|

Metal Mouldings Corporation During World War Two

Detroit, MI

1924 - 1959

This page added 6-20-2023.

In 1924, Mr. Clarence P. Chamberlin, then 35

years old, founded the Metal Mouldings Corporation of Detroit, MI.

Mr. Chamberlin's new company produced metallic trim components for the

growing automotive manufacturers in the Detroit area. During World

War Two, the company had $7,602,000 in major contracts with the U.S.

Navy for bomb shackles and racks. Table 1 shows that with the

exception of Navy contract number ORD-6611 for bomb lug removers the

other seven contracts were for bomb rack, shackles, and parts.

Mr. Chamberlin remained the president of the

company during its 35 year life time. At its peak, the company

employed 700 workers making trim parts for various auto companies.

At the end of July 1959, Mr. Chamberlin announced that his company would

cease operations on August 31, 1959. His company, like many other

automobile component suppliers, were caught in a squeeze between rising

material costs, and a customer base that would not pay for the increased

cost of materials. When his company closed, 275 workers lost their

jobs.

I understand Mr. Chamberlin's pain and

dilemma. For many year, I worked for a major automobile component

supplier that was also squeezed between rising material costs and our

main customer that would not let us increase prices. Stainless

steel is the one I remember in particular. Its cost was going

through the roof, and we lost money on every stainless fuel injection

system we shipped to the customer. In the end, most of our company

ended up like Metal Mouldings Corporation did, out of business. I

was lucky and was able to take an early retirement. Many others

weren't so lucky.

I discovered the existence of the Metal

Mouldings Corporation while visiting the National Naval Aviation Museum

in May 2023. I was unaware of its existence until I found two Mark

51 Mod 11 bomb rack under the wings of the TBM Avenger on display.

Further research showed that the Metal Mouldings Corporation was an

unknown and undocumented Detroit company that made significant

contributions to the winning of World War Two. Even the Detroit

Historical Society overlooked the Metal Mouldings Corporation and has

not listed it on its Detroit Arsenal of Democracy website.

This page recognizes the contribution of the

Metal Mouldings Corporation that helped win World War Two.

Table 1 - Metal Mouldings

Corporation's Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Bomb Racks - Navy

