|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Fisher Body Plant 21 - Detroit Aircraft Unit in World War Two

A Surviving Fisher

Body Plant

Detroit, MI

1919-Current

Fisher Body - Gone but not Forgotten!!!

This page added 2-25-2021.

This imposing six-story building was the former Fisher Body Plant 21, located at the corner

of Piquette and St. Antione Streets in Detroit, MI. During

World War Two, it was the Detroit Aircraft Unit.

It was built in 1919 by Albert Kahn for the Fisher Brothers, seven years

before they became part of General Motors. The plant closed in

1984. General Motors was apparently was able to sell the building

and then the new owners either moved out later or were not able to

maintain such a large building. Even though one million dollars have been spent on cleaning up the legacy

environmental contamination inside the plant, it is still on the EPA

contaminated list.

From an architectural standpoint, this plant is

an excellent example of the multi-story auto plants that dotted the

Detroit landscape in the early 20th century. Fisher Body Plant 21

is one of the most photographed buildings in Detroit, due to its

symbolism in representing what the American Automobile Industry was when

it dominated the world, contributing mightily to winning World War Two, and then its

fall from dominance when it focused on the short term bottom line

instead of taking care of its customers. Author's Photo.

The Fisher Body Detroit Aircraft Unit won the Army-Navy "E" award

four times.

Fisher Body Detroit Aircraft Unit World War Two Products:

B-25, B-29, XP-75, P-80, and FG-4 aircraft parts and assemblies

B-29: The table below shows

that the proposed shipment schedule did not match up with the number of

B-29s built in each plant. Renton was scheduled to receive almost

three times the number of tail gun and rudder assemblies compared to the

number of the B-29s built. It is unknown from the historical

record whether the excess components were shipped to the other plants.

The Fisher Body Detroit Aircraft Unit made more than enough of the

assemblies to supply all of the B-29s built.

