|

Delta

Electric Company in World War Two

Marion, IN

1913-1964

1964-1968 as a division of Novo Industrial Corporation

1968-1977 as a division of United Filtration Corporation

1977-1978 as part of Halle Industries

This page updated 10-27-2022.

An American Auto

Industry in World War Two Special Edition

The Delta Electric Company moved from Chicago,

IL to Marion, IN

in 1916, after controlling interest in its stock was

purchased by several Marion businessmen. Throughout its history,

the company's main focus was portable lighting products. The

company produced the first battery-powered handheld lantern. Other

civilian products included flashlights, lanterns, and

lighting for bicycles and vehicles made by the American Auto

Industry in the 1930s. During both World Wars, Delta Electric built

lanterns, flashlights, and other lighting devices for the U.S. Army and

Navy.

The Delta Electric Company was located at 33rd

and Nebraska Streets in Marion, IN. The factory is no longer at

this corner. Three of the corner lots are empty with the fourth

being a building too small to have been the Delta factory.

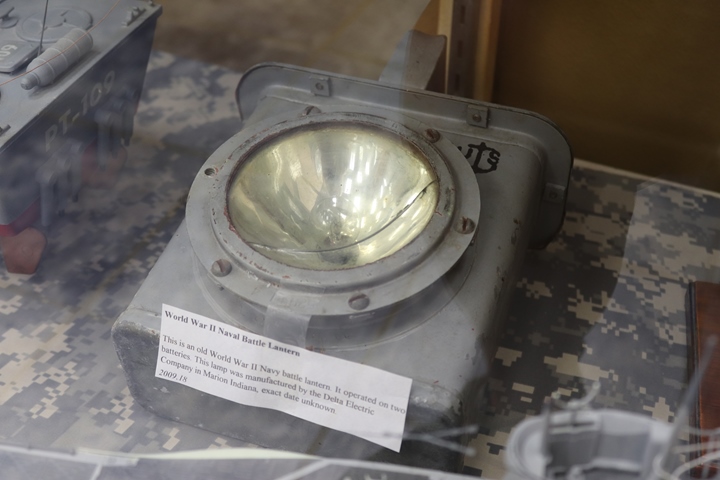

This handheld battery-powered lantern was

produced by Delta Electric Company for the U.S. Navy during World War One.

The Type F lantern has an aluminum body and rubber gaskets to make it

watertight.

Delta Electric Company World War Two

Products: The U.S. Navy purchased watertight lanterns and

flashlights for emergency lighting on Navy ships. The company also

made life preserver lights, signal gun lights, life raft float lights,

blinker lamps, electrical boxes, running lights for ships, and battle

lamps. For the U.S. Army, Delta built signal gun lights, beach

debarkations marker lights, and parachute cargo dropping lights.

For either service, it made aircraft gunnery tow target lamps, aircraft

recognition lights, and flashing flares. Delta produced 70,945

headlights for bicycles produced for the U.S. military. The

company also built headlight plugs on early World War Two era

half-tracks.

During World War Two, the company had $8,109,000 in major

military contracts from the U.S. Army, U.S. Navy, and the Maritime

Commission.

