|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant

Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Surviving Fisher Body Plants - General Motors Corporation in World War

Two

Detroit Die and

Machine Plant (Fisher Body Plant #23)

1920-19??

This page updated

2-12-2022.

The Fisher Body Die and Machine plant on

Piquette Avenue covered an entire city block between Beaubien and

Hastings Streets in the Milwaukee Junction area of Detroit. Parts

of the plant still exist today.

Fisher Body Die and Machine Plant

World War Two Production

Statistics: B-25, B-29, P-80 aircraft tools and fixtures; M4,

M10, M36, M26, M18 tank parts; three-inch and five-inch Naval

Gun Breech Housings, 155mm and eight-inch gun parts, Diesel Engine parts and Torqmatic Transmission parts.

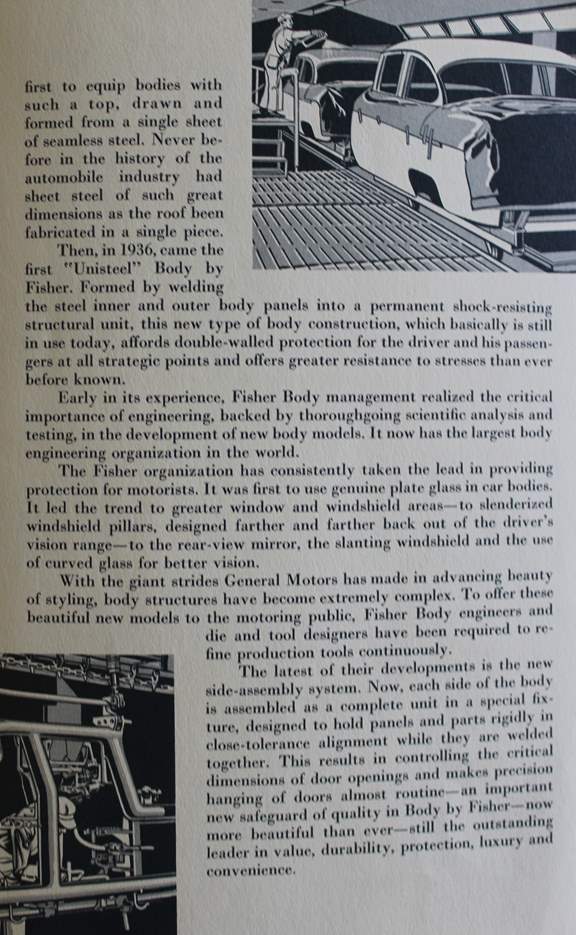

The Tool and Die plant in the 1950s'. The building in the photo below is in the upper left and is the

southwest corner.

This is the former Fisher Body Detroit Die

and Machine Plant at the corner of Piquette Avenue and Beaubien Street

in Detroit, MI. It is still in use as a stamping plant under a new owner.

Author's Photo.

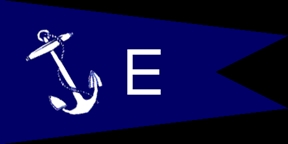

The Die and Machine Plant was the first auto company to receive the Navy

"E" for Excellence award. It would add six stars and keep its original Navy "E" Award

instead of converting it to the new Army-Navy "E" for Excellence award.

The original award (flag) was received in November 1941 for being

"ahead of schedule production" of five inch naval gun breeches.

The first star came six months later for "steady production"

five inch

naval gun breeches of in May 1942.

The second star was added for "uninterrupted production" five inch naval gun

breeches on November 10, 1942.

Four more stars were added at later dates during the war.

Only 4,283 plants out of 86,000 were awarded

either a Navy or Army-Navy "E" for Excellence awards during the war.

The Fisher Body Die and Machine plant was one of only eight plants to be

awarded six stars, the most ever given.

The Navy "E" flag with six stars.

Naval Five-Inch Gun Breech Housings for the

US Navy: The order to Fisher Body was originally made in

September 1940, and called for a production rate of 25 units per month.

In April 1941 the first shipment was made. From that point on, the Die

and Machine plant was always ahead of the Navy schedule, hence the

record number of Navy awards. In July 1943, 170 breech

housings per month were coming off the assembly line. A total of 6,342 housings were shipped during the conflict, with Fisher

Body Grand Rapids starting production in March 1944.

Naval skeptics did not believe that the

Die and Machine Plant could produce 25 units per month when its own

Naval Gun Factory could only turn out five per month. It seemed impossible

to the skeptics that Fisher Body could machine down an original 6,100

pound rough forging to a finished weight of 2,932 pounds, to which 217

other components had to be added. But the mass production

expertise of Fisher Body made it all possible.

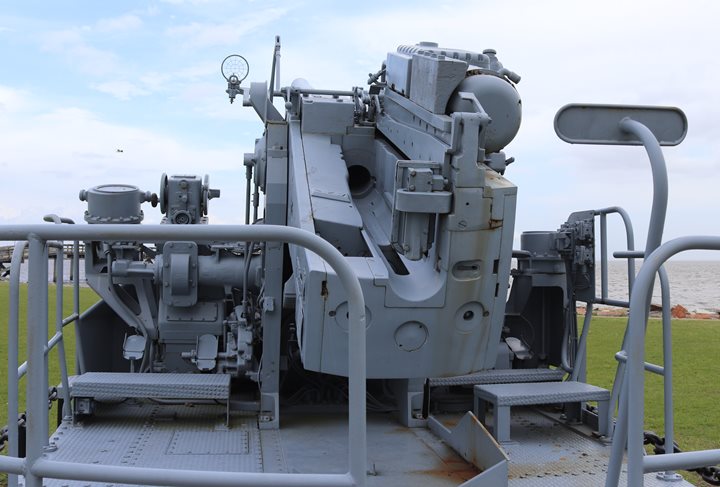

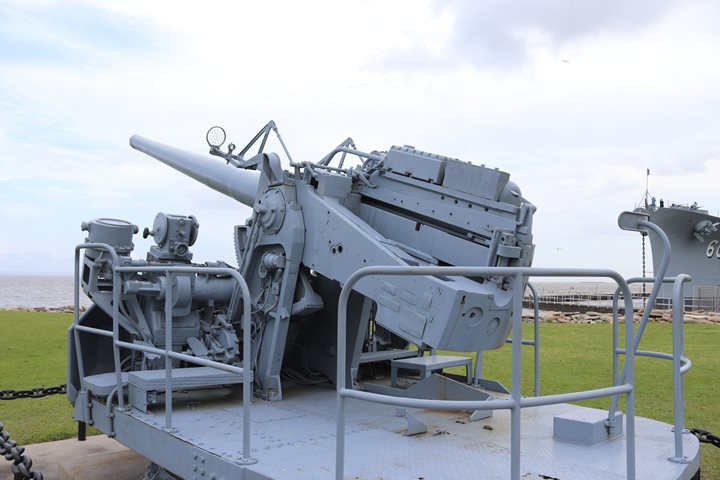

The main armament on US Navy destroyers

during WWII was the five inch, 38 caliber gun, for which the Die and

Machine plant supplied the majority of 6,342 breech housings made by

Fisher Body. The USS Kidd

on display in Baton Rouge, LA is armed with four 5 inch main guns.