Ordnance |

ORD-3705 |

$131,000 |

5-1943 |

10-1943 |

| Bomb

Shackles - Navy Ordnance |

ORD-3515 |

$335,000 |

5-1943 |

5-1944 |

| Bomb Racks

- Navy Ordnance |

ORD-3931 |

$1,768,000 |

6-1943 |

3-1945 |

| Bomb Racks

- Navy Ordnance |

ORD-4183 |

$1,204,000 |

7-1943 |

8-1944 |

| Bomb Lug

Removers - Navy Ordnance |

ORD-6611 |

$176,000 |

7-1944 |

11-1944 |

| Bomb Racks

MK 51 - Navy Ordnance |

ORD-7737 |

$1,980,000 |

12-1944 |

7-1945 |

| Bomb Racks

MK 51 - Navy Ordnance |

ORD-9270 |

$1,620,000 |

6-1945 |

12-1945 |

| Bomb Rack

Parts - Navy Ordnance |

ORD-9278 |

$388,000 |

6-1945 |

12-1945 |

| Total |

|

$7,602,000 |

|

|

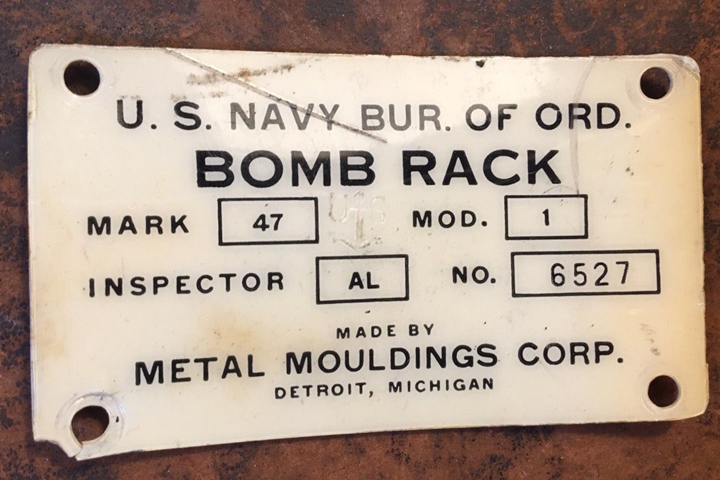

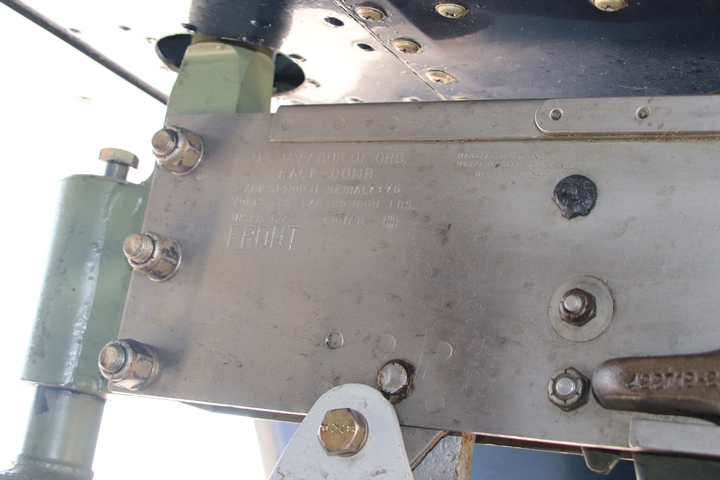

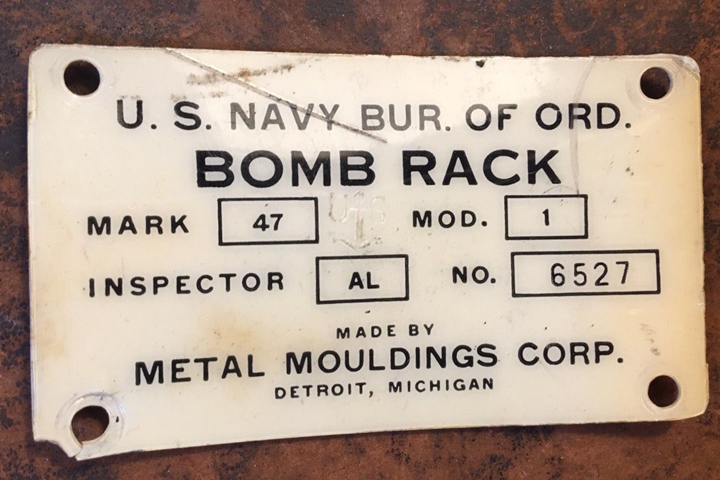

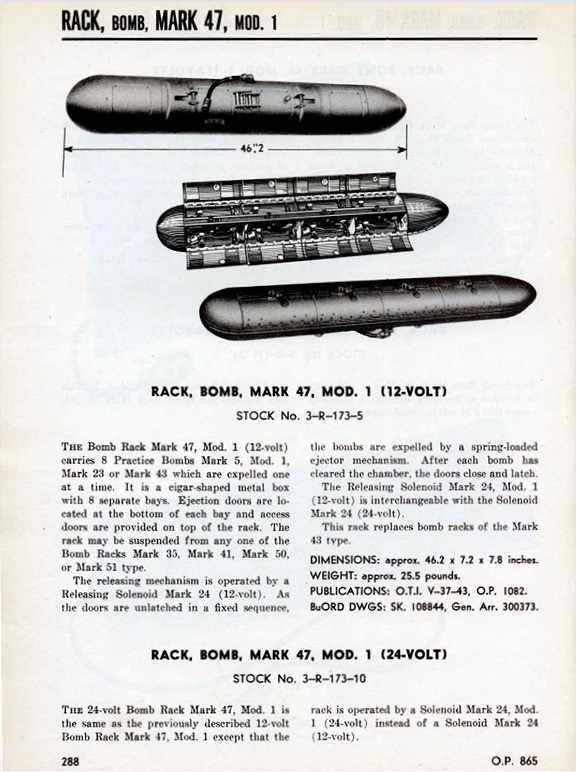

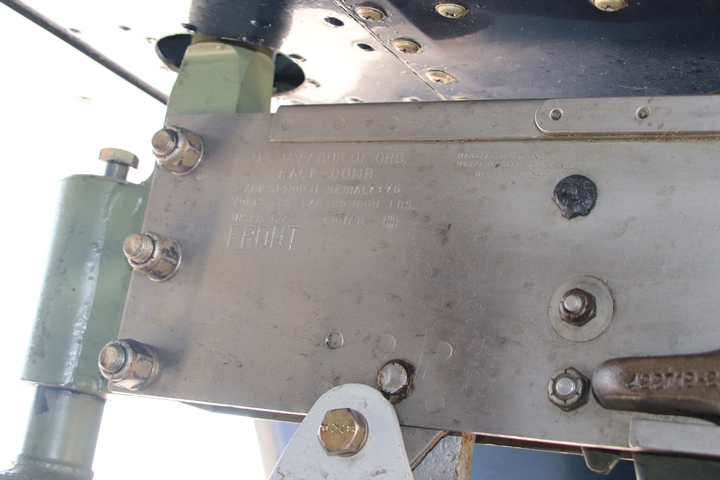

This Metal Mouldings Corporation data plate

shows that the company also built the Mark 47 bomb rack. The

serial number indicates it made at least 6, 527 of them. The Mark

47 may well have been built under Navy Ordnance contract numbers

ORD-3705, ORD-3931, and ORD-4183.