Table 1 - Delta Electric Company's

Major World War Two Contracts

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. Table added 4-29-2022. |

|

Product - Customer |

Contract Amount |

Contract Awarded

Date |

Completion

Date |

| Lanterns - Navy |

$283,000 |

11-1941 |

5-1942 |

| Electrical

Equipment - Navy |

$926,000 |

12-1941 |

2-1943 |

| Lanterns Electric

- Army |

$101,000 |

2-1942 |

7-1942 |

| Controls Box -

Army |

$153,000 |

3-1942 |

7-1942 |

| Lanterns Electric

- Navy |

$187,000 |

4-1942 |

7-1942 |

| Lanterns Electric

- Navy |

$113,000 |

4-1942 |

7-1942 |

| Lamp Assemblies -

Army |

$460,000 |

4-1942 |

8-1942 |

| Lanterns Electric

- Army |

$287,000 |

7-1942 |

4-1943 |

| Lanterns Electric

- Navy |

$91,000 |

8-1942 |

1-1943 |

| Lanterns - Army |

$80,000 |

11-1942 |

6-1943 |

| Lights - Navy |

$86,000 |

12-1942 |

4-1943 |

| Lanterns Electric

- Army |

$115,000 |

1-1943 |

6-1943 |

| Lanterns Electric

- Navy |

$144,000 |

1-1943 |

8-1943 |

| Lanterns - Navy |

$58,000 |

1-1943 |

5-1943 |

| Lanterns Electric

- Navy |

$182,000 |

2-1943 |

8-1943 |

| Lanterns Electric

- Navy |

$177,000 |

2-1943 |

3-1943 |

| Lights -

Signaling |

$151,000 |

2-1943 |

12-1943 |

| Flashlights -

Army |

$62,000 |

2-1943 |

4-1943 |

| Lifesaving

Equipment - Navy |

$52,000 |

4-1943 |

6-1943 |

| Flash Light

Equipment - Army |

$70,000 |

6-1943 |

6-1943 |

| Flashlights -

Navy |

$752,000 |

8-1943 |

6-1944 |

| Ship Emergency

Lights - Navy |

$70,000 |

8-1943 |

12-1944 |

| Electric Fixtures

- Navy |

$148,000 |

9-1943 |

2-1944 |

| Electric

Flashlights - Navy |

$81,000 |

10-1943 |

3-1944 |

| Electric Signal

Lights - Navy |

$168,000 |

11-1943 |

10-1944 |

| Electric

Flashlights - Navy |

$218,000 |

2-1944 |

6-1944 |

| Flashlights -

Navy |

$69,000 |

3-1944 |

9-1944 |

| Lantern Converter

Sets - Army |

$83,000 |

3-1944 |

6-1944 |

| Lantern Converter

Sets - Army |

$209,000 |

3-1944 |

12-1944 |

| Life

Preserver Lights - Army |

$199,000 |

3-1944 |

9-1944 |

| Hand Lanterns -

Maritime Commission |

$71,000 |

4-1944 |

10-1944 |

| Electric Hand

Lanterns - Army |

$405,000 |

4-1944 |

4-1945 |

| Electric Lanterns

- Navy |

$320,000 |

5-1944 |

10-1944 |

| Flashlights -

Maritime Commission |

$88,000 |

5-1944 |

9-1944 |

|

Gasoline Lantern Parts - Army |

$169,000 |

5-1944 |

10-1944 |

| Electric

Signaling Lamps - Navy |

$220,000 |

7-1944 |

1-1945 |

| Signal Generators

- Army |

$78,000 |

8-1944 |

12-1944 |

|

Electric Flashlights - Navy |

$62,000 |

9-1944 |

1-1945 |

| Life

Preserver Lights - Army |

$67,000 |

10-1944 |

6-1945 |

| Electric Lanterns

- Navy |

$51,000 |

12-1944 |

2-1946 |

| Lantern Relay

Assys - Navy |

$94,000 |

12-1944 |

4-1945 |

| Electric Lanterns

- Navy |

$162,000 |

1-1945 |

5-1945 |

| Lanterns MX290 -

Army |

$168,000 |

2-1945 |

6-1945 |

| Life Lights -

Army |

$56,000 |

2-1945 |

8-1945 |

| Electric Lanterns

- Navy |

$82,000 |

3-1945 |

4-1945 |

| Lanterns MX290 -

Army |

$146,000 |

5-1945 |

9-1945 |

| Electric

Flashlights - Navy |

$103,000 |

6-1945 |

9-1945 |

| Total |

$8,109,000 |

|

|

Delta Electric supplied two each of part

number DL-A-74s headlight plugs for only early World War Two era half-tracks like this M2A1. The later models that did

not use the Delta Electric plug had the blackout light attached to the

top of the headlight. Of the 40,003 half-tracks built by Autocar,

Diamond T, and the White Motor Company, about half of the surviving

examples didn't have the blackout light attached. Therefore, Delta

Electric would have supplied approximately 40,000 headlight plugs. Author's

photo added 9-20-2020.

