircraft

allows for different views of the X1 Reflex Sight. Author's photo

added 9-30-2022.

Author's photo added 9-30-2022.

This X1 is serial number 3272.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

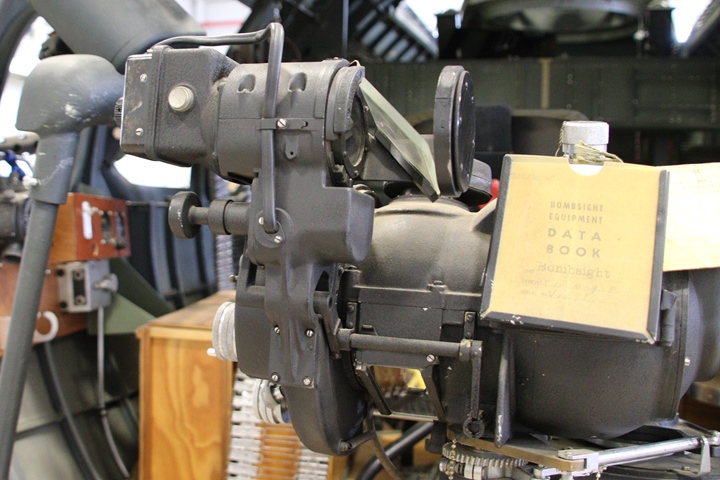

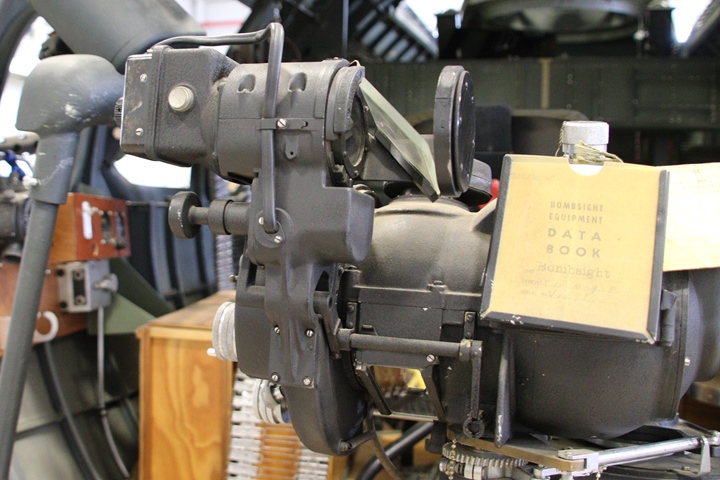

This

Norden bombsight on display at the Tri-State Warbird Museum in Batavia,

OH has a Maxson

X-1 Reflex Sight attached. Author's photo.

This is Reflex Sight serial number 5745 and bombsight serial number 50553.

Maxson did not build the M9, so the serial number for the bombsight must

have been added at the bombsight manufacturer. Author's photo.

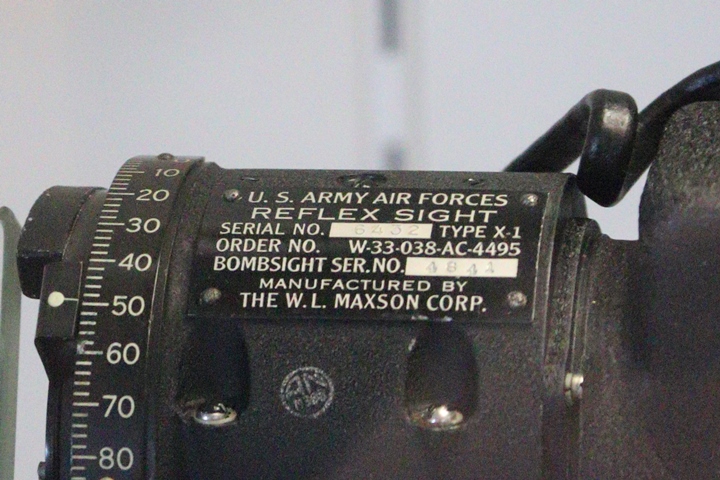

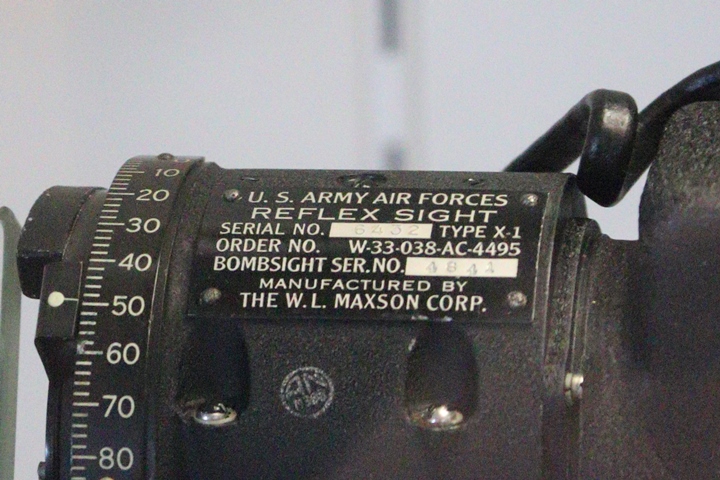

This Norden bombsight with the Type X-1

Reflex Sight is on display at the National Air and Space Museum Steven

F. Udvar-Hazy Center. Author's

photo added 9-30-2022.

It is serial number 6432. Author's

photo added 9-30-2022.

Another

X-1 can be found at the Motts Military Museum in Groveport, OH.

Author's photo.

Author's

photo.

The glass for the heads-up display can be clearly seen in this photo.