| Fisher Body

Detroit Aircraft Unit B-29 Components Shipment Schedule |

| |

Boeing-Renton, WA |

Boeing-Wichita, KS |

Bell-Marietta, GA |

Martin, NE |

Total |

|

Number of B-29s built |

998 |

1,595 |

652 |

515 |

3,760 |

| Tail gun assemblies |

2,700 |

601 |

200 |

400 |

3,901 |

| Rudder pedal assemblies |

2,700 |

|

900 |

750 |

4,350 |

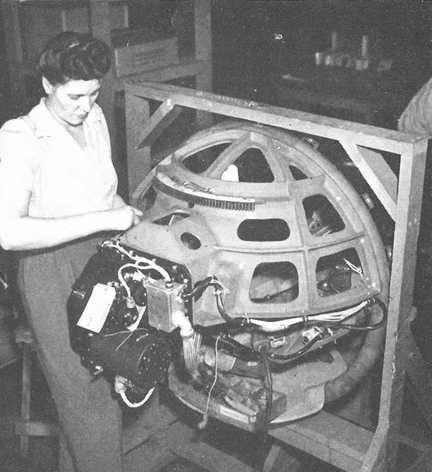

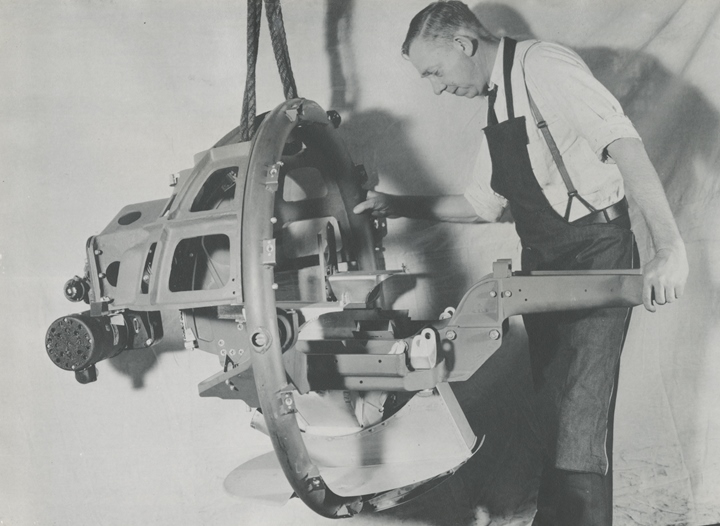

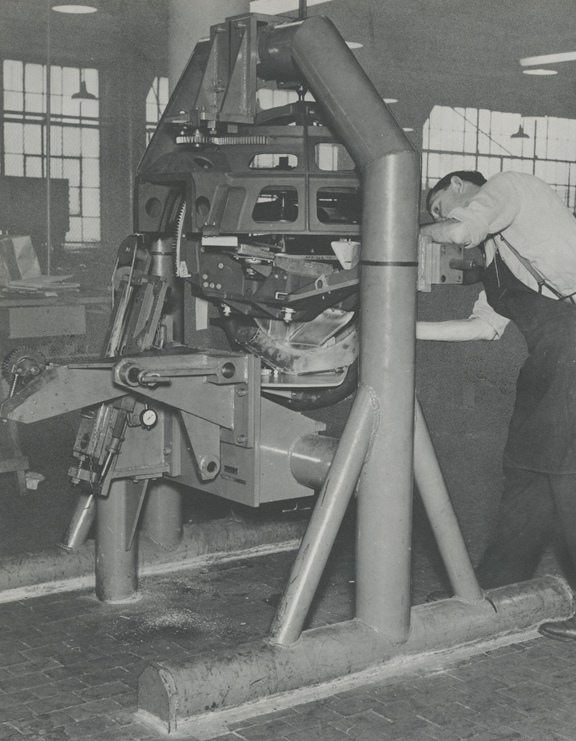

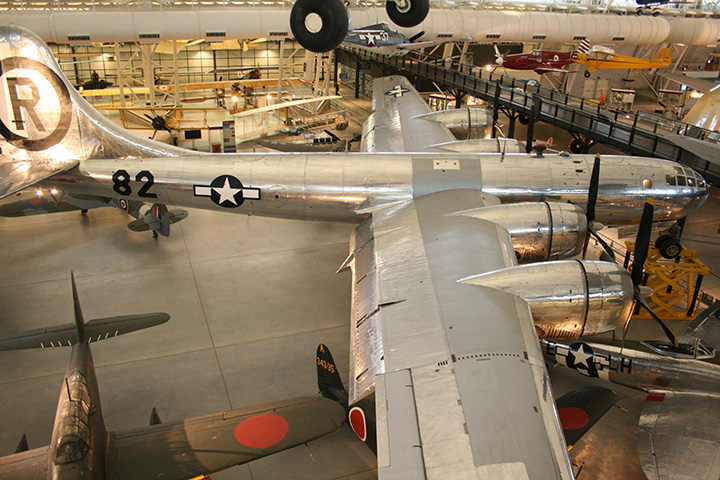

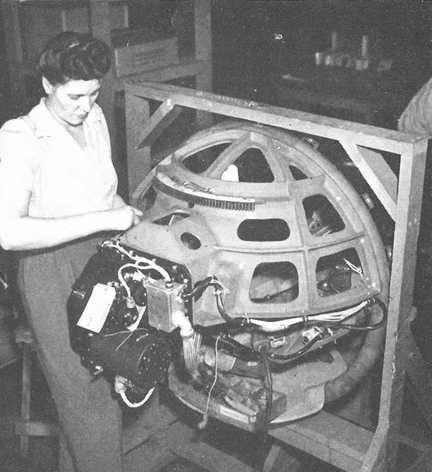

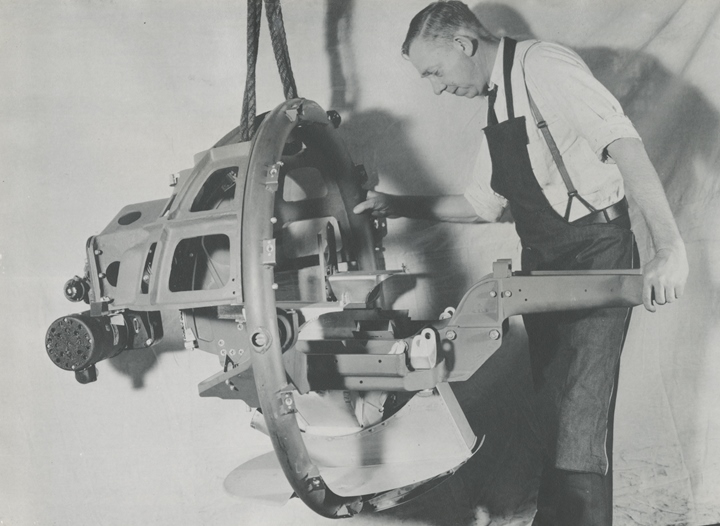

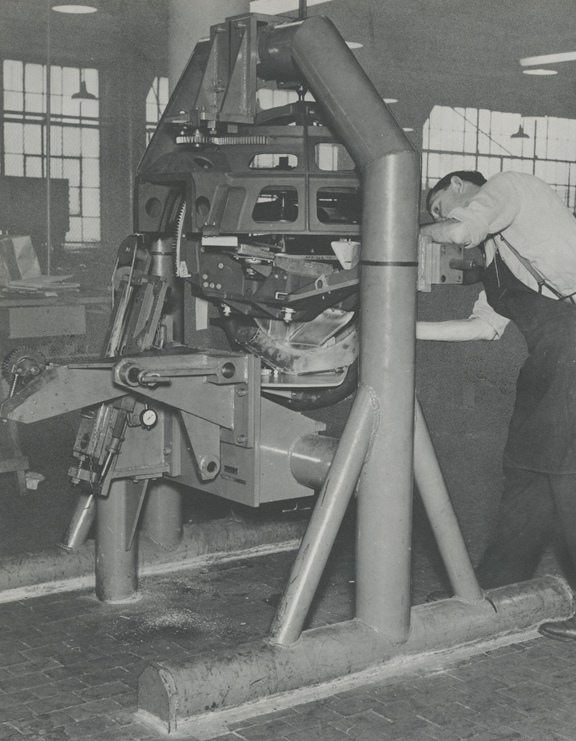

The next three photos show the B-29 tail

gun assemblies being assembled at the Detroit Aviation Unit.