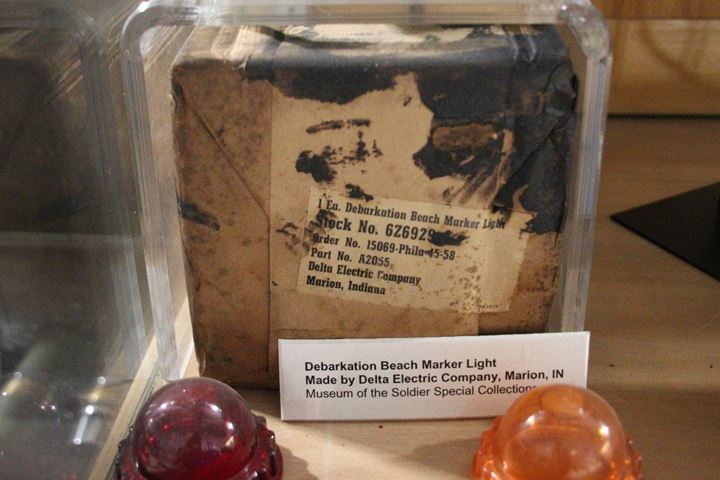

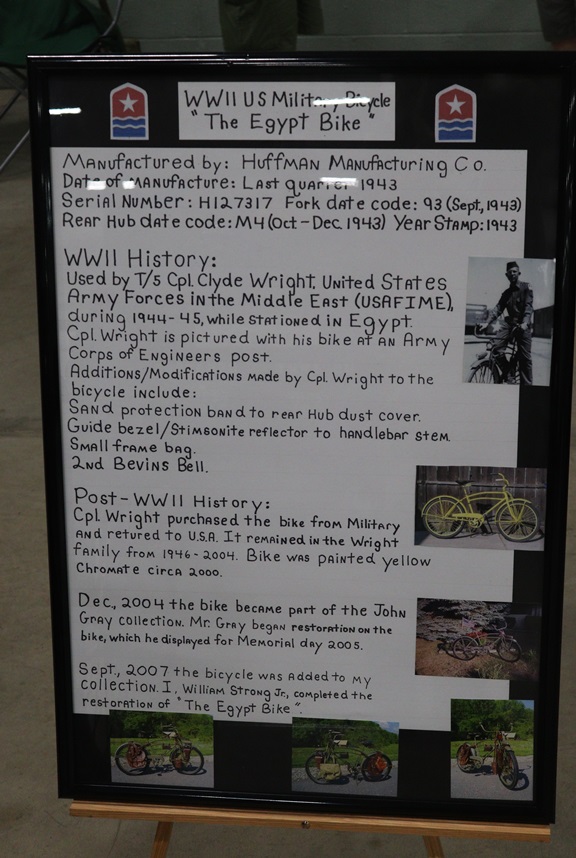

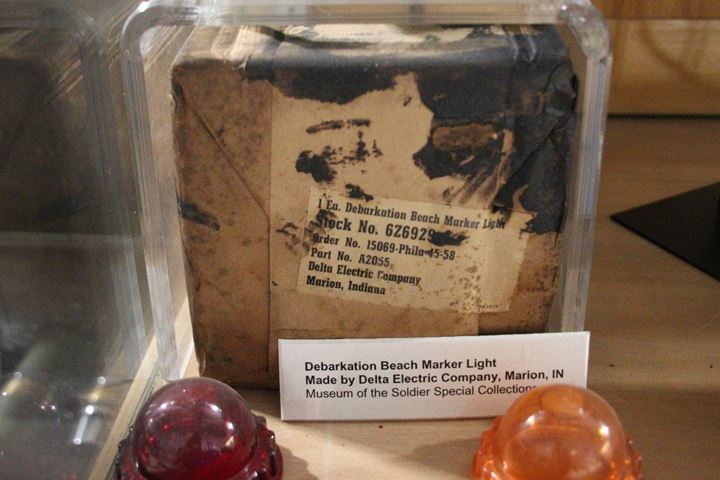

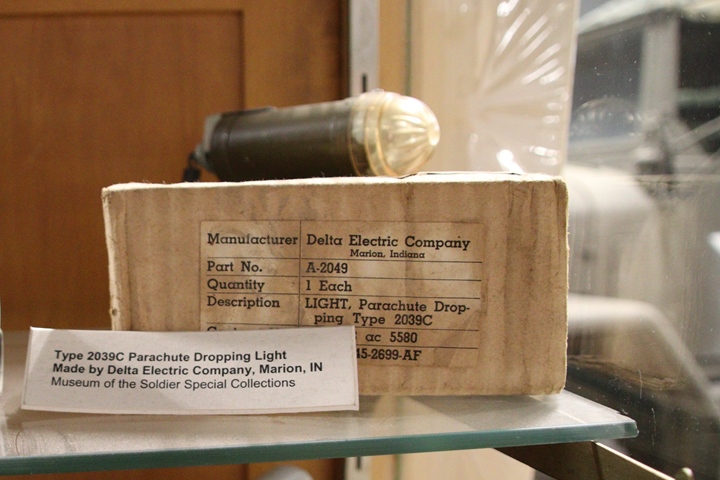

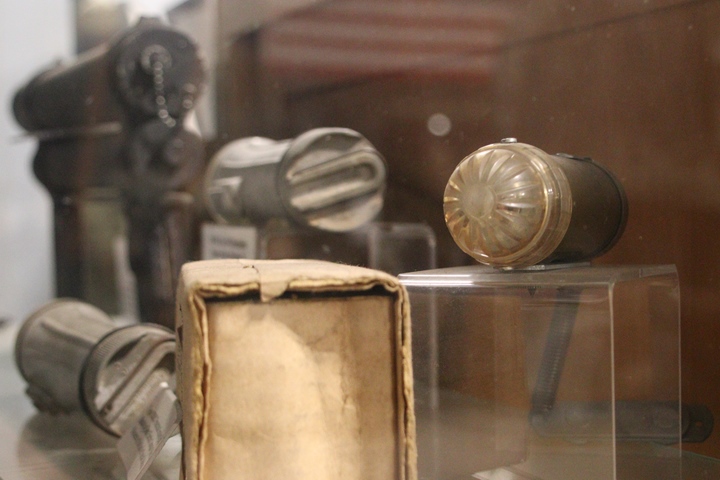

This display of Delta Electric Company

military products is located at the Museum of the Soldier in Portland,

IN. This is a very cool military museum that contains a large

variety of displays and historical artifacts. One of the museum's

specialties is the collection and display of products made by Indiana

companies for the U.S. military, with emphasis on World War Two.

Many of the photos on this

page are from the display at the Museum of the Soldier. Photos of

Delta Electric Company products from other museums are also included. All photos are by the author.

There are six different product types in the

display at the museum.

This is a Debarkation Beach Marker light for

the U.S. Army. From the description of the item, several of these

would be set up on the landing beach by the first soldiers ashore for

incoming landing craft to

designate where each landing area was located. There are four different colored lenses which could define

whether it was red, blue, green, or yellow beach. I was unaware

there was such a light for this purpose and have learned something by

visiting the Museum of the Soldier.

This product was ordered by the Army, as

the Order No. has "Phila" in it. This was ordered by the U.S. Army

Quartermaster Depot in Philadelphia, PA.

This side view shows the metal stand that

would be set down in the sand on the beach. There is a lever at the top