Author's photo.

This example is serial number 9034. Author's photo.

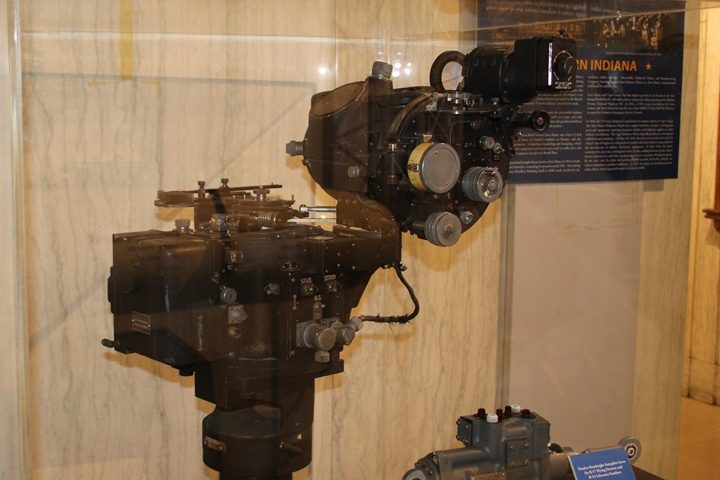

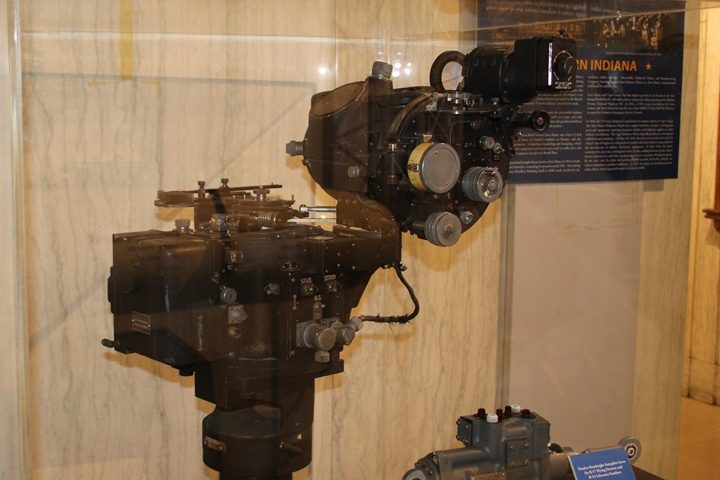

This

Norden M9 bombsight was built by Lukas- Harold in Indianapolis, IN.

It is on display at the Indiana War Memorial in downtown Indianapolis, seven miles from where it was built. Author's photo.

Author's photo.

This

view allows a look at the back side of the X-1. Author's photo.

This view looks down at the Reflex Sight. Author's photo.

Serial

number 10179 indicates Maxson built at least this many

reflex sights. Author's photo.

M33 and M45 Gun Mount Hand Grip Control

Units: While the W.L. Maxson Company did not built the M33 and

M45 turrets, the company did produce the hand grip control units that

the gunner used to aim the turret. W.L. Maxson provided 17,390 of

these units.

This halftrack and Maxson M45 turret saw

combat with the U.S. Army in

Korea and French forces in Vietnam. Owner Mark Koloc rescued it

from the French controlled Horn of Africa while serving there as a Lt.

Colonel with the U.S. Army. The "African Queen," as this vehicle

has been named, was on temporary display at the National Museum of the

United States Air Force for a year. Author's photo added

9-30-2022.

Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

The next two photos of the "African Queen"

were taken at the Findlay, OH Military Show. Mr. Kolac allowed me

access to the M45 turret. I was able to photograph the Maxson hand

control unit. Author's photo added 9-30-2022.

Author's photo added 9-30-2022.

The New York City W.L. Maxson Operations:

World War Two era W.L. Maxson "Help

Wanted" advertisements gave several addresses in New York City. One

was at 423 9th Avenue at 34th Street.

This is the current street view of the location on 9th Avenue.

While the building has been repurposed into several commercial

businesses, the yellow brick at the top of the building indicates this

is an older building and could have been the location of the W.L. Maxson factory.

Photo courtesy of Google Maps added 9-30-2022.

This photo shows the view from around the corner on West

34th Street. Photo courtesy of Google Maps added 9-30-2022.

Another address given in a job advertisement and also from a quarterly

dividend report is 460 West 34th Street. This may have been the

corporate headquarters. Photo courtesy of Google Maps added

9-30-2022.

44 East 23rd Street in Manhattan is another location given for job

applicants to go for a W.L. Maxson job during World War Two.

The current address for the building under restoration is now 46 East

23rd Street while the brown building to the right of it is 42.

Most likely, W.L. Maxson had a store front in the larger building on the left with

an address of 44 East 23rd Street.

Photo courtesy of Google Maps added

9-30-2022.

The Old Forge, PA, Maxson Electronics

Plant:

This plant was built in Old Forge, PA, in 1951 and had 150,000 square

feet of floor space. Between 1951 and 1969 when it closed, it

built a number of different electronics devices. It produced

communication, microwave, radar, and missile guidance systems. In

1961, it also developed a three-dimensional radar for the Federal

Aviation Administration.

Photo courtesy of Google Maps added

10-12-2022.

This AGM-12C Bullpup air-to-ground missile is on display at the National

Museum of the United States Air Force in Riverside, OH. The

information placard associated with this display notes that Maxson

Electronics produced most of the 4,600 AGM-12Cs built. However,

when the contract expired in 1969 for the building of this missile at

the Old Forge, PA plant, there were no follow-up contracts, and the

plant closed.

Author's photo added 10-12-2022.

|