Author's photo.

This five-inch, 38 caliber gun can be

seen at the USS Sullivans at the Buffalo and Erie County Naval and

Military Park in Buffalo, NY. Author's photo added 11-10-2017.

The five-inch 38 caliber naval gun was also

used on cruisers, battleships, and aircraft carriers. It could

either be used against other ships, for land bombardment, or for

anti-aircraft defense. It was the most versatile weapon used by

the US Navy during World War Two.

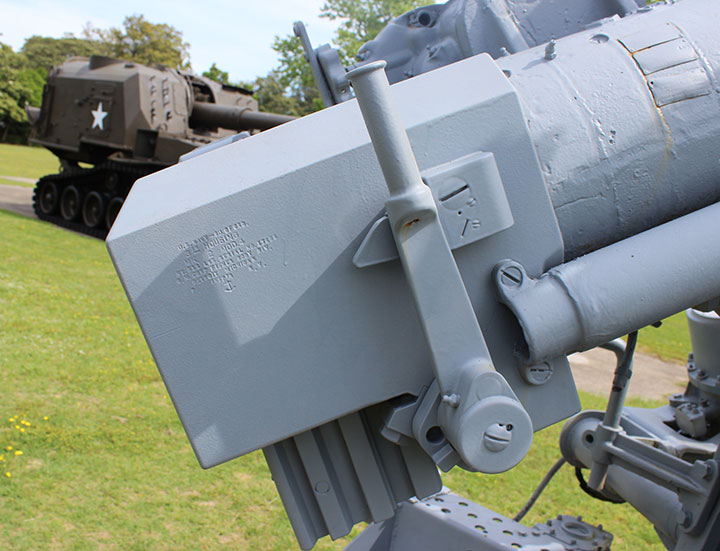

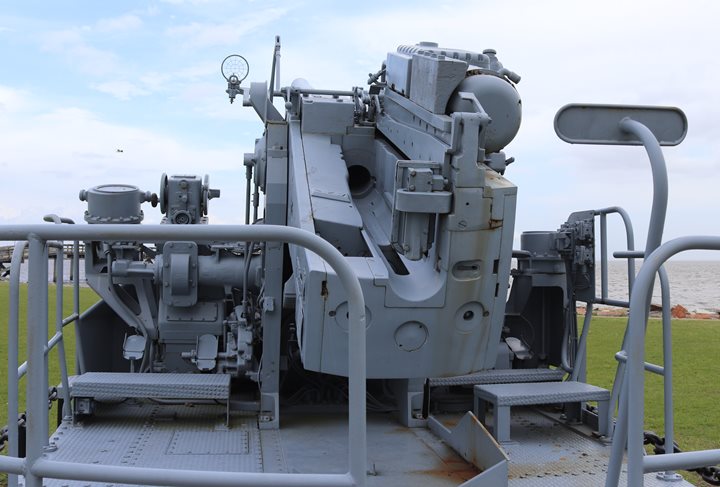

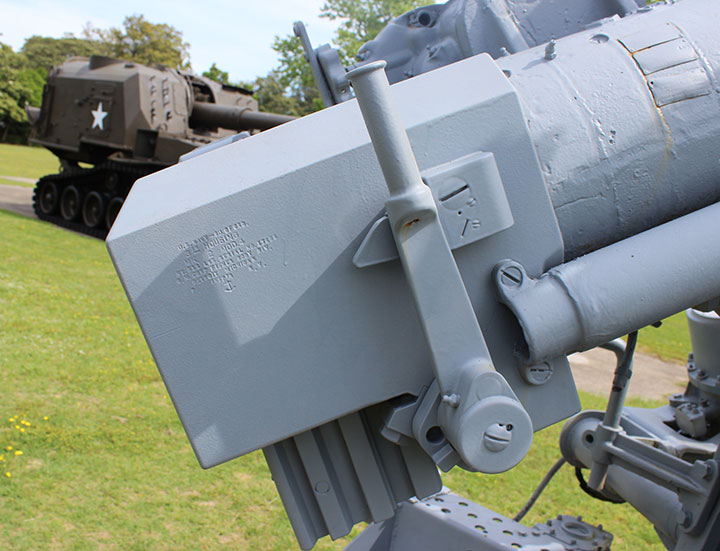

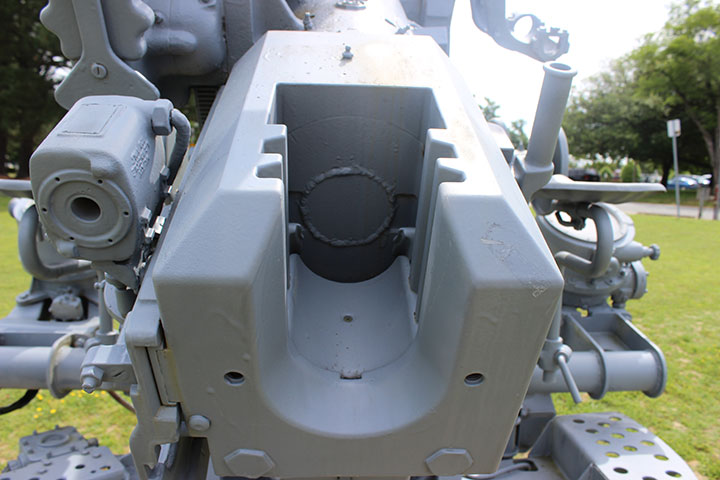

This is one of four five-inch, 38 caliber

guns on display at the USS Alabama in Mobile, AL. These do not

have the armored turret on them that were used on combat ships

for self protection. This allows for an excellent inspection of

the weapon. Author's photo added May 14, 2018.

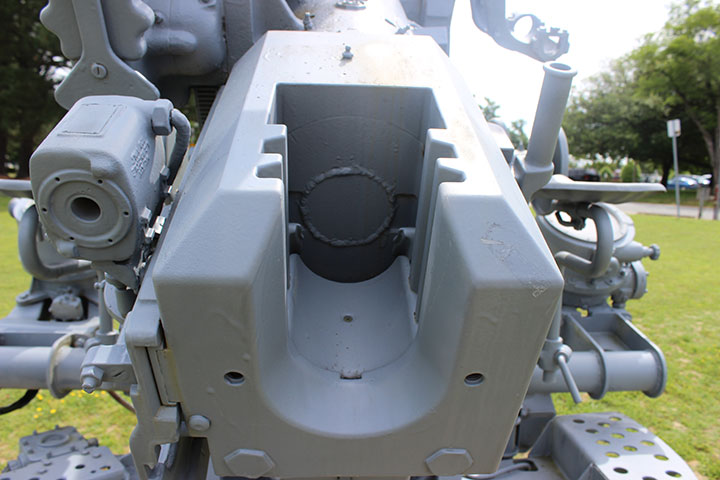

The gun mechanism was a complicated and

precision device consisting of 218 components. The Fisher Body

built breech housing weighed 2,932 pounds and is component in the center

of the gun mechanism with the opening for the five-inch round to which

the remaining 217 components were added. Author's photo added May

14, 2018.