which is the ON switch for the battery-powered light. This

is a unique product and display.

This is another unique Delta Electric

Company product on display at the museum. The binoculars were not

made by Delta, but the battery-powered signal light in the middle was.

The knob at the top is a rheostat for adjusting the intensity of the

light, while the small button at the top would turn the light beam on and off. The beam was low power, to focus for signaling

short distances. This was a portable unit that may have been used

by Navy beach masters to communicate with incoming

landing craft from invasion beaches.

This angle shows the power cable to the battery

container, which looks like it would contain four D-cell type batteries.

The battery power supply allowed the unit to be operated where

there was no power, such as a landing beach.

For a sailor who went overboard off of a ship

or boat in the night, this Delta Survival Signal Light could make all

the difference as to whether he was rescued. Once in the water,

the sailor would turn the lens to activate the light to give his

location in the water. The light was powered by one D-cell

battery. As can be seen, the unit clipped to the sailor's shirt or

life jacket.

As is noted below the display, this is a

U.S. Army Signal Gun powered by five D-cell batteries in the lower tube.

The construction is of plastic and vulcanized fiber tubing. This

suggests it was used in training, as it is not robust enough for combat.

This is just another interesting and unique item at the

Museum of the Soldier.

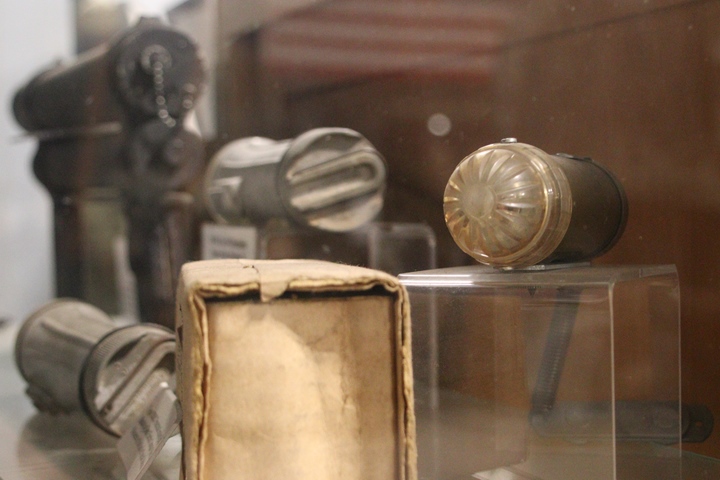

The display contains two Navy flashlights.