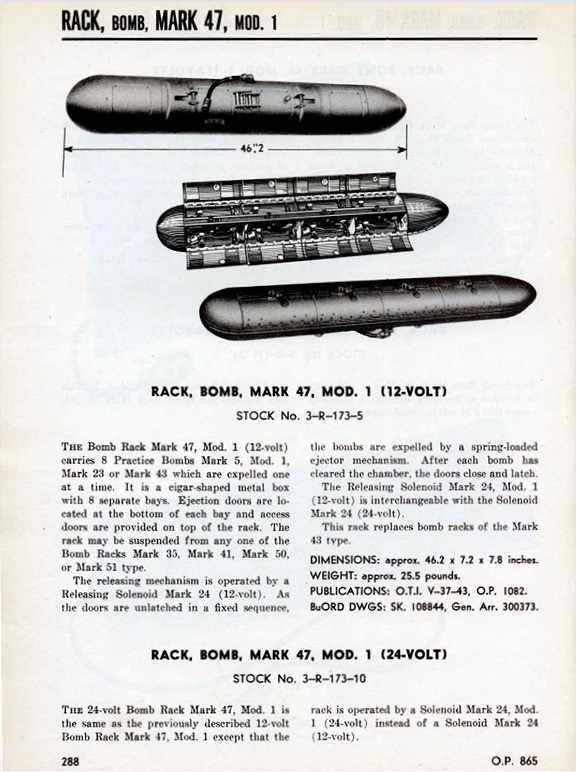

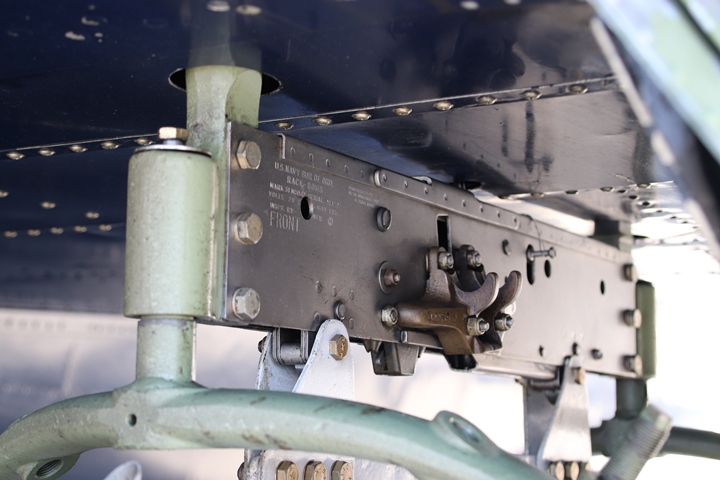

This images shows that the Mark 47 was a

rather complex device.