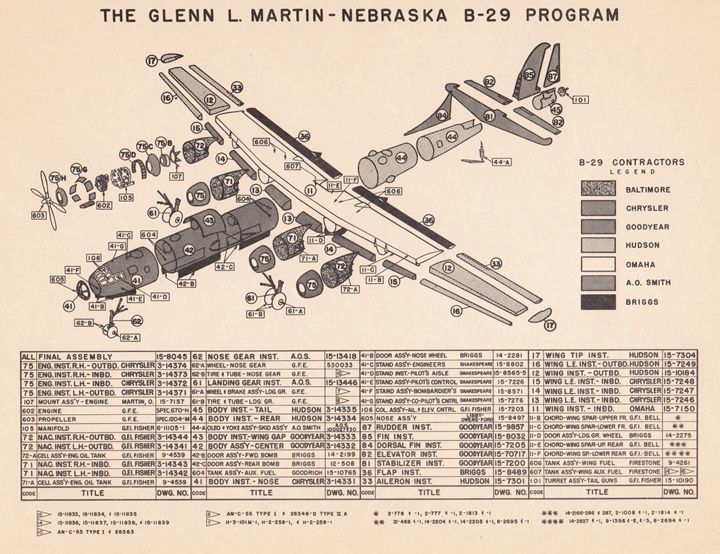

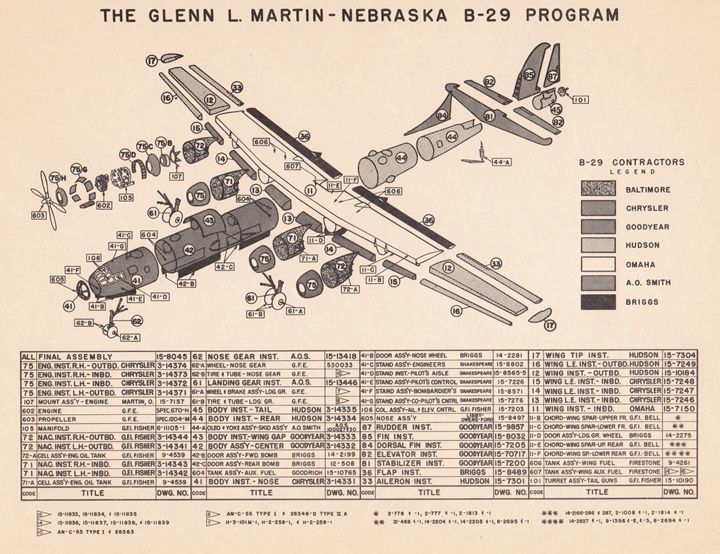

This shows the main contractors for the

B-29s built by Martin Omaha, NE. Part number 101, in the lower right

hand corner of the table, shows that the Turret Assembly-Tail Guns were

furnished by G.F.I Fisher. G.F.I. stands for Government Furnished

Items. The Army Air Force contracted directly with Fisher Body to

purchase the tail gun assemblies, and then had Fisher Body drop ship

them to the B-29 assembly plants per its instructions.

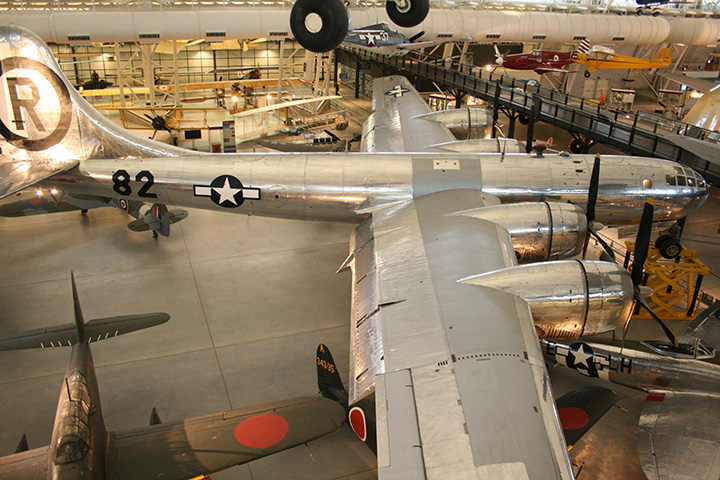

The B-29 Enola Gay was built at the Martin

plant in Omaha, Nebraska. Fisher-Body was shown as the supplier of the

tail gun turret assemblies.