The cases and end caps look to be made of aluminum die cast, making

them robust units. Rubber gaskets make the flashlights waterproof.

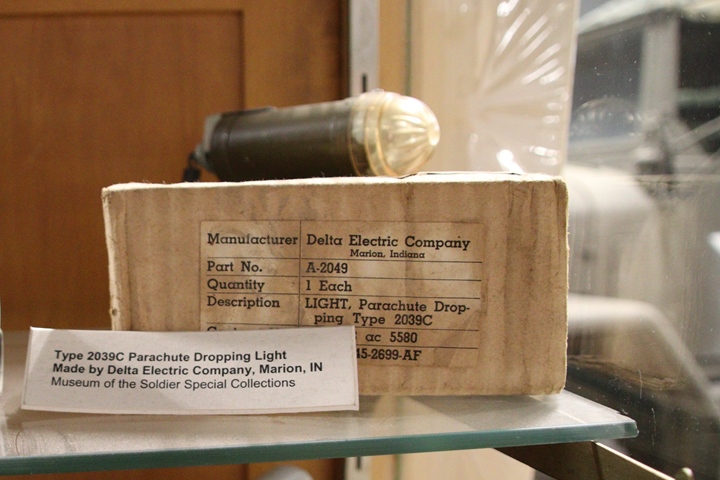

This light was built for the U.S. Army. Such

lights were

attached to supplies parachuted to troops on the ground, so the items

could be located in the dark.

This photo shows the top of the

Parachute Dropping Light plus the end caps of the Navy flashlights.

The end caps have extendable hooks that can be attached to a sailor's

belt.

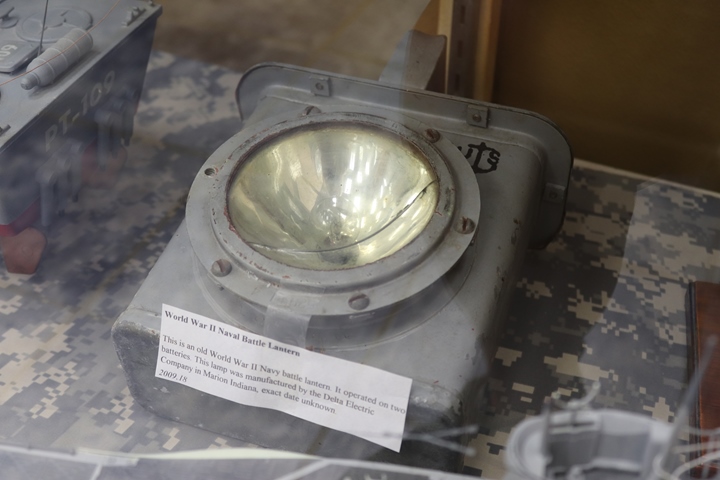

This is a World War Two ear battle lantern that

was attached to the bulkheads of Navy ships for use if the power went out

during combat. The small lever on the front of the lantern would

turn on the unit and light up the immediate area.

It could also be removed from the bulkhead for personal use. The batteries for

all of these units would need to be checked on a regular basis, to make

sure they still had a charge, and had not corroded.

This photo shows the back of the lantern

with its mounting button. It also shows how to load or remove the

batteries, requiring six or eight screws to be removed, depending on the

model type. These are heavy duty units

constructed of painted steel.

As noted above, this unique display is located

at the Museum of the Soldier in Portland, IN. For the military

historian or enthusiast, this is a really cool museum located in east

central Indiana. The museum has limited hours during the

summer months, so some advance planning is needed to visit. It

will be worth it.

The following four photos of a World War Two

Delta Electric U.S. Navy lantern are from the John Stanton collection.

The lantern is unusual as it is made of brass. The others shown on

this page appear to be made of painted steel. Several of

the painted examples are showing signs of rust indicating they are of

steel construction.

This photo shows that the lantern was powered by two dry cell batteries.

Photo courtesy of John Stanton added 10-27-2022.

Photo courtesy of John Stanton added

10-27-2022.

This photo shows how several pieces were

soldered together to make the lantern. Photo courtesy of John

Stanton added 10-27-2022.

The top of the lantern lid indicates that this is

a type K-10A lantern. Photo courtesy of John Stanton added

10-27-2022.