Author's photo added May 14, 2018.

Author's photo added May 14, 2018.

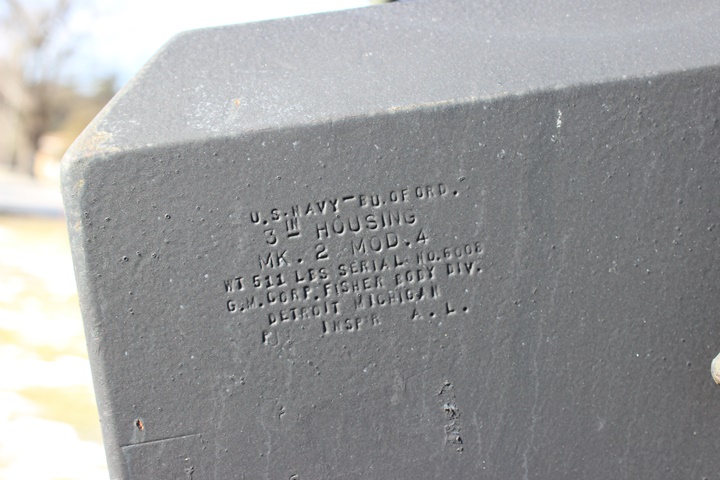

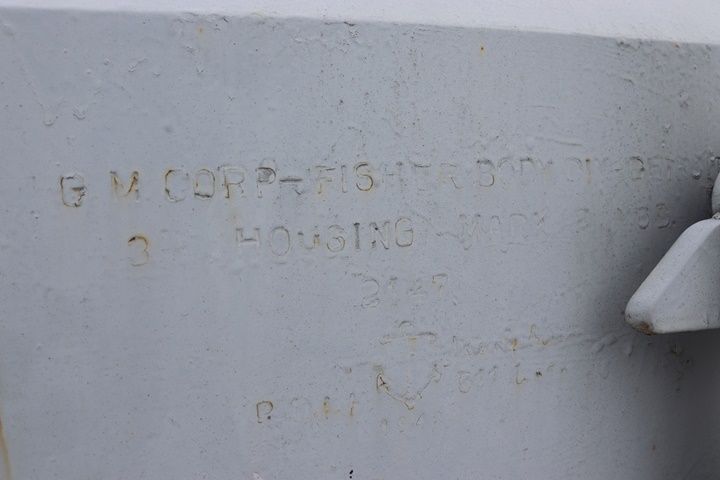

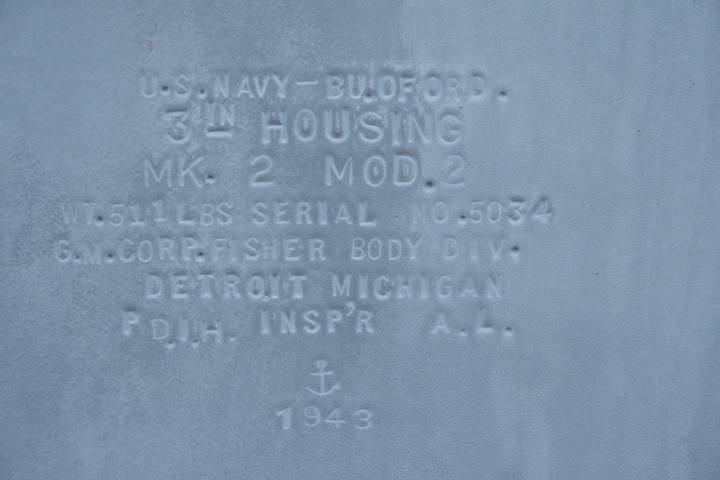

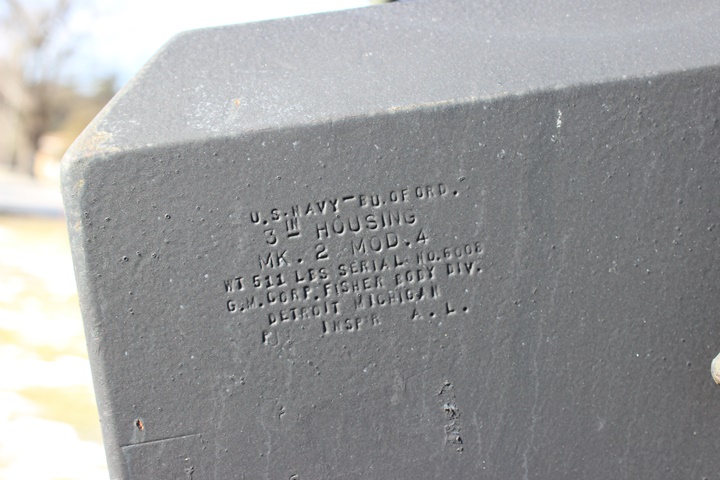

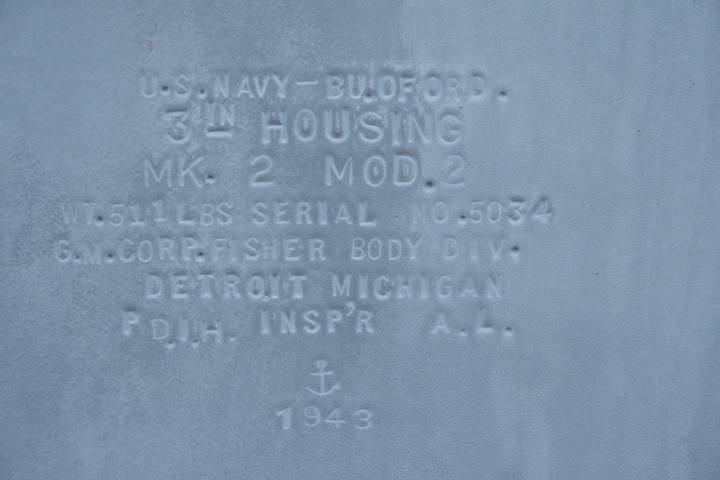

Naval Three-Inch Gun Breech Housings for

the US Navy: The Die and Machine Plant also produced 9,459

three-inch naval breech housings starting in April of 1942, at a rate of

100 per month. This run rate was achieved four months ahead of

schedule and one month before the first one was contracted to be shipped!

The three-inch guns were used on 2,710 Liberty ships, 534 Victory ships,

1,050 LSTs, 97 Evarts Class Destroyer Escorts, 105 Buckley Class

Destroyer Escorts, and 72 Cannon Class Destroyer Escorts. The three-inch gun was also used on

various types of merchant shipping during the war.