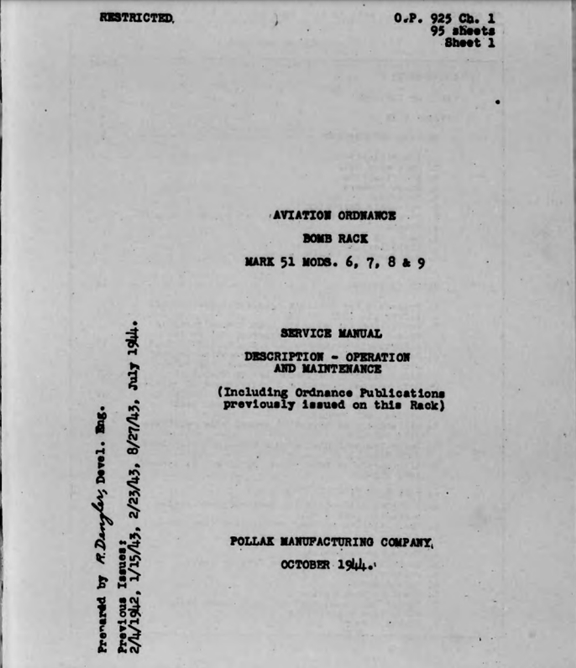

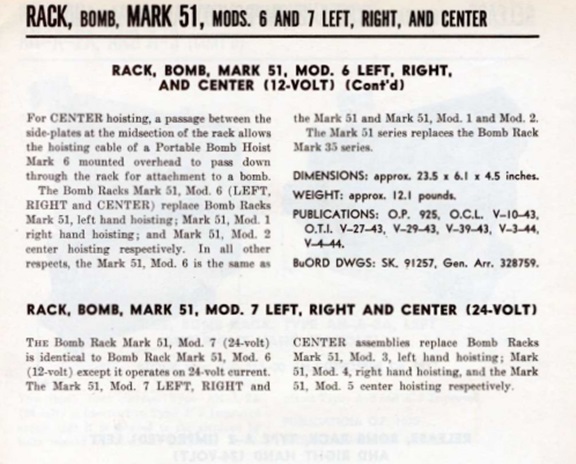

This is an interesting photo, as it shows

that Metal Mouldings Corporation originally subcontracted to the Pollak

Manufacturing Company of Arlington, NJ for the Mod 7 version of the Mark

51 bomb rack. Pollak was a large producer of ordnance items for

primarily the U.S. Navy during World War Two. It was awarded its

first Navy contract for bomb racks in October 1940. It was also

the lead company on the Mark 51 bomb rack and wrote the manual on it.

Apparently, with all of the contracts it had, Pollak did not have the

manufacturing capacity to produce the Mark 51. Instead, it found

Metal Mouldings to make the Mark 51s. Note the "P" inside the

circle with wings. This indicates that it is Pollak contracted

bomb rack.

This image shows the cover page for the Mark 51 manual authored by the

Pollak Manufacturing Company.

This TBM Avenger is on display at the

National Naval Aviation Museum in Pensacola, FL. On each wing

there is a replica 500 lb. bomb mounted to the wing by a Metal Mouldings

Corporation Mark 51 Mod 11 bomb rack. Note that there is no

barrier around the aircraft. Actually, none of the aircraft on

display at the Naval Aviation Museum have barriers around them.

This is very unusual; as most, if not all, other aviation museums have a

barrier to keep the spectators from damaging the aircraft. For me,

this allowed me to get up close and photograph the bomb racks.

Author's photo.

This is the bomb and bomb rack underneath

the port wing. Author's photo.

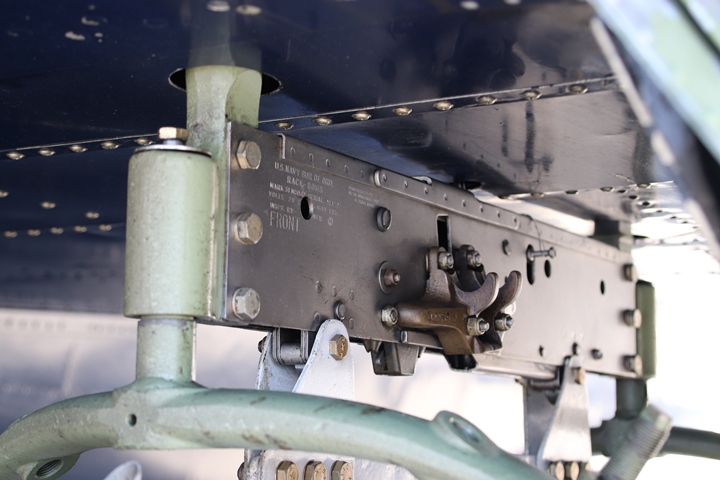

This image shows how the bomb rack attaches

to the wing and the bomb to the Mark 51 bomb rack. Author's photo.

This is serial number 9010. Note the

two "M"s stacked on top of each other inside a circle. This

indicates it is a Metal Mouldings contracted bomb rack. Author's

photo.

This is the bomb rack and bomb from the

starboard wing. Author's photo.

Author's photo.

This is serial number 39464. This is

the highest serial number I have found for a Metal Mouldings Mark 51 Mod

11 bomb rack. The indicates the company made at least 38,464 of

these bomb racks. Author's photo.

Nine days later and 767 miles to the

northwest of the Naval Aviation Museum, I was at the annual TBM Reunion

and Salute to Veterans at the airport in Peru, IL. Here I would

find two more Metal Mouldings Corporation-built Mark 51 Mod 11 bomb

racks. With four of these bomb racks now identified, I decided I

need to recognize the company for it contribution to winning World War

Two. Author's photo.

For this particular TBM, the 100 gallon drop

tanks were mounted to the wing with bomb racks constructed by Metal

Mouldings Corporation. Author's photo.

Author's photo.

Author's photo.

Early in the morning, I was able to

photograph the 100 gallon fuel tanks and the Mark 51 bomb racks.

This is from the starboard side of the aircraft. Author's photo.

This is serial number 7376 The two

"M"s stacked on top of each other inside the circle can readily be seen

in this photo. Author's photo.

This is the port side 100 gallon drop tank.

Author's photo.

Author's photo.

This is serial number 26412. Author's

photo.

Now that I know what I am looking for, I

expect to find more Metal Mouldings Corporation bomb racks on other U.S.

Navy aircraft at other museums and aviation events. I will add

photos of those as I find them.

|