Below are more Delta Electric World War Two

products on display at

other military museums.

This is one of two Delta Electric Company

U.S. Navy lanterns on display at the Central Ohio Military Museum

in Harrisburg, OH. This museum opened in 2018. Note that this model of

the lantern has a toggle switch to turn it on.

The museum has the lantern mounted to the

wall, similar to how it would be mounted on the bulkhead of a ship.

The lantern could either be turned on to provide emergency lighting in

the compartment it was in or be taken off the bulkhead for use by a

sailor.

Bob Traphagan, the curator of the Central

Ohio Military Museum, was most helpful in moving around various

items in the museum that I wanted to photograph.

Here is the backside of the lantern, showing the mounting bracket with

the Delta Electric name and address stamped into it.

Special thanks go out to Mr. Bob Traphagen, the

curator of the Central Ohio Military Museum. Bob went above and beyond

the call of duty to assist the author in showcasing the historic

artifacts of this museum. There were several items that needed to be

moved or handled, and he assisted me with that. Included in that

group were the lanterns, the flashlight, and a Galvin Handie-Talkie.

The other Delta lantern is next to a photo

of curator Bob Traphagan when he was in the Navy. Next to him in

the photo is his father, who also was a Navy veteran.

The museum also has a U.S. Navy flashlight on display. Note the

wire loop on the end that allowed a sailor to attach the flashlight to

his belt.

This was my first visit to the Central Ohio Military Museum. I

plan to return to this excellent museum just south of Columbus,

OH.

This Delta Electric Lantern was photographed

at the Museum of Military History in Kissimmee, FL.

The Museum of Military History in

Kissimmee, FL is another of those small military museums gems, like the

two previously mentioned. The museum is not too far from the

main entrance to Disney World.

This Delta Electric Lantern was photographed

at the Fighting Falcon Military Museum in Greenville, MI. Author's

photo added 4-25-2021.

Another Delta Electric lantern is on display at the Michigan

Military Technical and Historical Society in Eastpointe, MI.

Author's photo added 4-25-2021.

This Portable Type A Signaling Light is on

display with its carrying case at the LST-325 Museum in Evansville, IN.

Author's photo added 4-29-2022.

Author's photo added 4-29-2022.

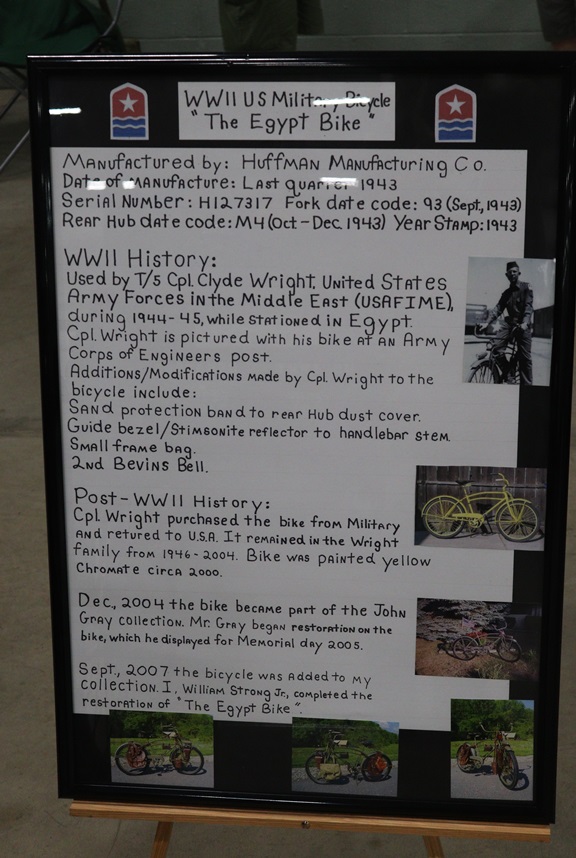

Delta Electric supplied the headlights for

the 70,945 bicycles produced for the U.S. military during World War Two.

This one is on one of the 19,750 bicycles built by the Huffman

Manufacturing Company (later known as Huffy). Author's photo added 3-2-2022.

Author's photo added 3-2-2022.

This Huffman-built bicycle with a

Delta-built headlight served with the U.S. Army in Egypt. Author's

photo added 3-2-2022.

Author's photo added 3-2-2022.

Delta supplied 51,195 headlights for the

military bicycles built by Westfield Manufacturing Company.

Author's photo added 3-2-2022.

Author's photo added 3-2-2022.

|