The Mark 2 three-inch/50 caliber gun was

served by a seven man crew, and had a muzzle velocity of 2,100 feet per

second. It had a maximum range of 14,000 yards against surface

targets and could reach 30,000 feet when used against aircraft. With a well

trained crew, it could fire 18 rounds per minute.

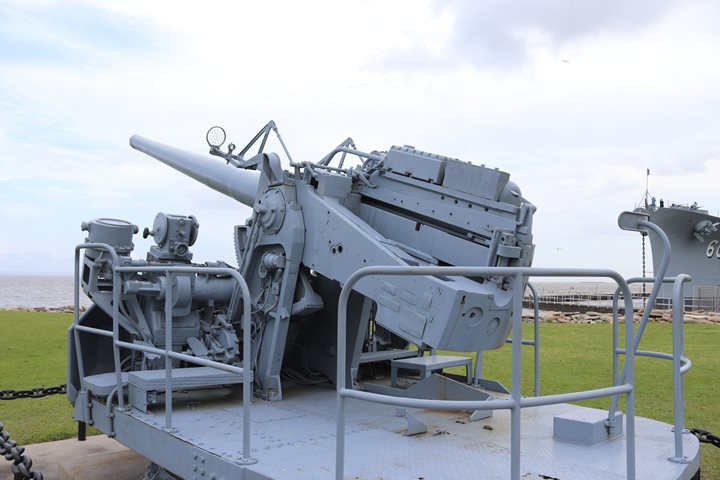

The USS Slater DE-766: I was able

to visit the USS Slater in August of 2017. This is the best ship's

tour I have been on! The guided tour of the top side of the ship

was most informative. Beside finding the Fisher Body three-inch gun

breech, I was also found a GM Pontiac Division 20mm Orelikon on the

tour. I then paid for the engine room tour to view the seven GM

Cleveland Diesel engines onboard. Also found in the engine room

were two GM Harrison Radiator heat exchangers.

I highly recommend anyone interested in WWII,

or naval history to visit this excellently preserved ship. It is

the most complete of the WWII ships I have visited.

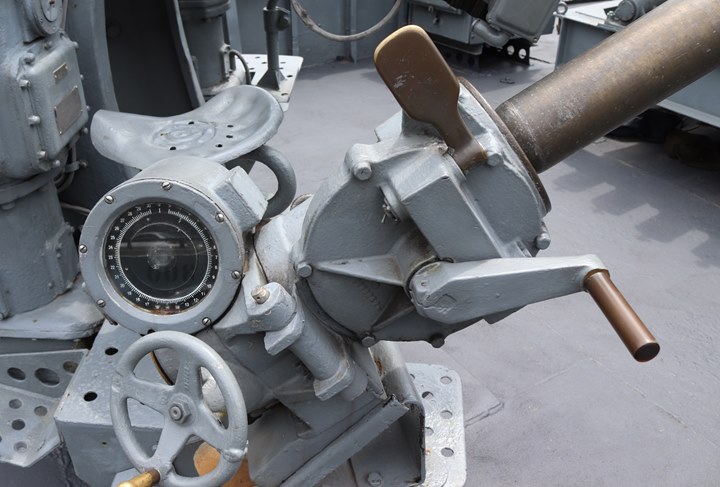

The Number 1 three-inch/50 on the USS Slater

DE-766 has a Fisher Body built breech. The USS Slater is on

display along the Hudson River water front in Albany. It is the

only Cannon Class Destroyer Escort on display in the world.

Author's photo added 8-25-2017.

Author's photo added 8-25-2017.

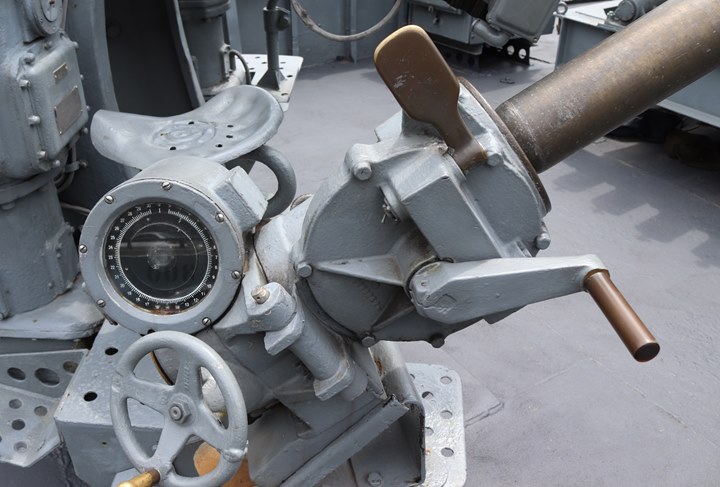

The tour guide encouraged those on the tour

to get on the gun mount and operate the elevation and transverse

controls. Author's photo added 8-25-2017.

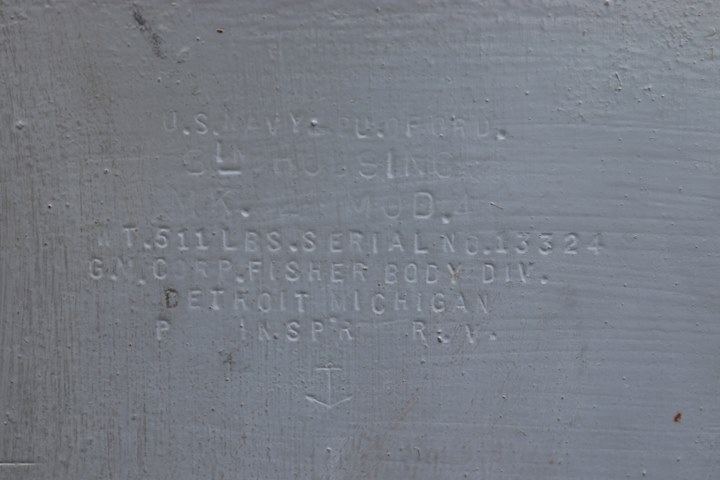

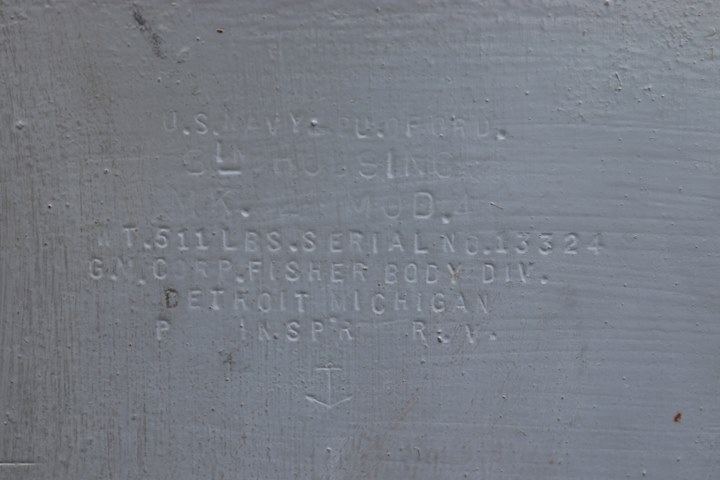

This is Fisher Body three-inch breech serial

number 13324. Author's photo added 8-25-2017.