Author's photo.

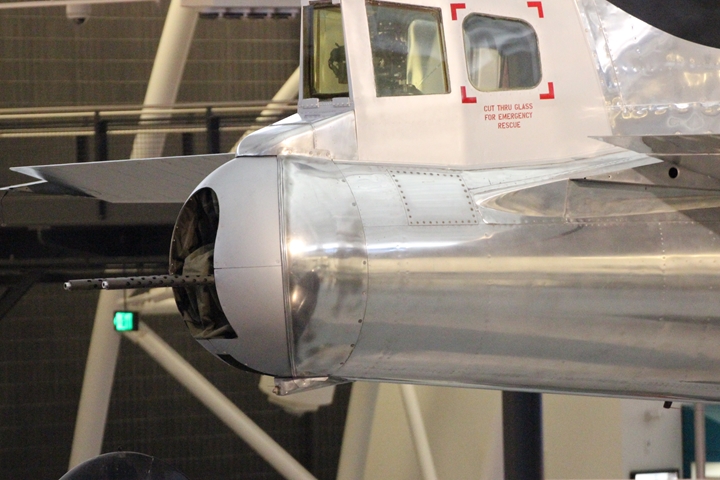

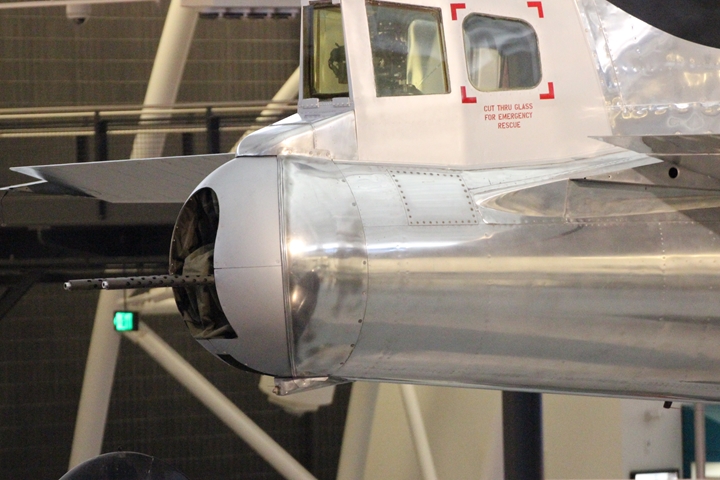

The next several photos show the Fisher

Body-built rear gun turret in the Enola Gay. All of the other gun

turrets were removed from the aircraft to decrease the weight of the

aircraft. The tail gun turret was considered important enough to

prevent an attack from behind, so it was left in the aircraft.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

XP-75 and P-75A:

The Fisher Body Detroit Aircraft Unit

fabricated and assembled rudder pedals for the aircraft. It also

assembled fairings and cowlings fabricated at other Fisher Body plants.

Only (8) XP-75s and (6) P-75s were built during World War Two. While

only fourteen total airframes were built, Lansing and other Fisher Body

plants were planning and producing for a high production run. Many more

than fourteen sets of components were built. This

is the only remaining P-75A Eagle of the fourteen aircraft that were

built. It is on display at the National Museum of the

United States Air Force.

Author's photo.

Author's photo.

What didn't happen: In the "Fisher

Body Craftsmanship goes to War" it notes that there was a

contract placed for Lockheed P-80 intakes and wingtips. There was

also a contract to build 1,500 FG-4 engine cowlings for Goodyear.

Both contracts were issued late in World War Two and neither was

completed. Very few parts, if any, were built or delivered due to

the sudden end of World War Two in August 1945.

Several historical sources

have misinterpreted this information and claim the Fisher Body Detroit

Aircraft Unit actually built P-80s and FG-4 complete aircraft. The contract

was for tooling and parts, not entire aircraft.

The FG-4

was to be the Goodyear-built version of the Vought F4U-4 Corsair.

It never went into production due to the sudden end of the war in August

1945. This is a Vought F4U-4 that was built after World War Two.

The Detroit Aircraft Unit would have built the engine cowl like the one

on this aircraft. Author's photo.

This is a Lockheed P-80. The Detroit

Aircraft Unit never had the opportunity to make parts for this type

aircraft due to the end of the war. Author's

photo.

The Detroit Aircraft Unit was contracted to

build tooling and to make the wingtips on the P-80. Author's

photo.

The Detroit Aircraft Unit was also going to

make tooling and build P-80 engine intakes. Author's photo.

|