The tour guide showed the size of the three-inch round to my tour group. Author's photo added 8-25-2017

Author's photo added 8-25-2017.

Author's photo added 8-25-2017.

This is one of the few three-inch guns I

have seen that has the range setting device on it. By inserting

the round into the device, the crew could then use the hand crank to set

the range for anti-aircraft fire. Author's photo added 8-25-2017.

Author's photo added 8-25-2017.

The ranger finder's scale runs from 0 to 30

which was 0 to 30,000 feet in altitude when the three-inch gun was used as

an anti-aircraft weapon. Its maximum range for a surface target

was 14,000 yards. Author's photo added 8-25-2017.

LST-393:

The LST-393 located at Muskegon, MI, is

one of only two LSTs (Landing Ship, Tank) on display in the United States. The LST is identifiable by its bow doors, which allowed it to

unload vehicles and troops directly to an invasion beach. A total

of 1,051 were built during WWII. LST-393 is 328 feet long and is

50 feet wide, and was designed to deliver tanks and other vehicles

directly to an invasion beachhead. Author's photo added 8-17-2016.

LST-393 was launched on November 11, 1942 in

Newport News, VA and saw service at Sicily, Salerno, and Omaha Beach in

Normandy. Sicily was the first utilization of the LST in combat.

LST-393 delivered 3,248 vehicles and over 9,000 soldiers during WWII.

Many of the vehicles and troops were landed during the 30 round trips

LST-393 made to Normandy. It also returned to England 10,000

wounded troops and 5,000 German POWs.

The LST was one of the most important weapons

in WWII. The Normandy Invasion was originally scheduled May 1, 1944. General Eisenhower delayed the operation one

month until June in order to obtain a few more LSTs for the landings.

Because the invading forces had no ports in Normandy to unload heavy

equipment and supplies, much of it would have to be unloaded out of the

open bow doors of LSTs on the beach. A total of 245 LSTs

were used at Normandy, still five short of the 250 originally planned.

But the invasion of Europe could wait no longer. Author's photo

added 8-17-2016.

On the port side gun position is a three-inch naval gun with a Detroit Tool and Machine Plant breech.

Author's photo added 8-17-2016.

In normal practice during WWII, the three-inch/50 caliber gun would be mounted on the fantail gun tub at the rear

of the LST. Since LST-393 was used as a car ferry on Lake Michigan

from 1946 until 1973, the ship was highly modified

from its original configuration, and currently does not have a fantail

gun tub. The current owner, the USS LST-393 Preservation

Association, took ownership of the LST in 2005 and has been working

diligently to restore the ship to original configuration. Author's

photo added 8-17-2016.

This is serial number 2174. Author's

photo added 8-17-2016.

Just a few miles away from LST-393 another three-inch naval gun

with a Fisher Body Detroit Die and Machine Plant made breech is on

display in front of the USS Silversides Museum. The submarine USS Silversides is visible in the

background. Author's photo added 8-17-2016.

This is serial number 1914. Author's

photo added 8-17-2016.

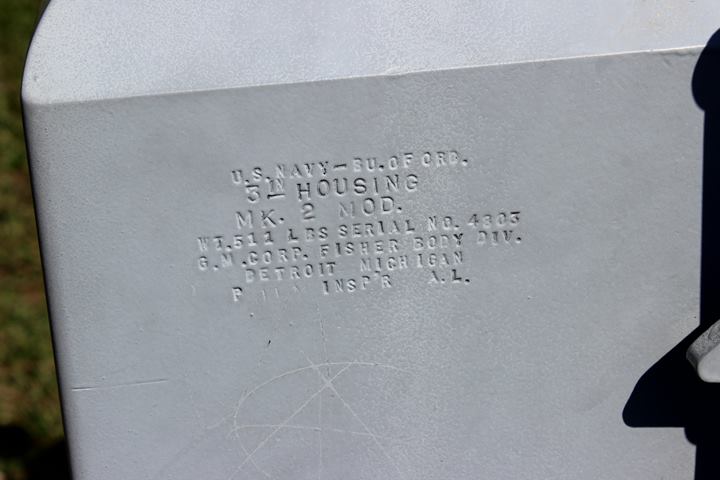

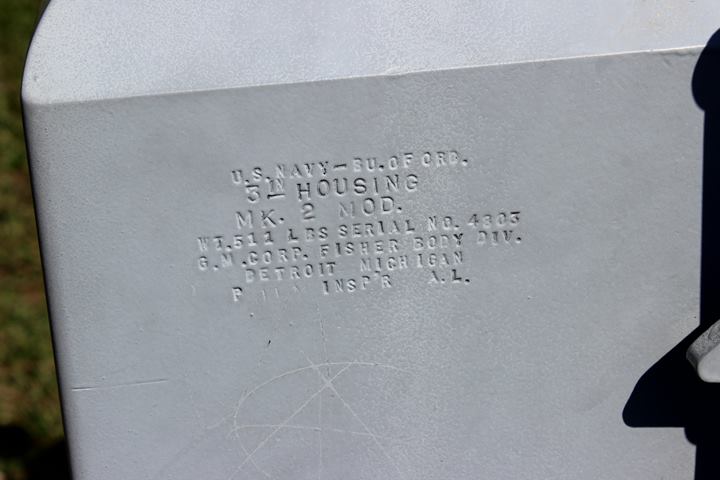

Guarding the entrance to the parking lot of

the Jeffersontown, KY Veterans Memorial Park are two three-inch naval

guns with Fisher Body Detroit Die and Machine Plant built breeches.

The weapon on the left, or west side of the entrance, is serial number

4803, and the one on the east side is serial number 2085 Author's

photo added 3-10-2017.

Serial number 4803. Author's photo

added 3-10-2017.

Serial number 4803. Author's photo

added 3-10-2017.

Serial number 2085. Author's photo

added 3-10-2017.

Serial number 2085 was manufactured in 1942.

Author's photo added 3-10-2017.

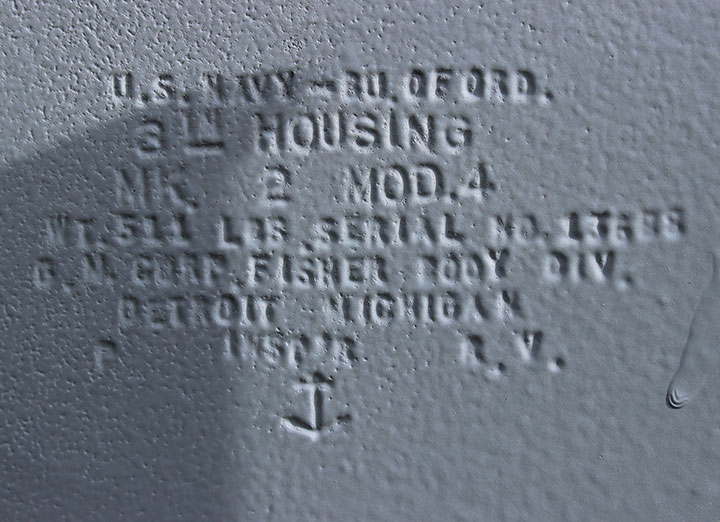

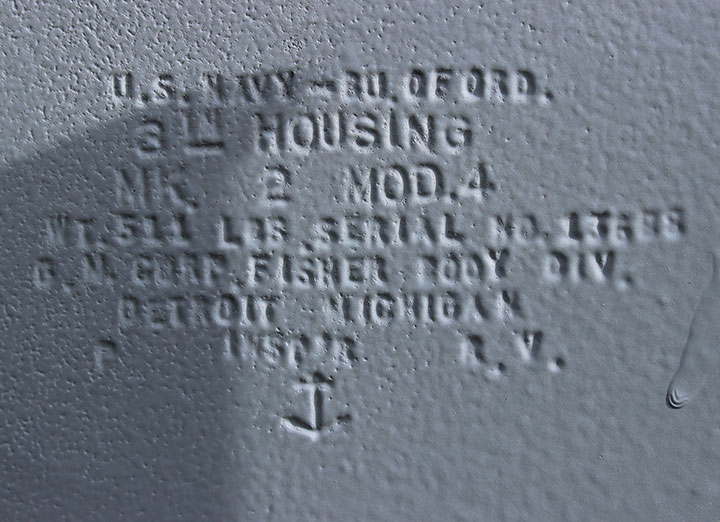

Shown here is a three-inch naval gun with a

Fisher Body Die and Machine Plant breech, as seen at the Virginia War

Museum. Author's photo.

This shows it weighs 511 lbs. and is serial number 13686. Author's

photo.

Author's photo.

Author's photo.

This particular three-inch Naval gun with a

Die and Machine Plant breech housing is on display at the Indiana

Military Museum in Vincennes, IN. Author's photo.

The serial number on the housing is 2728.

Author's photo.

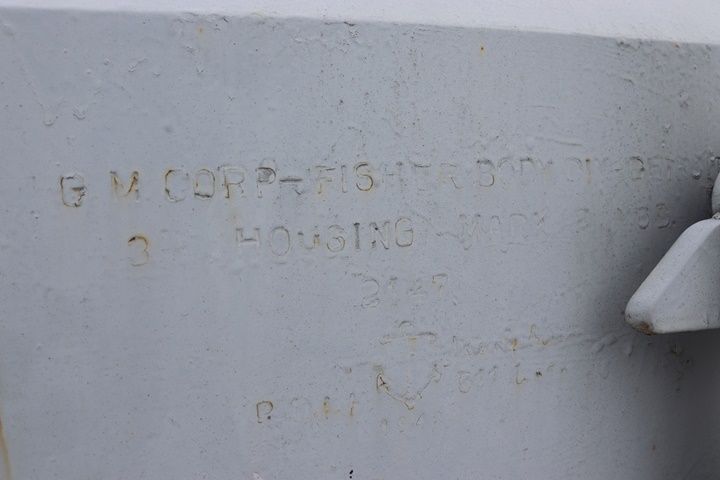

Two three inch-naval guns with Fisher Body

breech assemblies flank an M60 tank at the American Legion in Shelburn,

IN. Author's photo.

Author's photo.

This one is serial number 6008 and also

weighs 511 pounds. Author's photo.

Author's photo.

This is the weapon on the opposite side of

the M60 in the first photo. Author's photo.

Author's photo.

This three inch-gun produced by Fisher Body

Die and Machine is serial number 913, made in 1942.

Author's photo.

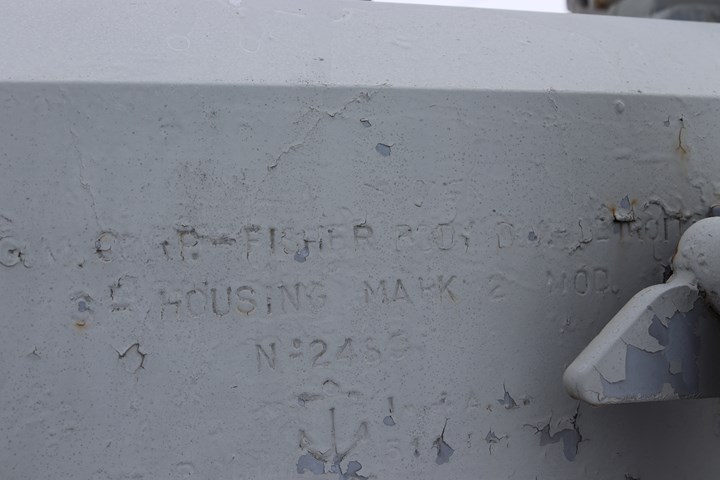

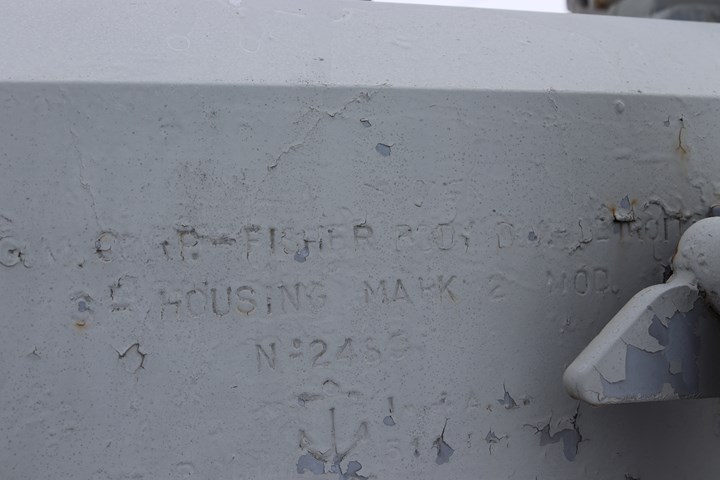

Two three-inch naval guns with Fisher Body breech assemblies are located

on the front lawn at the American Legion Post 479 in Lyons,

IN. Author's photo added 1-29-2018.

This three-inch gun produced by Fisher Body

Die and Machine is serial number 2489.

Author's photo added 1-29-2018.

Author's photo added 1-29-2018.

The second three-inch gun was produced by Fisher Body

Die and Machine and is serial number 2147, made in 1942.

Author's photo added 1-29-2018.

Author's photo added 1-29-2018.

This three-inch gun at the Brooke County

Veteran's Memorial Park in Weirton, WV has a Fisher Body breech assembly

serial number 5034. Author's photo added 2-12-2022.

Author's photo added 2-12-2022.

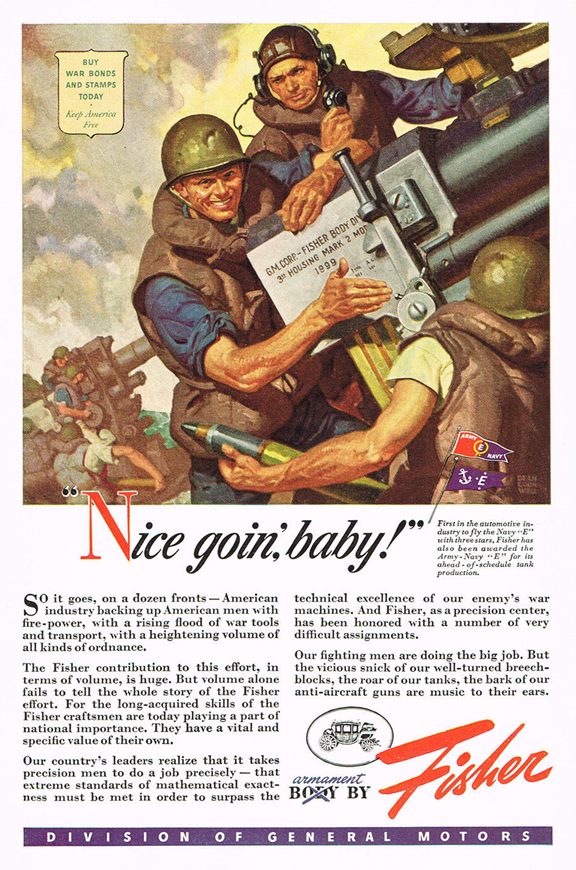

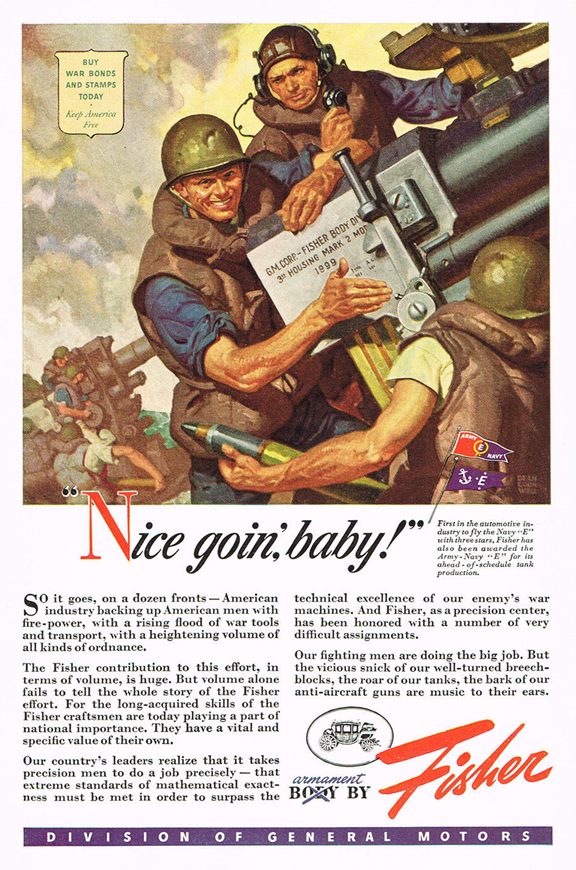

This ad shows the prominently marked Fisher

Body three-inch breech in action.

This ad shows the larger five-inch 38

caliber gun Fisher Body

breech housing.

The Fisher Body Die and Machine Plant was a

busy place during World War Two. Besides making nearly 15,000

naval gun breech housings, it made tooling for Army aircraft, parts

for tanks, diesel engines and Torqmatic transmissions.

Aircraft tooling and fixtures:

B-25, B-29, P-80

Tooling and fixtures for the North American

B-25 went to many Fisher Body plants, with Memphis being the main

producer of B-25 structural components for the division. Author's

photo.

Fisher Body supplied several components to

the Martin B-29 assembly plant in Omaha, NE. The most famous B-29

to come off the assembly line at Omaha was the "Enola Gay."

The Die and Machine plant supplied tooling and fixtures that made

components used in the "Enola Gay." Author's photo.

At the end of World War Two the US Air Force

was starting to tool up for the production of the new Lockheed P-80

Shooting Star. The Die and Machine Division of Fisher Body was

contracted to make tooling for the engine intakes and wing tips.

Some sources indicate Fisher Body built or was going to build the entire

aircraft. This is incorrect. In any event, the tooling was

not finished when the war ended. Author's

photo added 2-21-2018.

The wing tip on the P-80. Author's

photo added 2-21-2018.

The left air intake on the P-80. Author's

photo added 2-21-2018.

M4, M10, M36, M26, M18 tank and tank

destroyer parts: Fisher Body in Grand Blanc, MI had a tank

arsenal that built M4A2 and M4A3 Sherman tanks, the M10 and M36

Wolverine tank destroyers, and the M26 Pershing heavy tank. The

Die and Machine Plant in Detroit, MI supported this production with

parts for these vehicles along with the Buick assembled M18 Hellcat.

However, Grand Blanc was the main supplier of hulls and turrets for the

M18, and no doubt the Die and Machine plant supplied components for

their construction. Fisher Body supplied the majority of the

turret assemblies for the M36 Jackson. The Die and Machine plant

supplied components for the M36 turret which was assembled at the Grand

Blanc plant.

The Fisher Body Die and Machine Plant in

Detroit supplied parts for the type tanks and tank destroyer show below.

This M4A2(76)HVSS is Grand Blanc serial

number 69192 and registration number 30129671, built in April

1945. It can be seen outside the Beatty Street Drill Hall in

Vancouver, BC. It was one of 7,508 M4A2s built in the plant. Photo courtesy of David Jackson, Jr.

Of all of the Sherman tanks built during WWII, it is

noteworthy that one built by Fisher Body in Grand Blanc, MI in March of

1944 has the honor of representing all of the M4s that participated in

the Battle of the Bulge. Registration Number 3081532 was one

of 339 M4A3 Sherman tanks built in the Fisher Body Tank Arsenal in Grand

Blanc, MI in March 1944. Author's photo.

This is one of 5,368 M10 Tank

Destroyers built at Grand Blanc, MI. This late model, with no

attachment "knobs" welded on the hull and turret for added armor plate, is located at the

General George Patton Museum at Fort Knox, KY. Author's Photo.

A rare national treasure!!! This

Fisher Body T26E3 built in Grand Blanc, MI was one of the five Pershings

at the Remagen Bridge. It is on display at the Wright Museum of World

War II in Wolfeboro, NH. This excellent photograph was provided by

Bill Malone.

This M18 Hellcat is on display at the Buick

Museum in Flint, MI, only a mile or two from where it was assembled.

Author's Photo.

An M36 Jackson. The M36 was

built on the chassis of the Ford M10A1 Wolverine. Fisher Body

supplied the turrets to companies contracted with the conversions.

Author's photo added 12-27-2016.

The Fisher Body built turret.

Author's photo added 12-27-2016.

155mm and 8 inch Gun parts, Diesel Engine

parts and Torqmatic Transmission parts: The Die and Machine

plant was well diversified in the parts it built and the products or

weapons in which they were utilized.

Seen here is an M115 8 inch howitzer at the

Camp Atterbury outside museum in Edinburgh, IN. Author's Photo.

This M114 155mm howitzer is also at

the museum.

In the background is a 1950's era Honest John missile and mobile

launcher.

Author's photo.

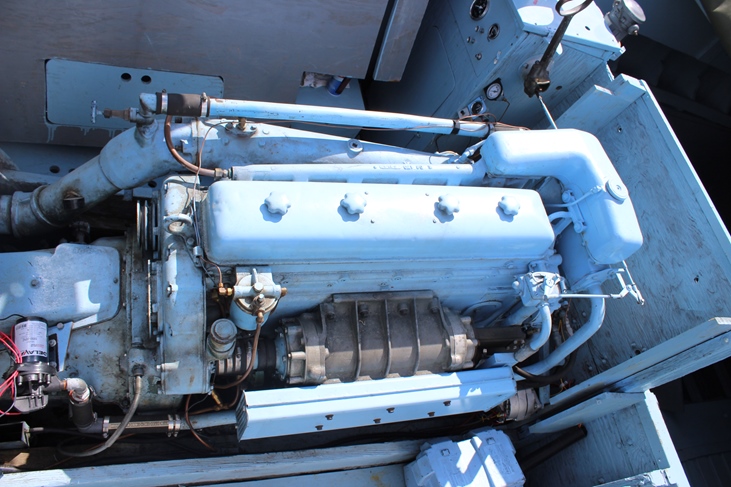

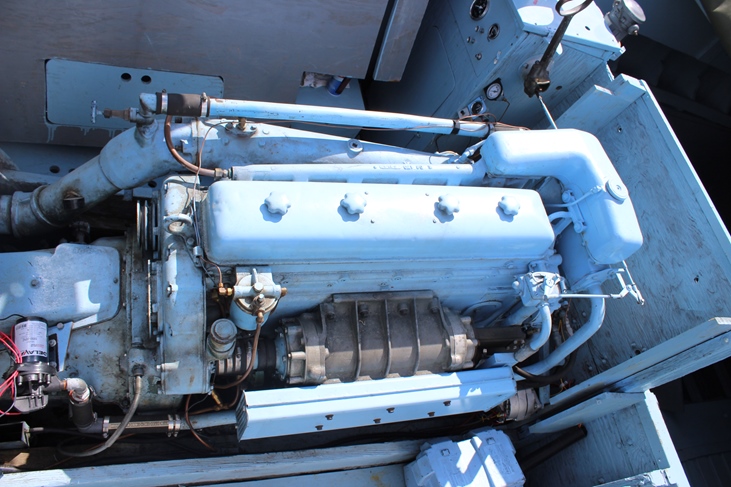

The Detroit Diesel Division of General

Motors built 193,000 diesel engines for many applications, including

this one photographed in the engine bay of an LCVP landing craft.

Author's photo.

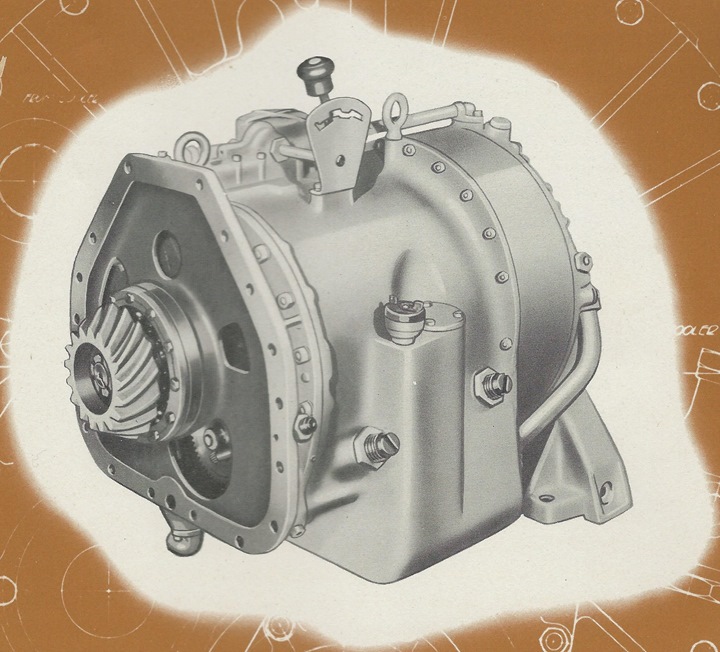

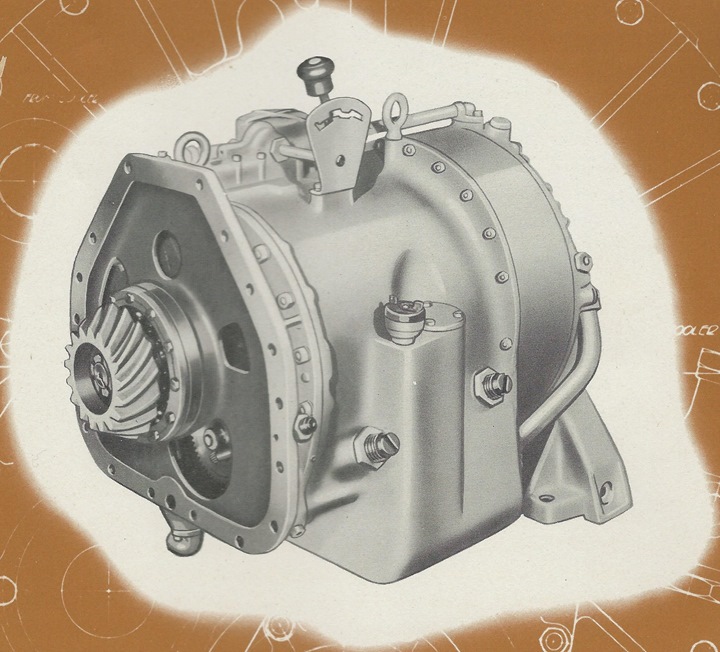

The Detroit Transmission Division of GM

built the 950-T Torqmatic transmission used in the Buick M18 Hellcat

tank destroyer. It also built the Torqmatic transmission for the

M26 Pershing built by both the Fisher Grand Blanc and Chrysler Tank

Arsenals.

This M18 Hellcat is on display at the Ropkey

Armor Museum in Crawfordsville, IN. Author's photo added

12-27-2016. .

Here is the Torqmatic transmission.

Author's photo added 12-27-2016.

"A Friendly Welcome to the Fisher Body Division Die and

Machine Plant"

The following six page pamphlet was

distributed to

visitors for an open house held in the mid to late 1950s. After

the title page there is a three page history of Fisher Body, a page on

employee benefits, and then the last page stating some facts and

figures.

|